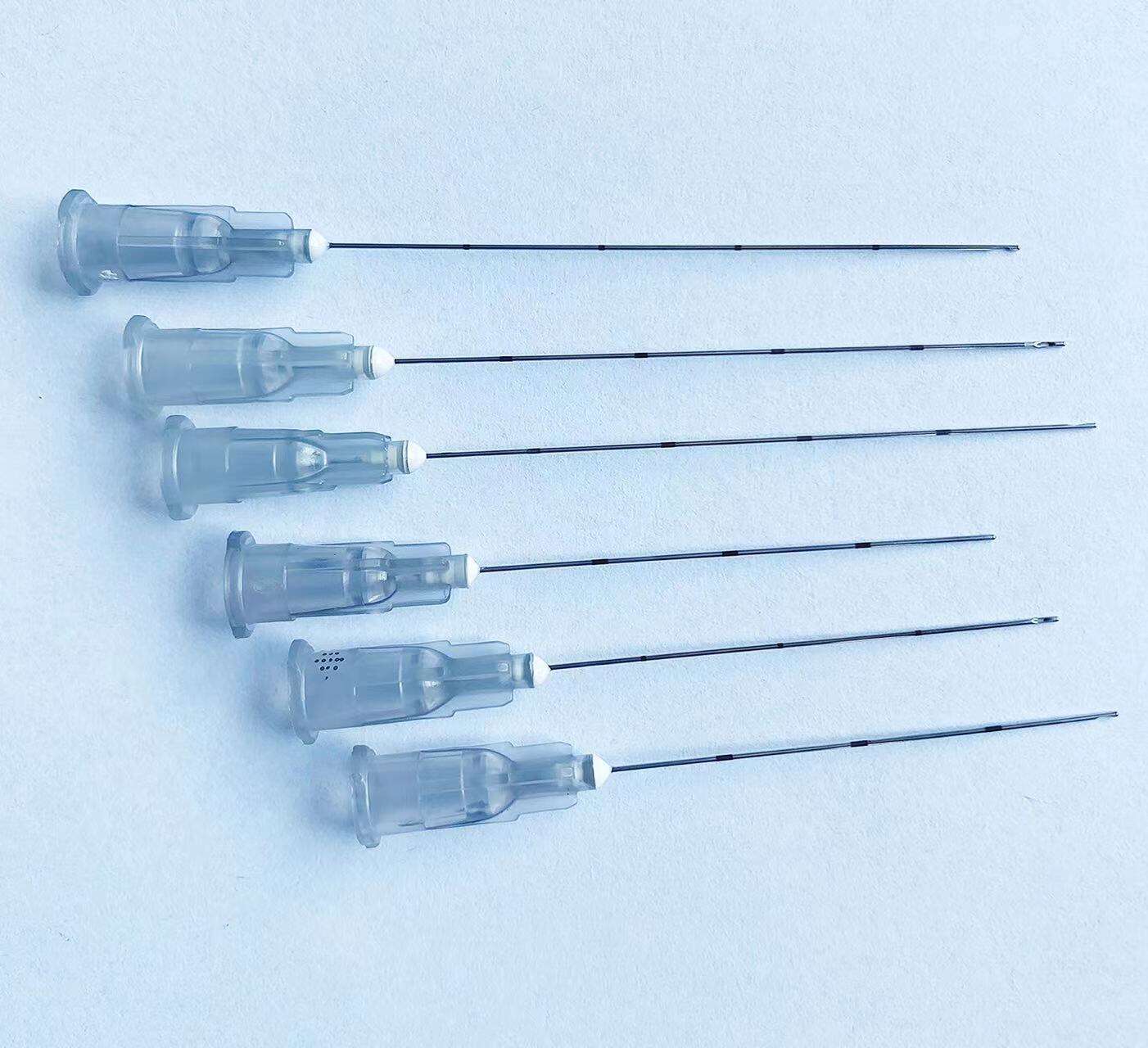

embedding needle made in china

The embedding needle made in China represents a pinnacle of precision engineering and manufacturing excellence in the medical device industry. These specialized instruments are meticulously crafted to meet the stringent requirements of modern medical procedures, particularly in aesthetic medicine, acupuncture, and various therapeutic applications. The embedding needle made in China combines traditional manufacturing expertise with cutting-edge technology to deliver products that satisfy international quality standards while maintaining competitive pricing. These needles feature ultra-sharp points engineered through advanced grinding techniques, ensuring minimal patient discomfort during insertion. The manufacturing process incorporates high-grade stainless steel materials that undergo rigorous quality control testing to guarantee sterility, durability, and consistent performance. Chinese manufacturers have invested heavily in automated production lines and cleanroom facilities to produce embedding needles that meet FDA and CE certification requirements. The technological features of the embedding needle made in China include precision-engineered tips with consistent sharpness, smooth surface finishes that reduce tissue trauma, and standardized dimensions that ensure compatibility with various medical devices. The needles undergo multiple sterilization processes including gamma radiation and ethylene oxide treatment to eliminate any potential contaminants. Applications for the embedding needle made in China span across multiple medical specialties including cosmetic procedures, thread lifting treatments, PDO thread insertions, and traditional Chinese medicine practices. Healthcare professionals worldwide rely on these needles for their reliability, cost-effectiveness, and superior performance characteristics. The manufacturing facilities in China utilize state-of-the-art machinery and maintain strict quality assurance protocols throughout the production cycle, from raw material inspection to final packaging, ensuring that each embedding needle made in China meets the highest standards of medical device manufacturing.