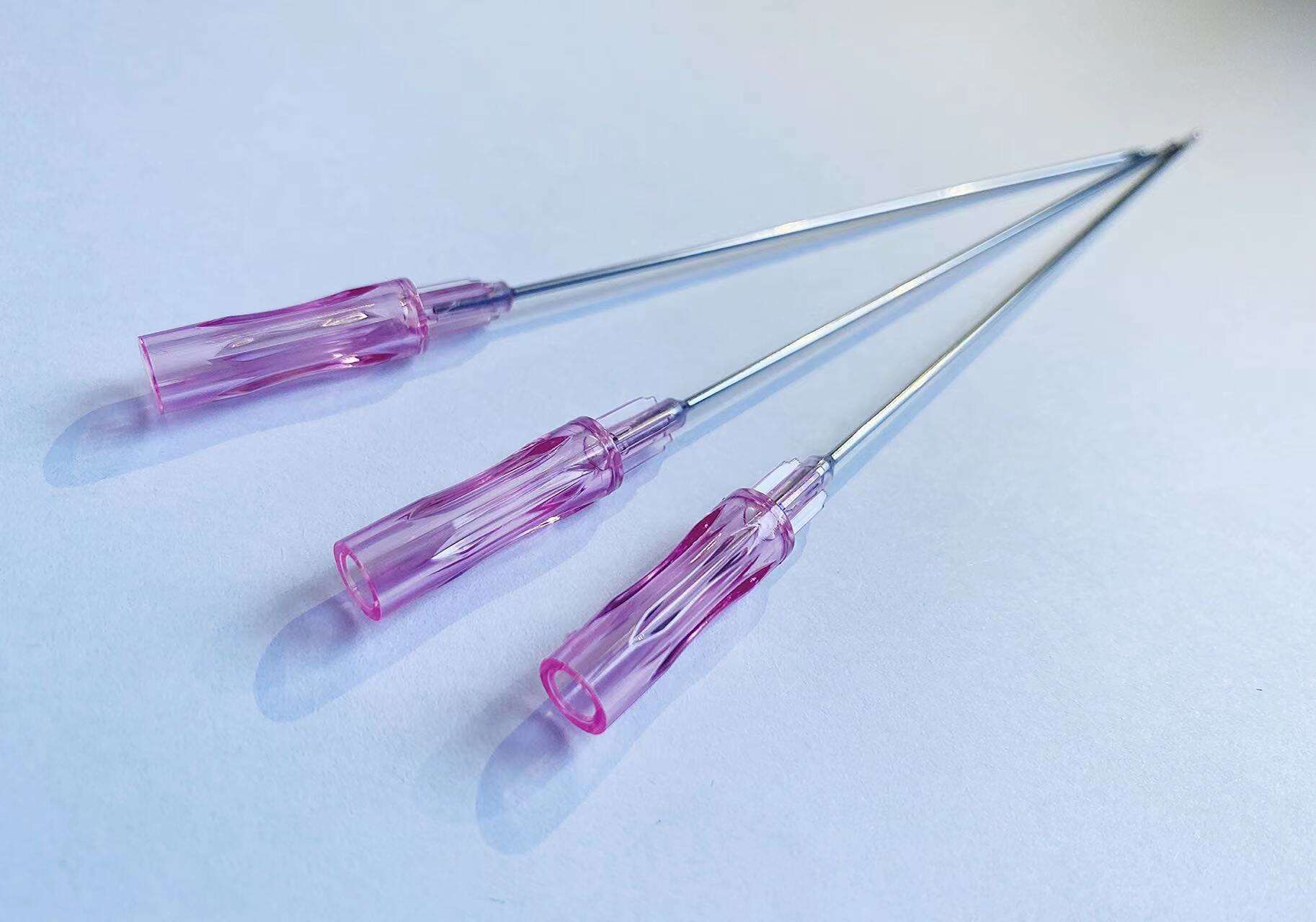

cutting spinal needle

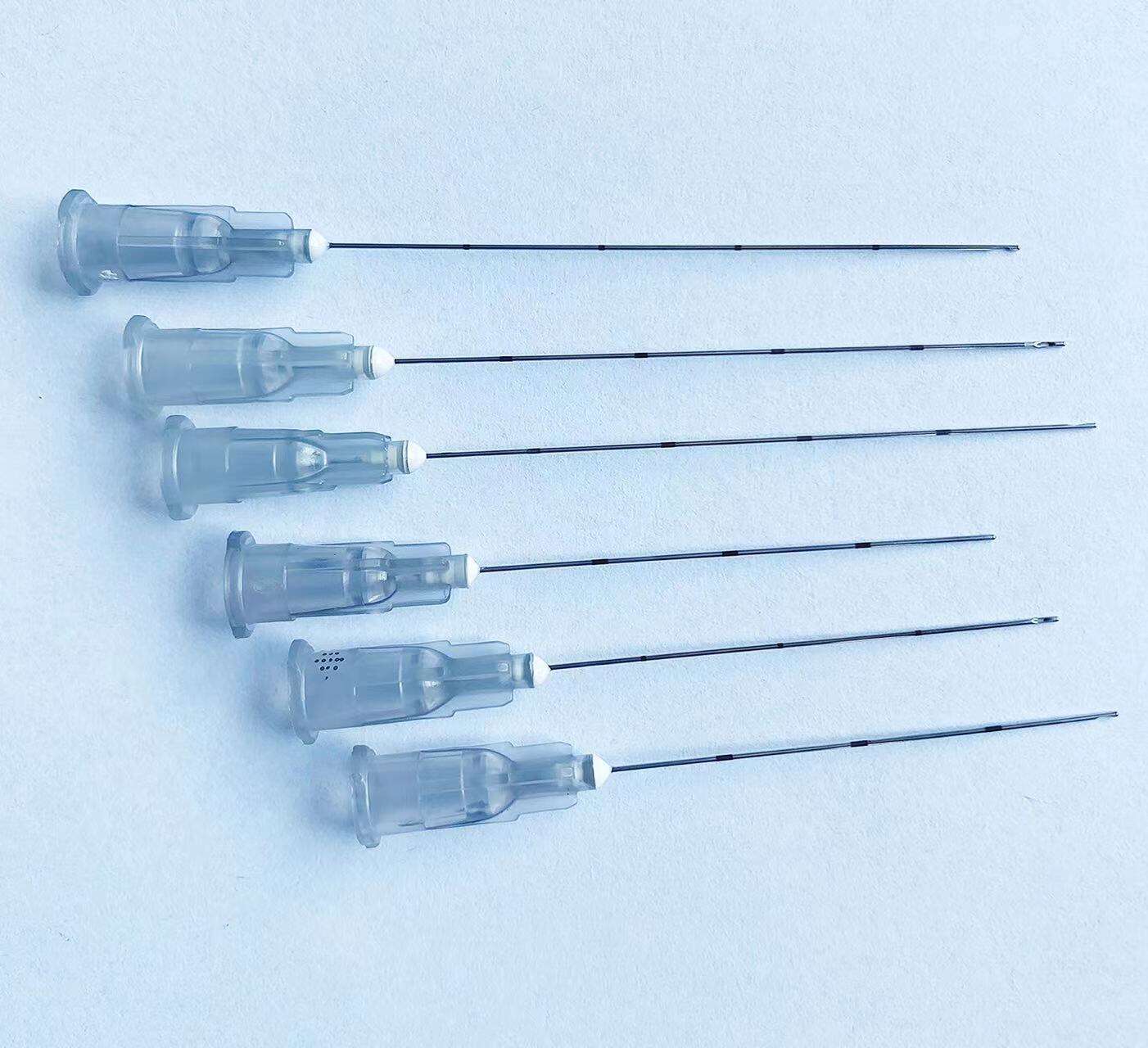

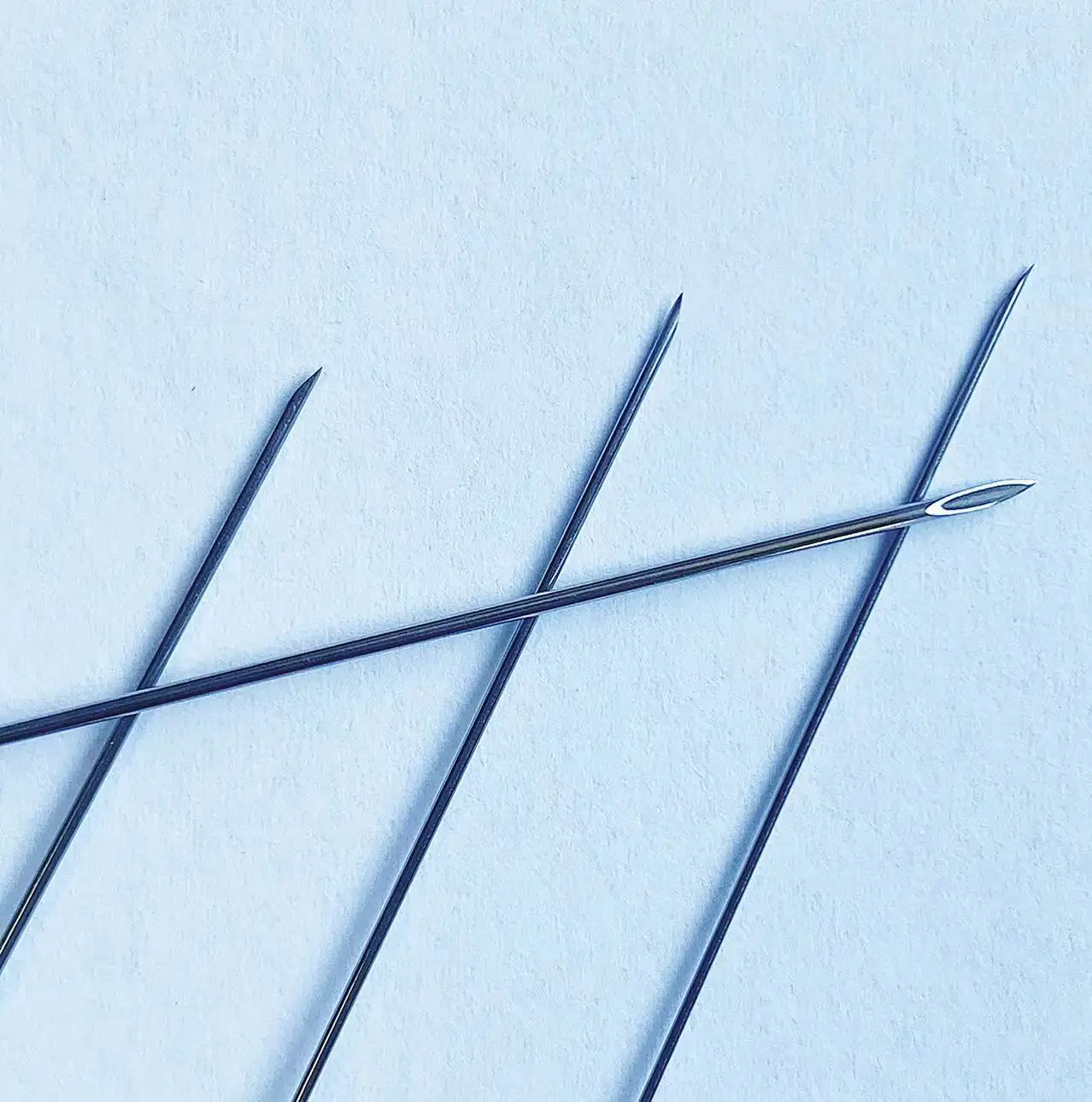

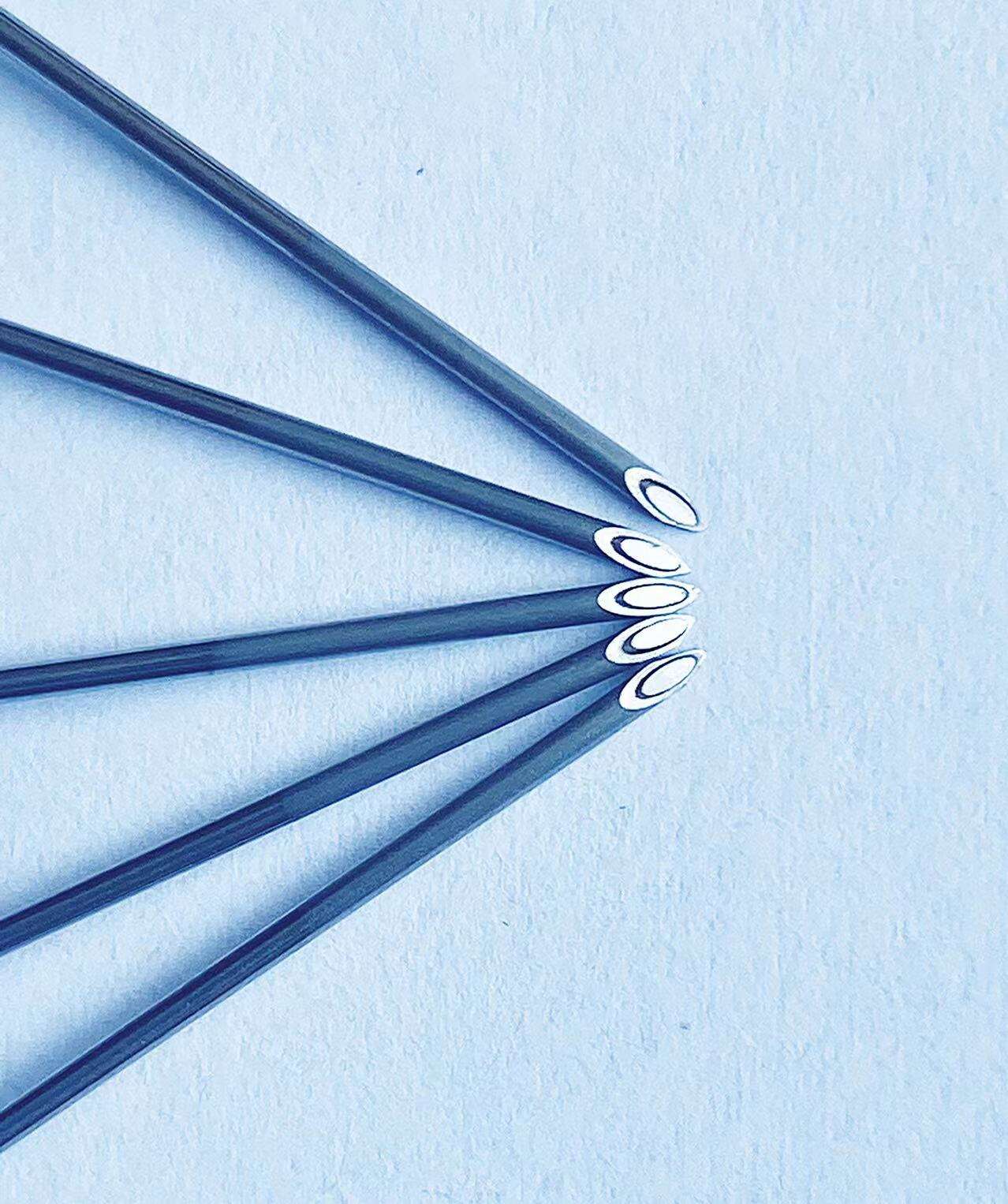

The cutting spinal needle represents a revolutionary advancement in modern medical instrumentation, specifically designed for precise and effective spinal procedures. This sophisticated medical device serves as an essential tool for healthcare professionals performing lumbar punctures, spinal anesthesia, and cerebrospinal fluid collection procedures. The cutting spinal needle features a sharp, beveled tip that creates clean, controlled tissue penetration while minimizing patient discomfort and reducing the risk of complications. Healthcare providers rely on this specialized instrument to access the subarachnoid space with exceptional accuracy and safety. The cutting spinal needle incorporates advanced metallurgical engineering, utilizing high-grade stainless steel construction that ensures optimal strength, flexibility, and corrosion resistance. Its ergonomic design facilitates comfortable handling during extended procedures, while the precision-engineered cutting edge maintains sharpness throughout multiple uses. The needle's hollow bore allows for smooth fluid aspiration and injection, making it indispensable for diagnostic and therapeutic applications. Medical professionals appreciate the cutting spinal needle's consistent performance across various patient populations, from pediatric to geriatric cases. The device's standardized sizing system enables practitioners to select the appropriate gauge and length for specific procedural requirements. Quality control measures ensure each cutting spinal needle meets stringent medical device standards, providing healthcare facilities with reliable instrumentation. The manufacturing process incorporates rigorous testing protocols to verify sterility, structural integrity, and functional performance. Modern cutting spinal needle designs often feature enhanced visibility markers and depth indicators, assisting clinicians in achieving optimal placement. The device's compatibility with standard medical equipment and accessories streamlines workflow efficiency in clinical settings. Healthcare institutions worldwide have adopted the cutting spinal needle as a preferred choice for spinal procedures, recognizing its superior performance characteristics and patient safety profile. The instrument's versatility extends across multiple medical specialties, including anesthesiology, neurology, and emergency medicine, making it a valuable addition to any medical facility's inventory.