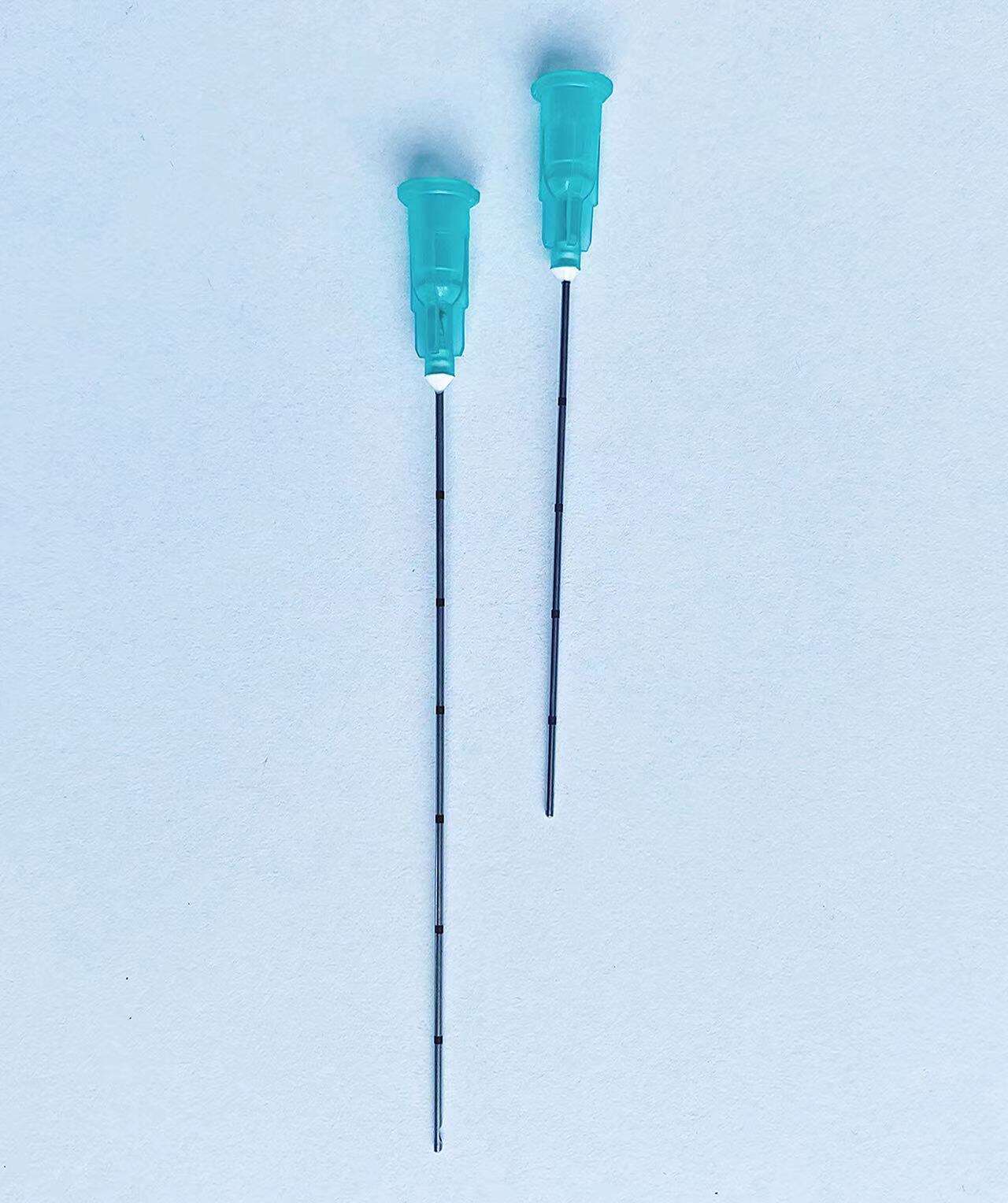

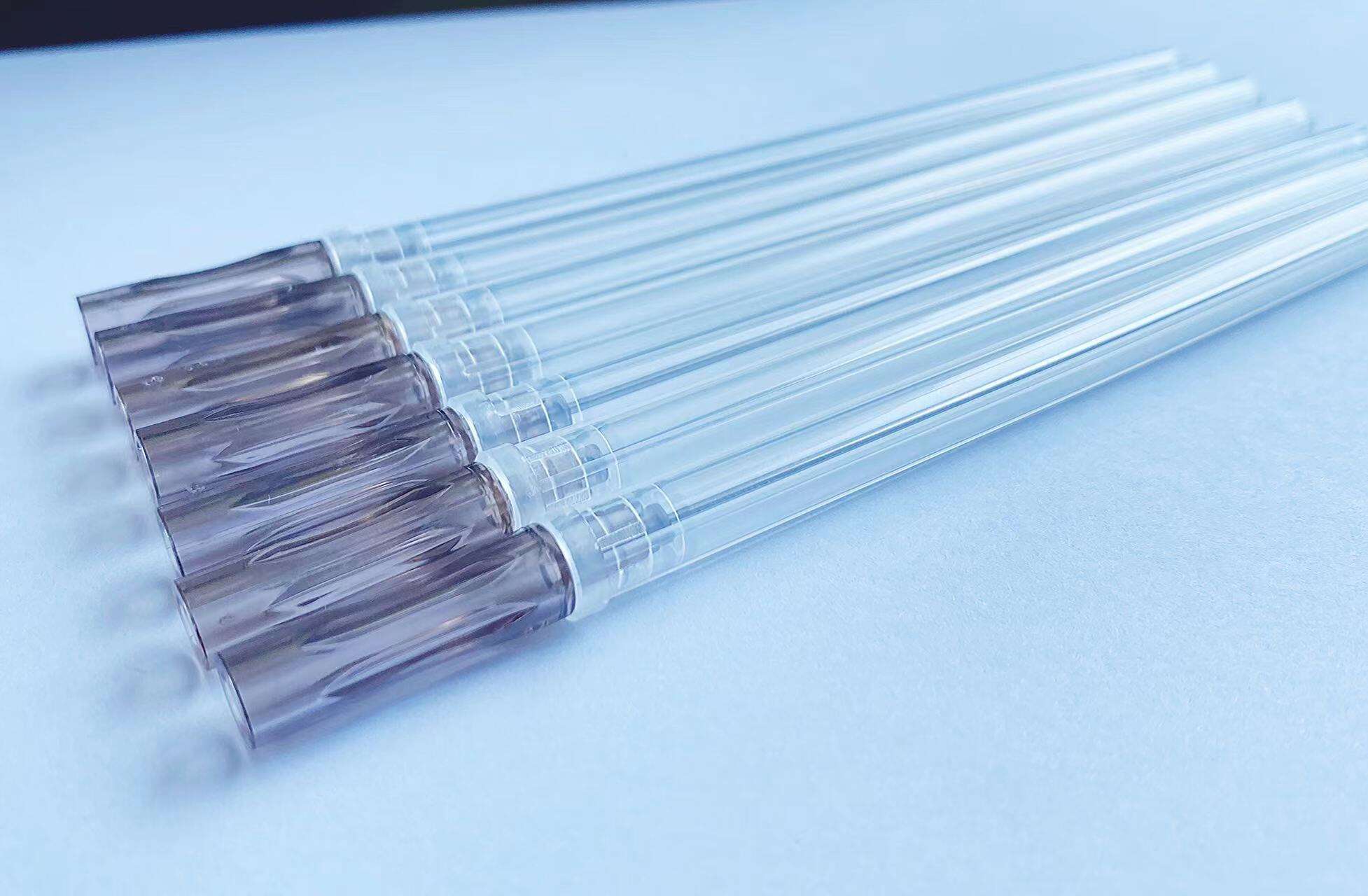

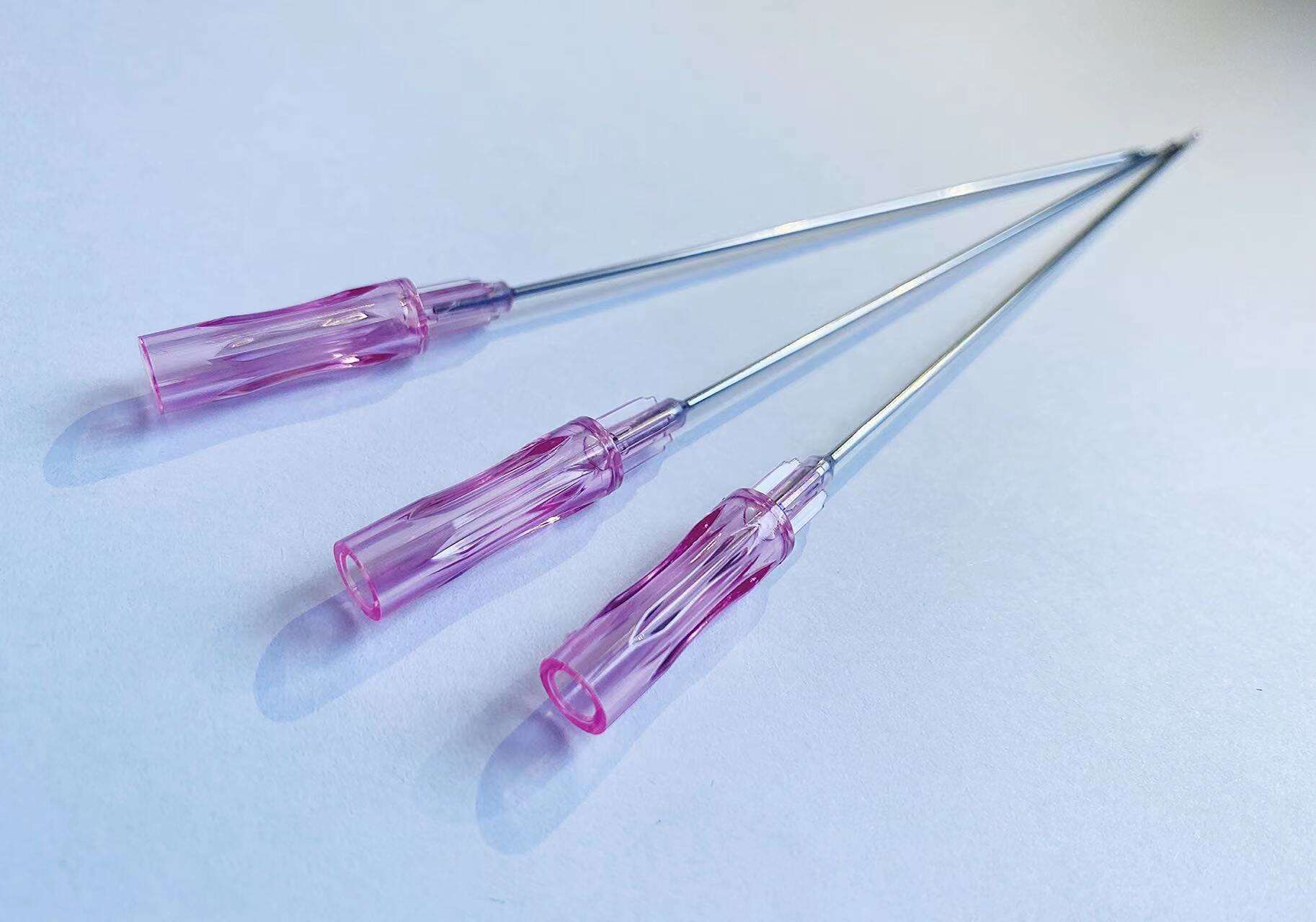

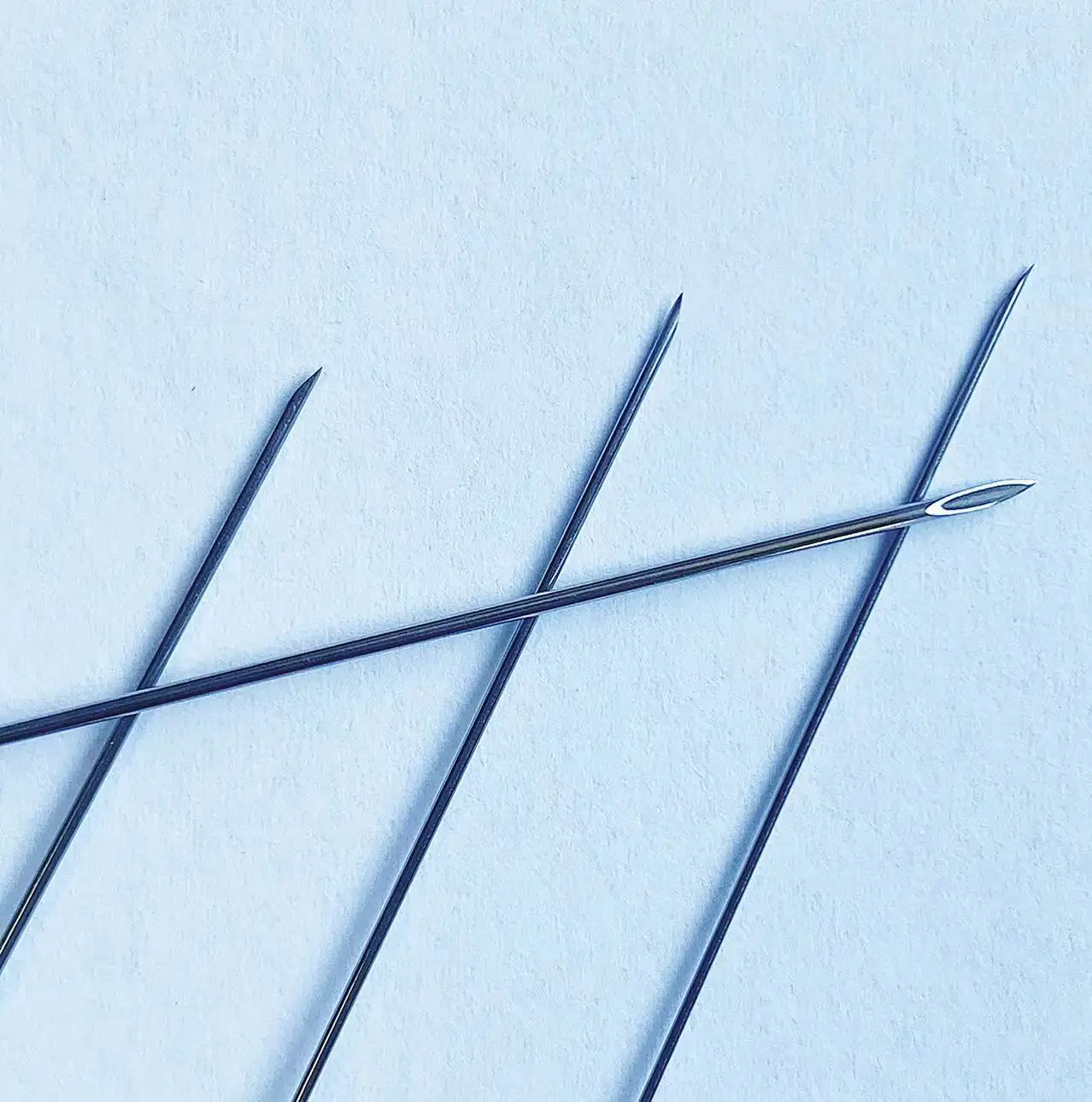

embedding needle supplies

Embedding needle supplies represent a crucial category of medical equipment designed to facilitate precise tissue penetration and material placement in various clinical procedures. These specialized instruments serve as essential tools in modern healthcare settings, enabling medical professionals to perform intricate procedures with enhanced accuracy and patient safety. The primary function of embedding needle supplies centers around their ability to create controlled pathways through tissue while minimizing trauma and ensuring optimal procedural outcomes. These needles incorporate advanced engineering principles that allow for smooth insertion, reduced friction, and consistent performance across diverse medical applications. The technological features of embedding needle supplies include precision-manufactured tips that maintain sharpness throughout extended use, specialized coatings that reduce tissue adhesion, and ergonomic designs that enhance practitioner control. Many embedding needle supplies feature graduated markings for precise depth measurement, ensuring accurate placement of materials or medications. The construction typically involves high-grade stainless steel or advanced alloy materials that provide exceptional durability while maintaining biocompatibility standards. Modern embedding needle supplies often incorporate innovative hub designs that facilitate secure connections to delivery systems while preventing accidental disconnection during procedures. The applications for embedding needle supplies span numerous medical specialties, including dermatology, plastic surgery, pain management, and interventional procedures. In aesthetic medicine, these needles enable precise placement of dermal fillers, botulinum toxins, and other therapeutic agents. Pain management specialists rely on embedding needle supplies for targeted injection therapies and nerve blocks. The versatility of these instruments makes them indispensable in both diagnostic and therapeutic procedures, where precision and reliability are paramount for successful patient outcomes.