Precision Engineering for Enhanced Clinical Accuracy

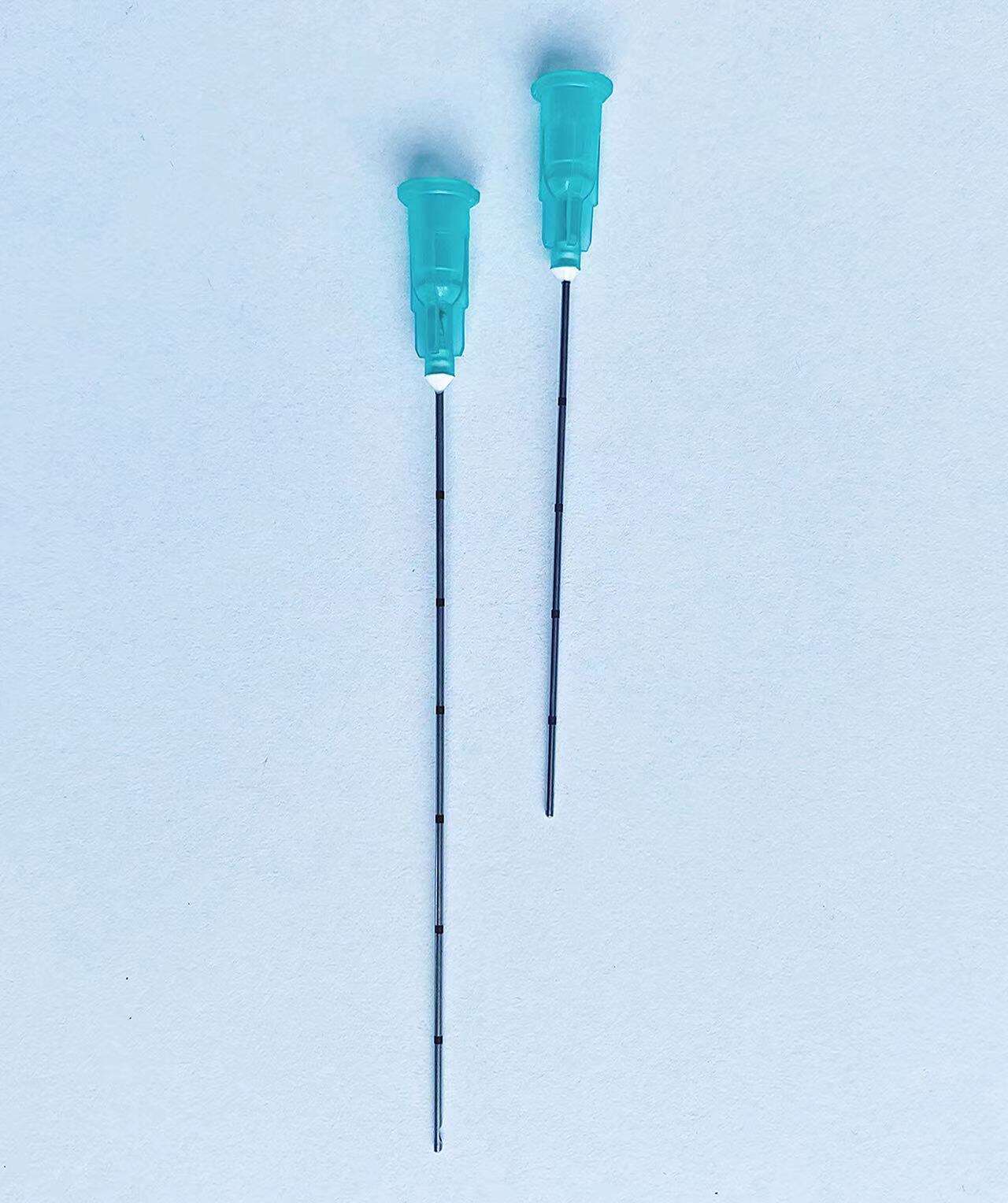

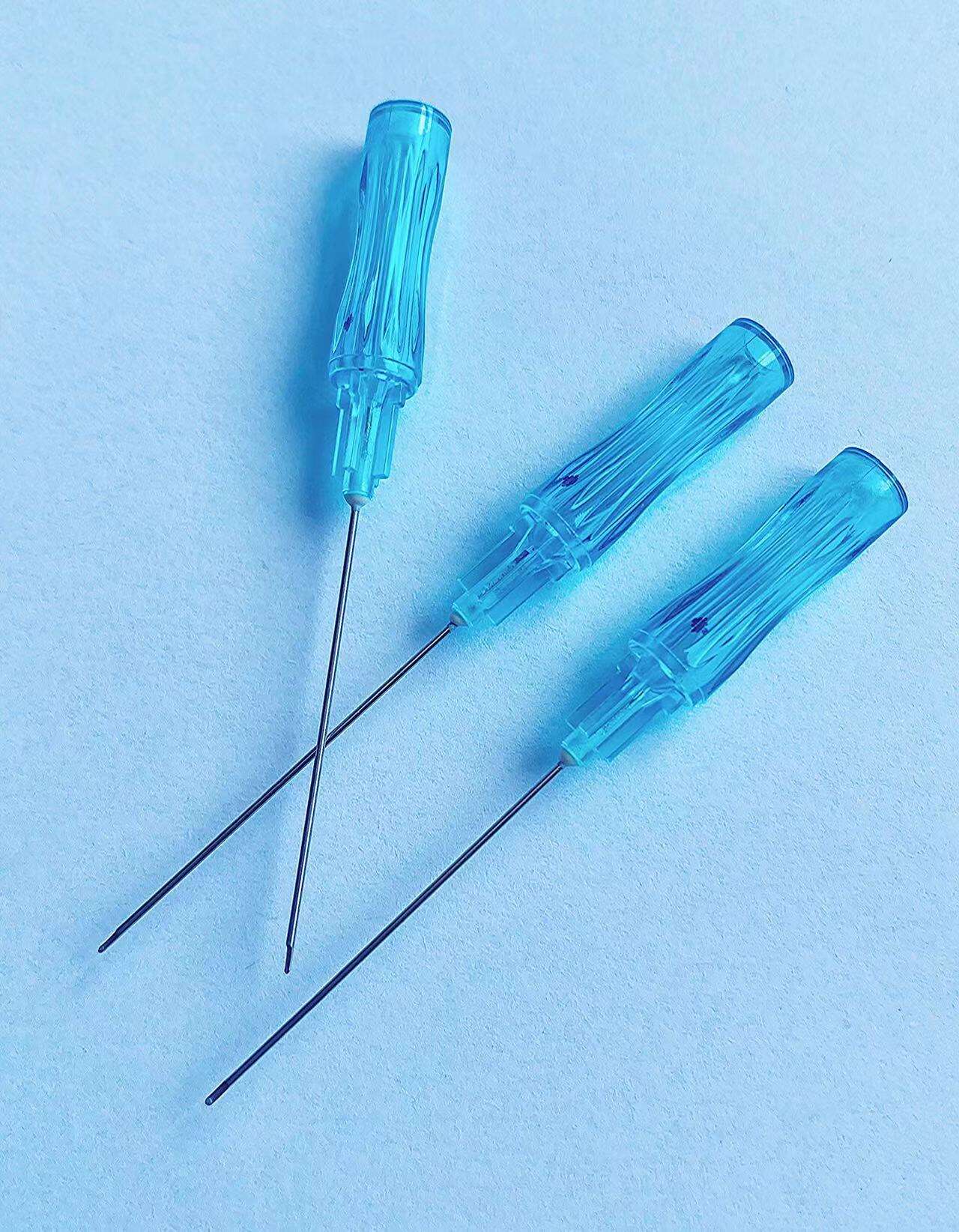

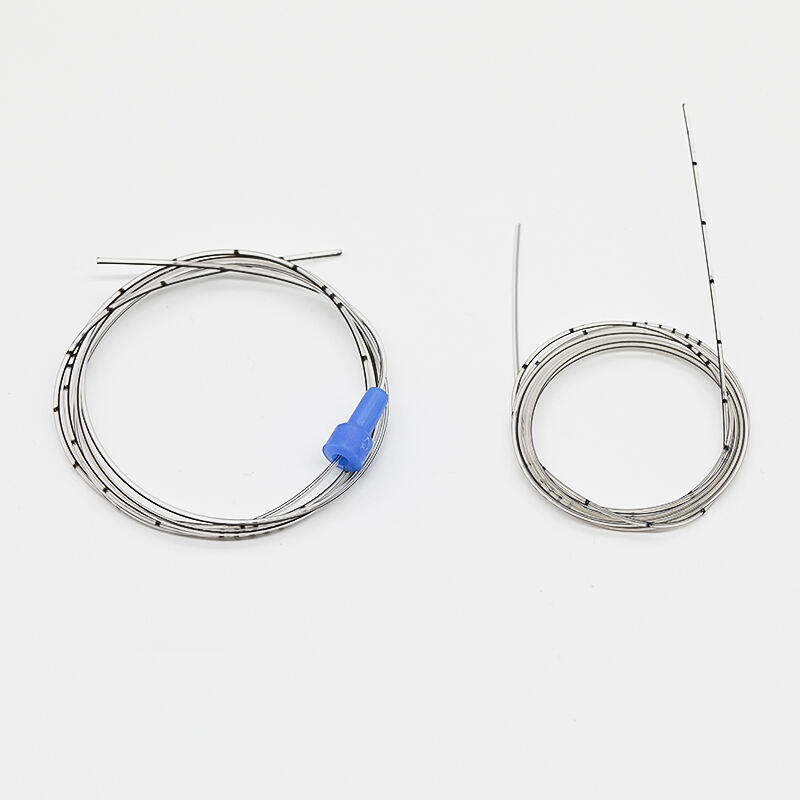

The embedding needle represents a pinnacle of precision engineering, incorporating advanced design elements that significantly enhance clinical accuracy and procedural success rates. The needle's carefully calibrated tip geometry utilizes specific angles and bevels that optimize tissue penetration characteristics while minimizing deflection during insertion. This precision engineering ensures the embedding needle follows the intended trajectory, reducing the likelihood of missing target tissues or inadvertently damaging surrounding structures. The shaft design incorporates micro-tolerances that maintain straightness and prevent bending under normal use conditions, crucial factors for maintaining accuracy during deep tissue procedures. Advanced manufacturing processes ensure the embedding needle maintains consistent wall thickness throughout its length, preventing weak points that could compromise structural integrity during use. The needle's connection interface features precision threading or locking mechanisms that create secure, leak-proof connections with syringes and other medical devices, preventing sample contamination or medication loss during procedures. Dimensional accuracy of the embedding needle enables reliable compatibility with standard medical equipment, including biopsy guns, aspiration devices, and injection systems used across various medical specialties. The engineering tolerances applied to the embedding needle manufacturing process ensure consistent performance characteristics across production batches, providing healthcare professionals with predictable and reliable instrumentation. Quality assurance protocols verify that each embedding needle meets exact specifications for length, diameter, and tip configuration, eliminating variability that could impact procedural outcomes. The precision engineering extends to the needle's marking systems, which provide accurate depth indicators and orientation references that assist medical professionals in achieving precise placement during procedures. Advanced computer-aided design and manufacturing processes optimize the embedding needle's structural properties, balancing flexibility with rigidity to provide optimal handling characteristics for various clinical applications. The engineering excellence of the embedding needle contributes to improved diagnostic accuracy by ensuring consistent sample collection quality and reducing artifacts that could interfere with pathological analysis.