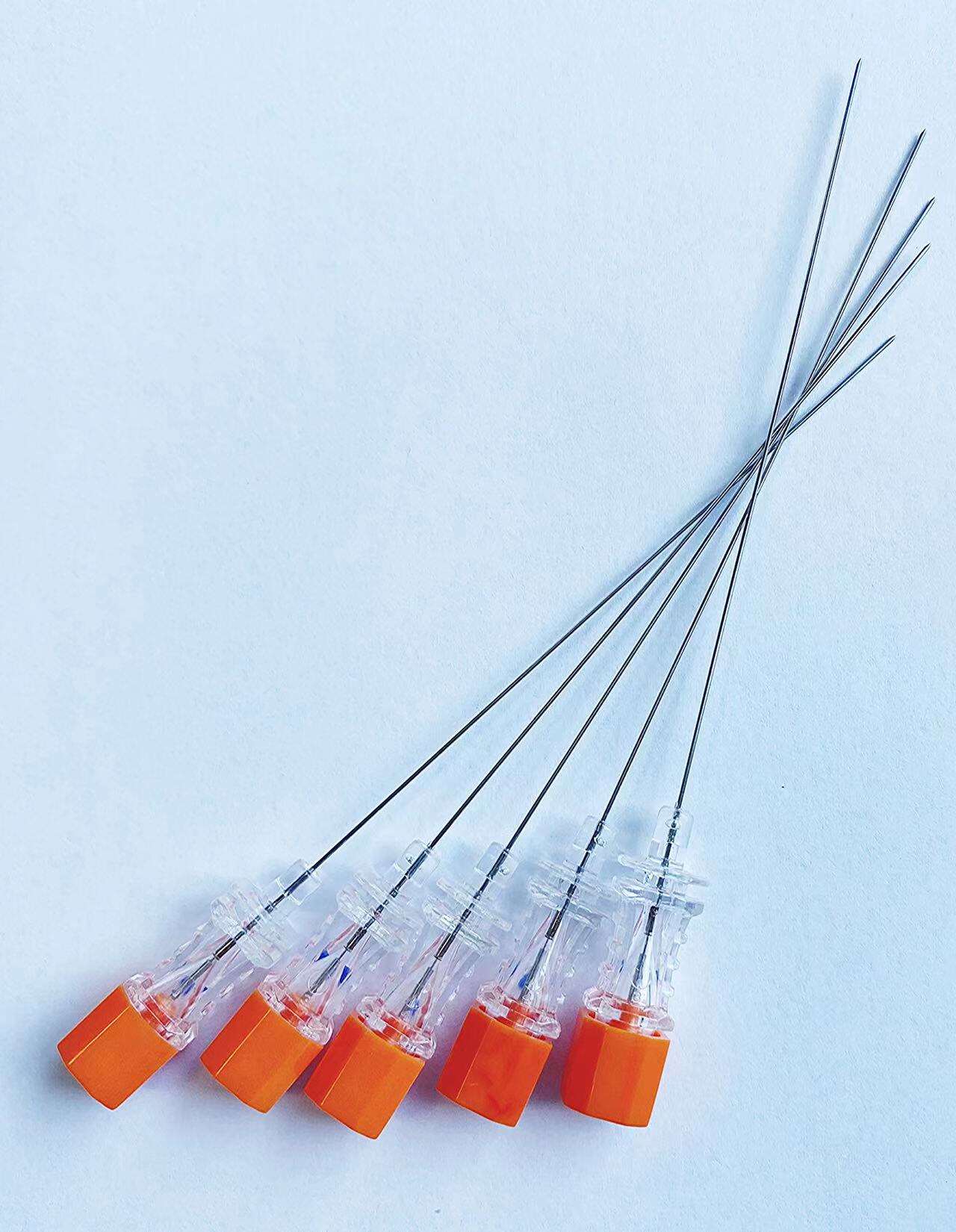

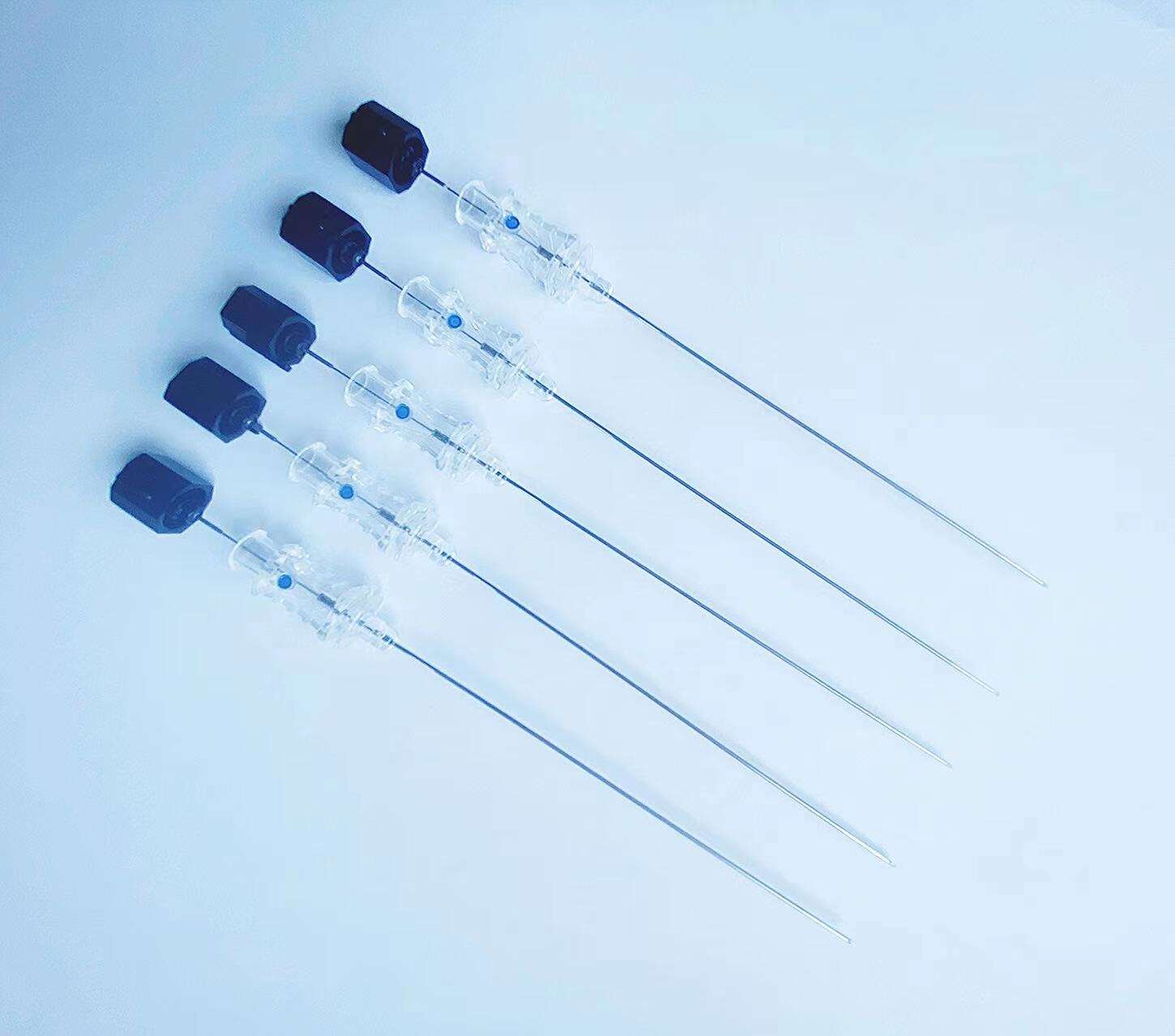

Superior Construction Quality and Durability

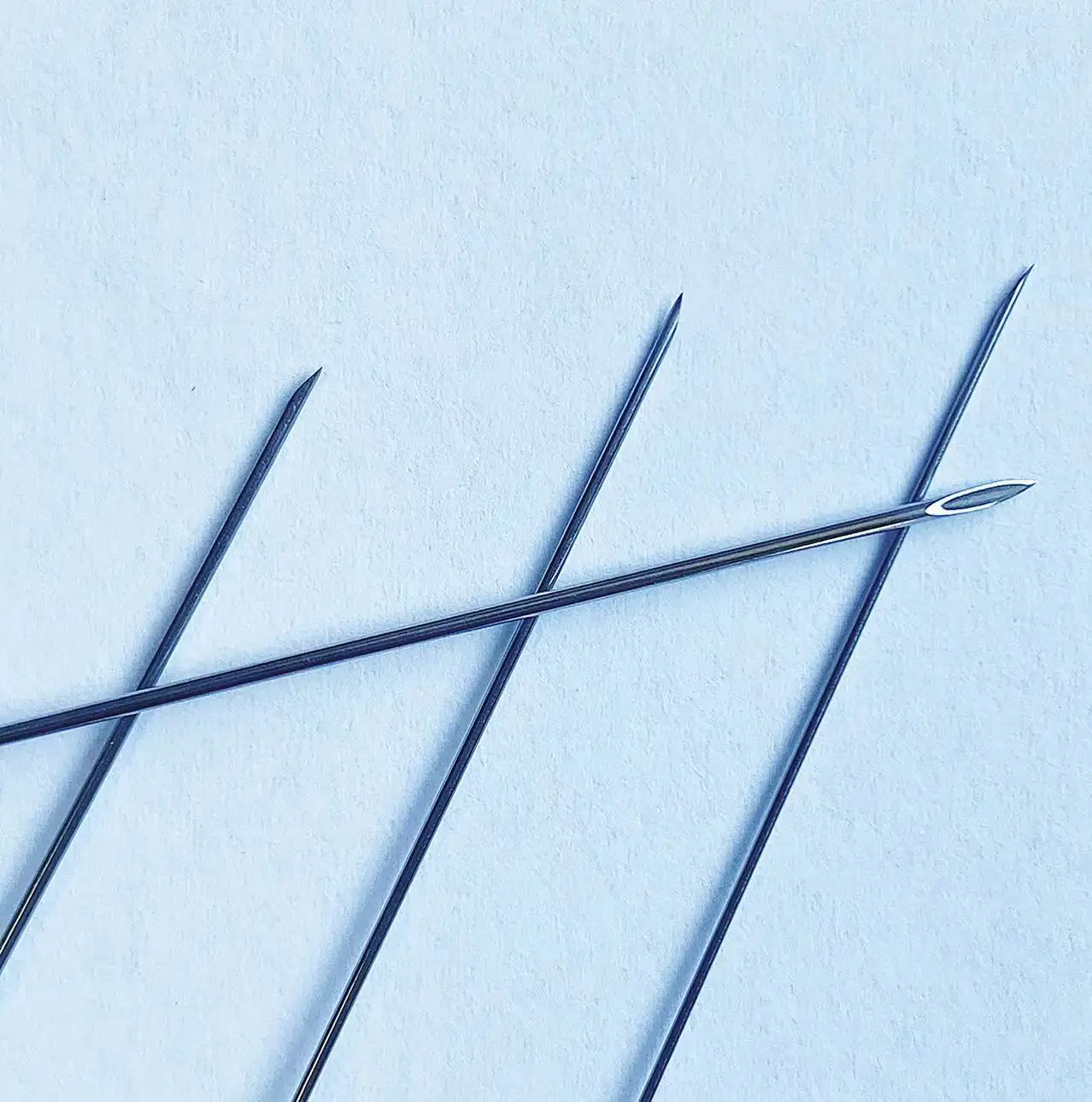

The black spinal needle exemplifies superior construction quality through its implementation of advanced manufacturing processes and premium materials selection. This commitment to excellence begins with the careful selection of medical-grade stainless steel alloys that provide optimal balance between strength, flexibility, and biocompatibility. The manufacturing process incorporates precision machining techniques that achieve tolerances measured in micrometers, ensuring consistent performance characteristics across every production unit. Heat treatment protocols applied during manufacturing enhance the structural integrity of the black spinal needle while maintaining the flexibility necessary for safe clinical use. Quality control measures implemented throughout production include multiple inspection points that verify dimensional accuracy, surface finish quality, and mechanical properties. The superior construction quality of the black spinal needle directly translates to enhanced reliability during critical medical procedures where equipment failure is simply not acceptable. Healthcare providers depend on instruments that perform predictably under demanding clinical conditions, and the black spinal needle delivers this reliability through its robust construction methodology. The durability characteristics of this instrument extend beyond basic structural integrity to include resistance to corrosion, mechanical wear, and sterilization stresses encountered during typical healthcare facility protocols. Advanced surface treatments applied to the black spinal needle enhance its resistance to biological contamination while maintaining optimal insertion characteristics. The construction quality ensures that the needle maintains its geometric precision throughout multiple sterilization cycles, preventing degradation that could compromise procedural safety or efficacy. Manufacturing quality systems certified to international medical device standards guarantee that each black spinal needle meets stringent performance requirements before reaching healthcare facilities. The investment in superior construction quality ultimately provides healthcare facilities with instruments that offer excellent value through reduced replacement frequency and improved procedural outcomes. Durability testing protocols subject the black spinal needle to accelerated aging conditions that simulate years of clinical use, ensuring long-term performance reliability. The construction methodology incorporates lessons learned from decades of clinical feedback, addressing common failure modes that affect conventional needle designs. Healthcare professionals recognize the superior construction quality of the black spinal needle through its consistent performance characteristics and extended service life. The manufacturing precision achieved in producing the black spinal needle enables healthcare providers to develop standardized protocols with confidence in equipment performance consistency. This superior construction quality contributes significantly to the overall cost-effectiveness of the black spinal needle by reducing procedural complications and improving success rates.