spinal needle cost

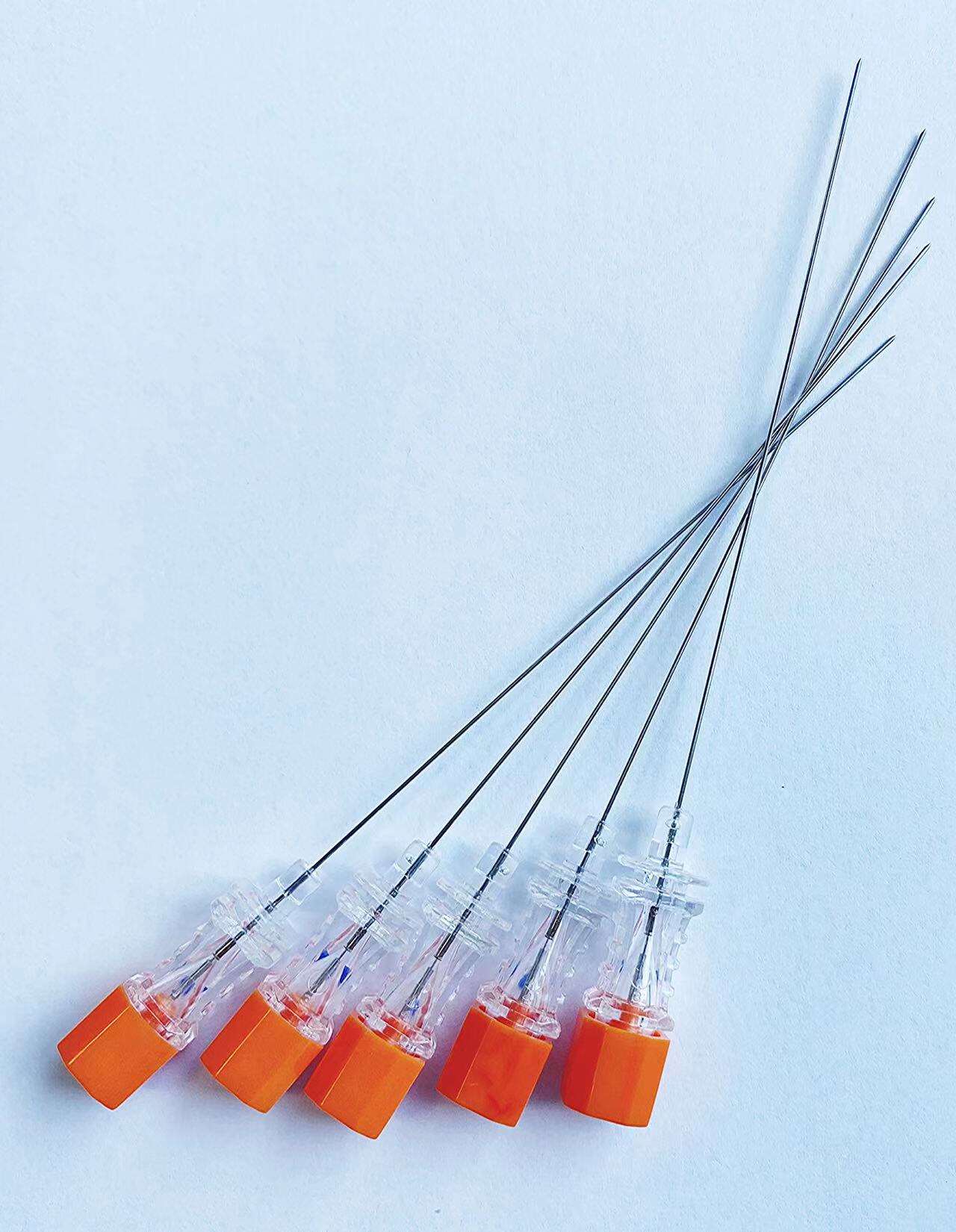

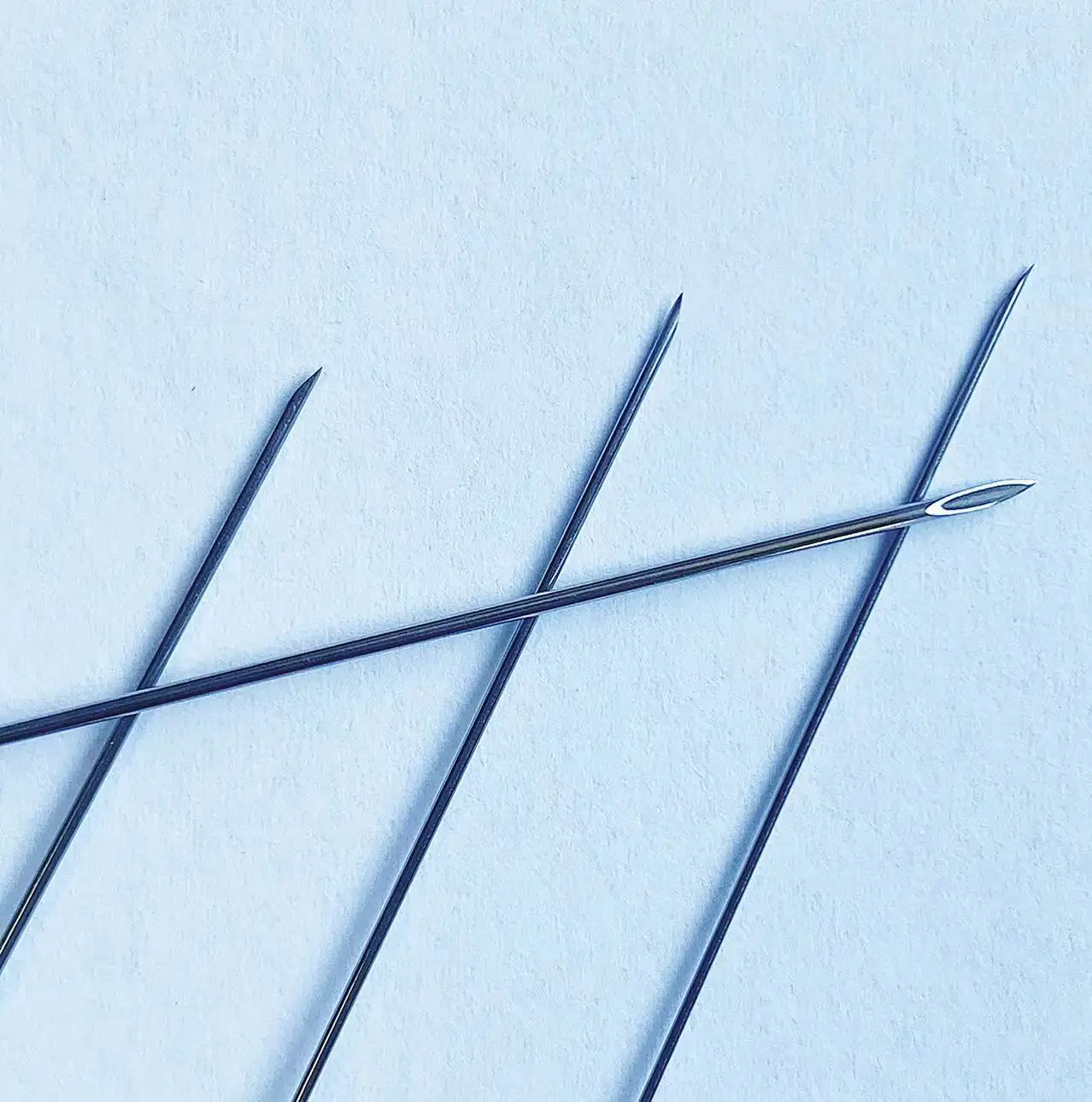

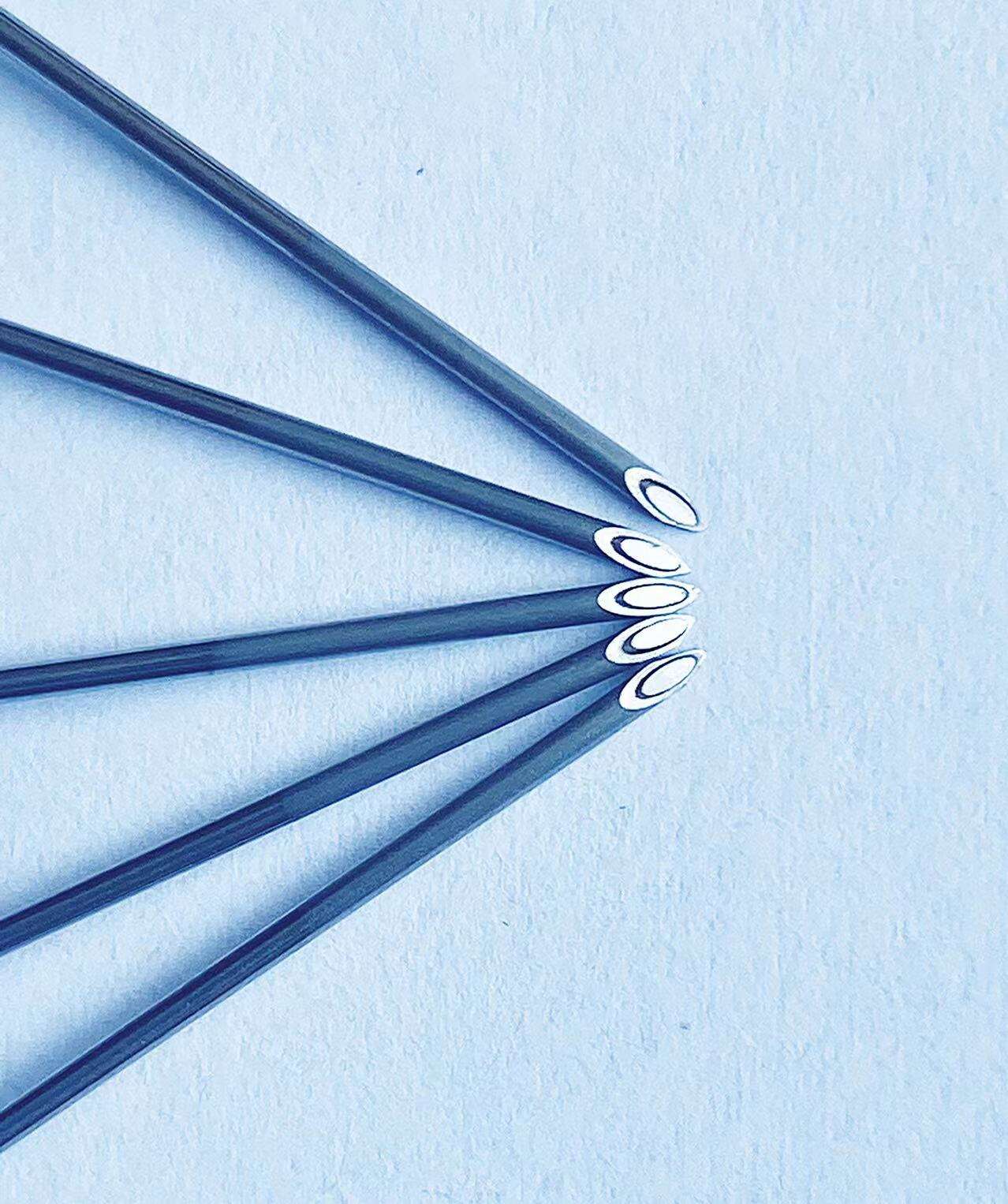

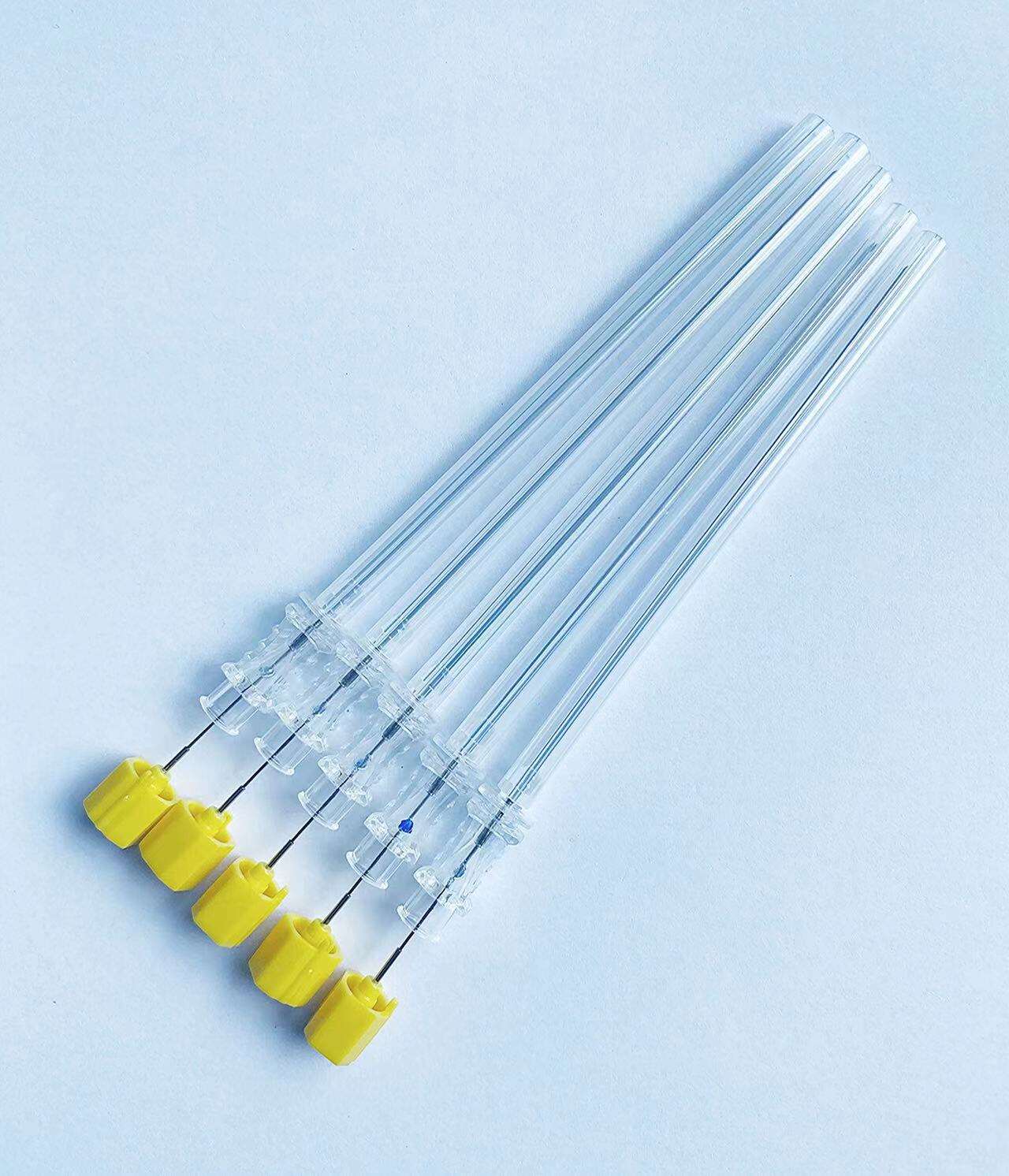

Understanding spinal needle cost involves examining the comprehensive value proposition of these essential medical instruments used in neuraxial procedures. Spinal needles represent critical components in anesthesia and diagnostic procedures, with their pricing reflecting sophisticated manufacturing standards and clinical performance requirements. The spinal needle cost encompasses various factors including materials, design complexity, and regulatory compliance standards that ensure patient safety and procedural success. These specialized medical devices serve primary functions in spinal anesthesia, lumbar punctures, and cerebrospinal fluid sampling procedures. Modern spinal needles incorporate advanced technological features such as pencil-point tip designs that minimize tissue trauma and reduce post-dural puncture headache incidence. The manufacturing process involves precision engineering to create ultra-sharp, beveled tips with optimal cutting angles for smooth tissue penetration. Gauge sizes typically range from 22G to 27G, with smaller gauges offering reduced trauma but requiring greater insertion force. The spinal needle cost reflects quality materials including surgical-grade stainless steel construction that provides excellent durability and biocompatibility. Ergonomic hub designs facilitate precise handling during procedures, while transparent hubs allow visual confirmation of cerebrospinal fluid flow. Applications extend beyond anesthesia to include diagnostic procedures, intrathecal medication administration, and research sampling. The technological advancement in spinal needle design has significantly improved patient outcomes while justifying the associated costs. Manufacturing facilities must maintain strict quality control standards and regulatory compliance, contributing to the overall spinal needle cost structure. Healthcare facilities evaluate these costs against clinical benefits, considering factors such as reduced complication rates, improved patient satisfaction, and enhanced procedural efficiency. The investment in quality spinal needles ultimately translates to better clinical outcomes and reduced liability risks for medical practitioners and institutions.