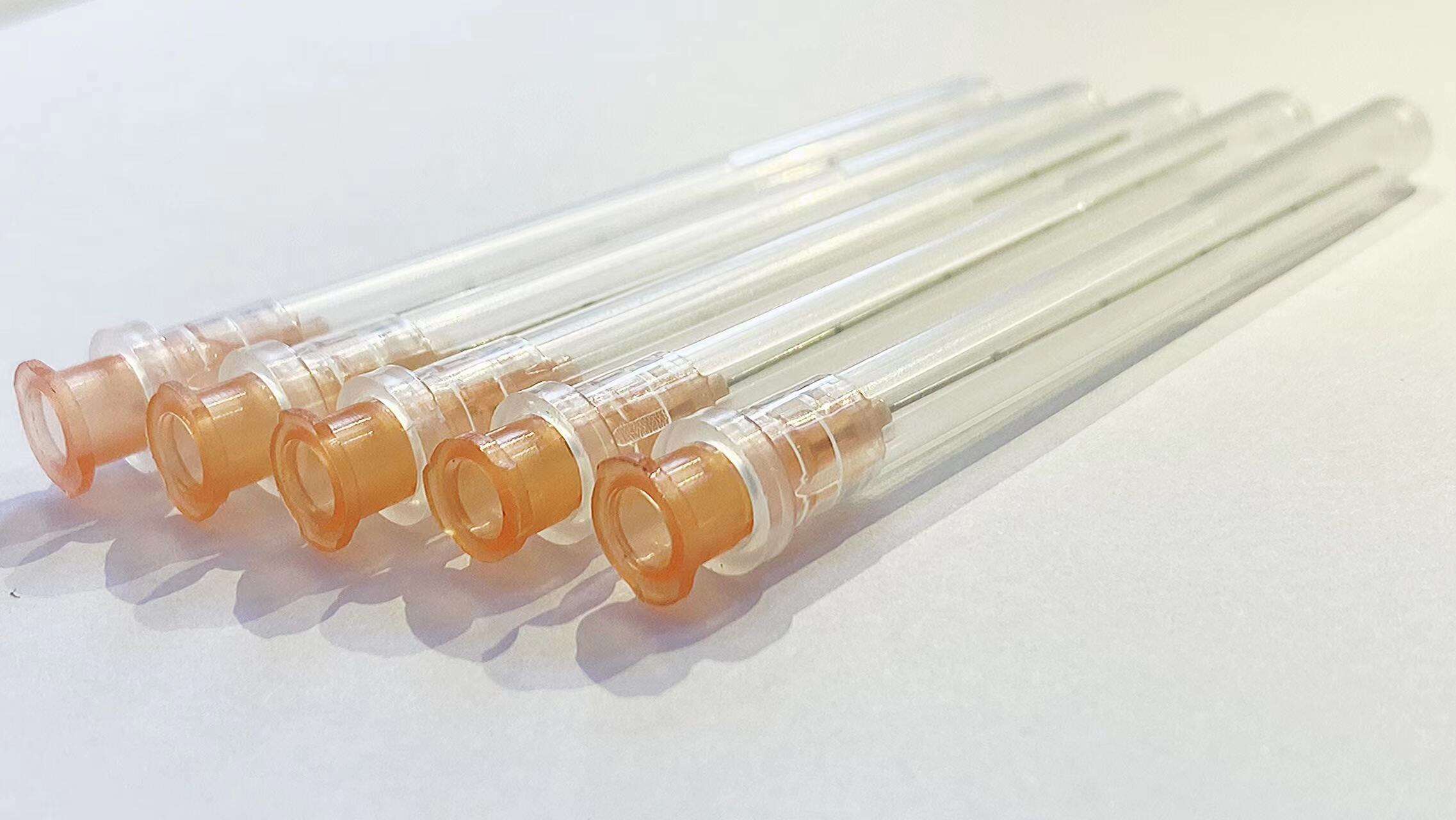

high quality embedding needle

The high quality embedding needle represents a revolutionary advancement in medical device technology, specifically engineered for precise tissue penetration and biocompatible material insertion procedures. This sophisticated instrument combines cutting-edge metallurgy with ergonomic design principles to deliver exceptional performance across diverse clinical applications. The high quality embedding needle features a ultra-sharp beveled tip manufactured from premium surgical-grade stainless steel, ensuring consistent penetration force while minimizing tissue trauma during insertion procedures. Its advanced surface treatment incorporates specialized coatings that reduce friction coefficients by up to 40 percent compared to conventional needles, resulting in smoother insertion dynamics and enhanced patient comfort. The needle's hollow core architecture enables precise delivery of embedding materials, including biocompatible polymers, therapeutic microspheres, and advanced implantable devices. Manufacturing processes employ state-of-the-art precision machining techniques with tolerances maintained within 0.001 millimeters, guaranteeing dimensional consistency across production batches. The high quality embedding needle incorporates innovative hub design features that provide secure connection interfaces with various delivery systems while maintaining sterility throughout procedures. Quality control protocols include comprehensive testing for structural integrity, biocompatibility certification, and sterility validation according to international medical device standards. Applications span multiple medical specialties including dermatology for cosmetic enhancement procedures, oncology for targeted drug delivery systems, and reconstructive surgery for tissue augmentation protocols. The needle's versatile design accommodates various gauge sizes from 18G to 30G, enabling customization for specific procedural requirements. Advanced materials science ensures the high quality embedding needle maintains sharp geometry throughout extended use while resisting deformation under high insertion pressures. Its compatibility with standard medical equipment makes integration seamless within existing clinical workflows, reducing training requirements and operational complexity for healthcare providers.