Advanced Precision Engineering for Superior Clinical Performance

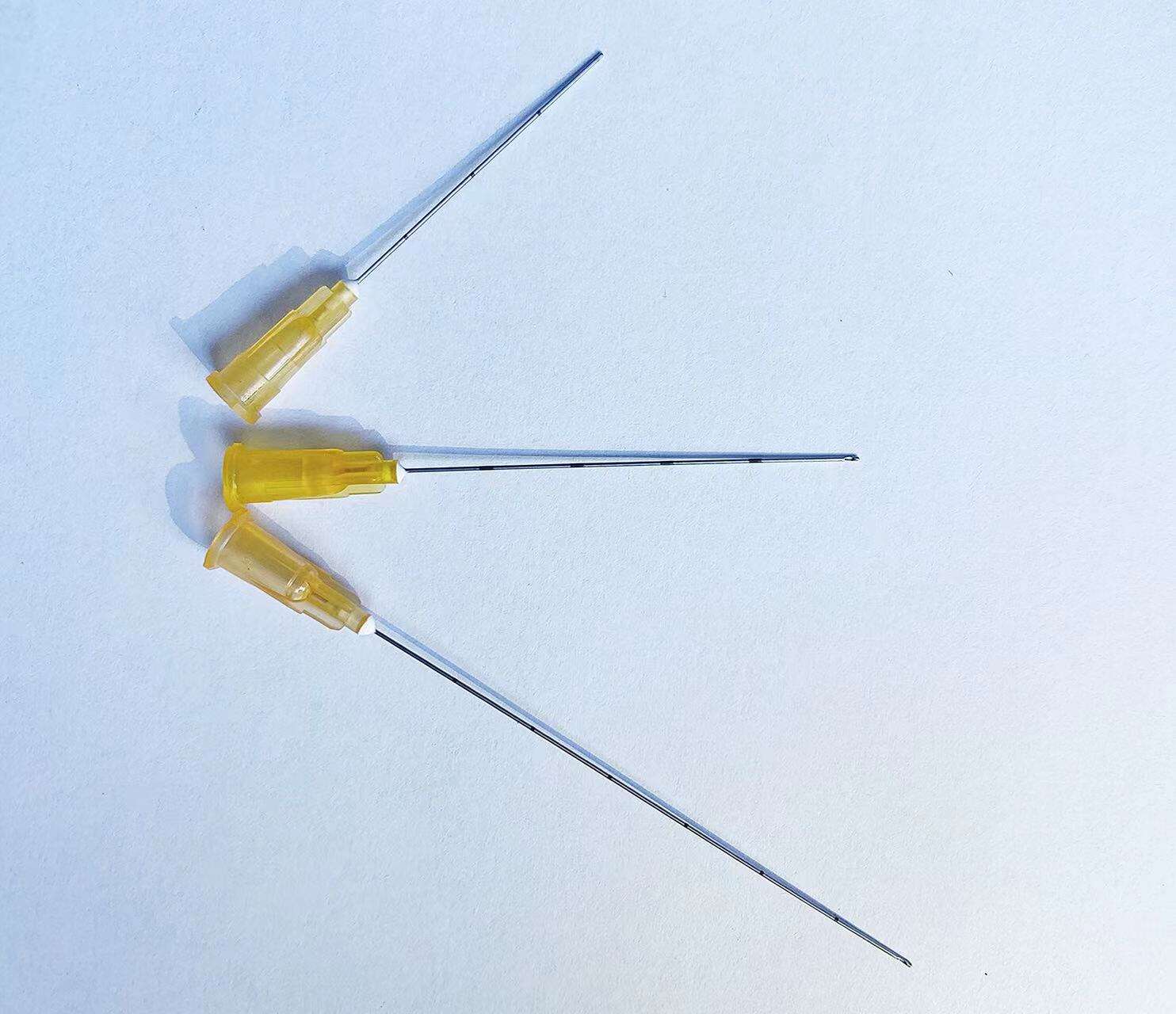

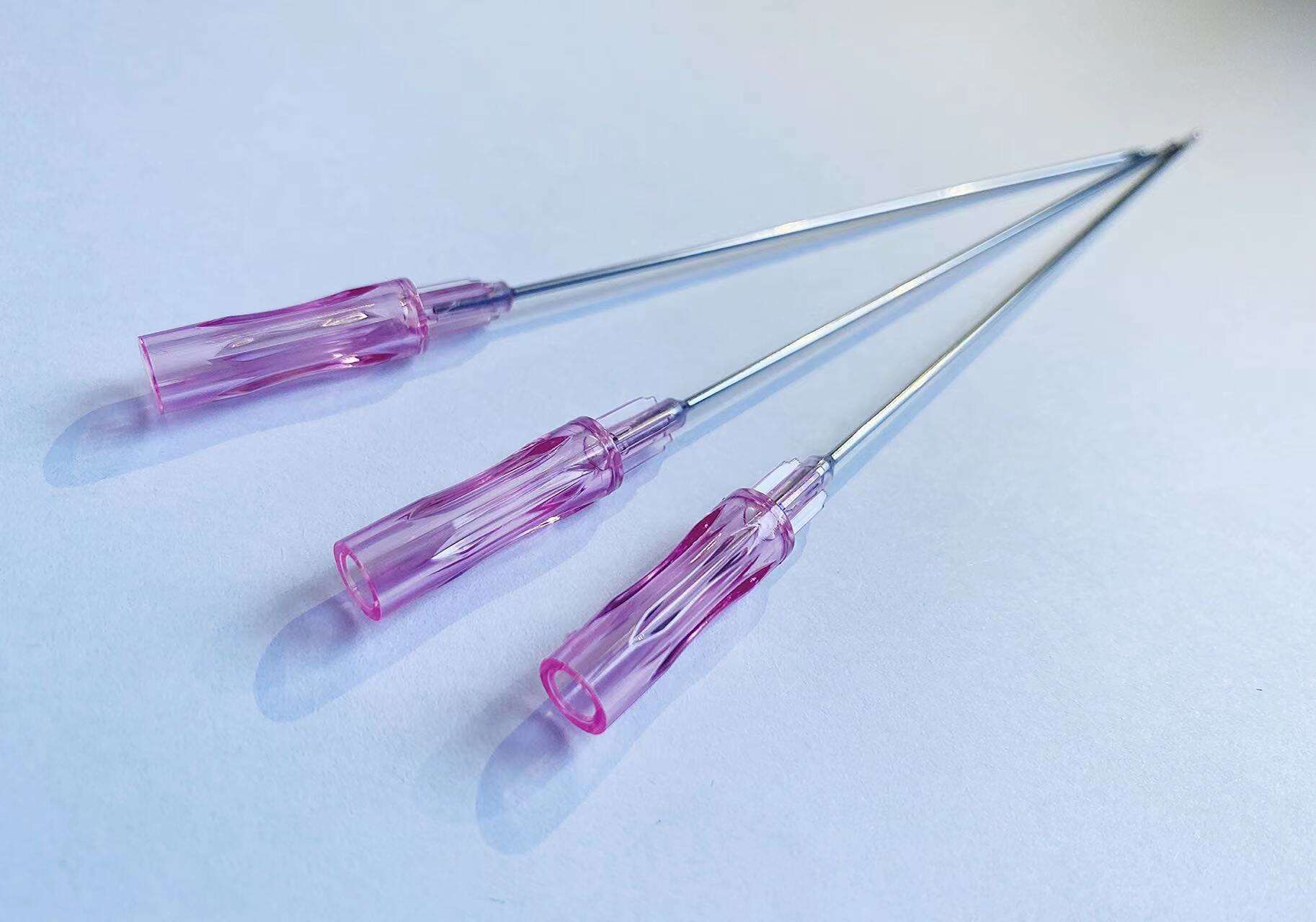

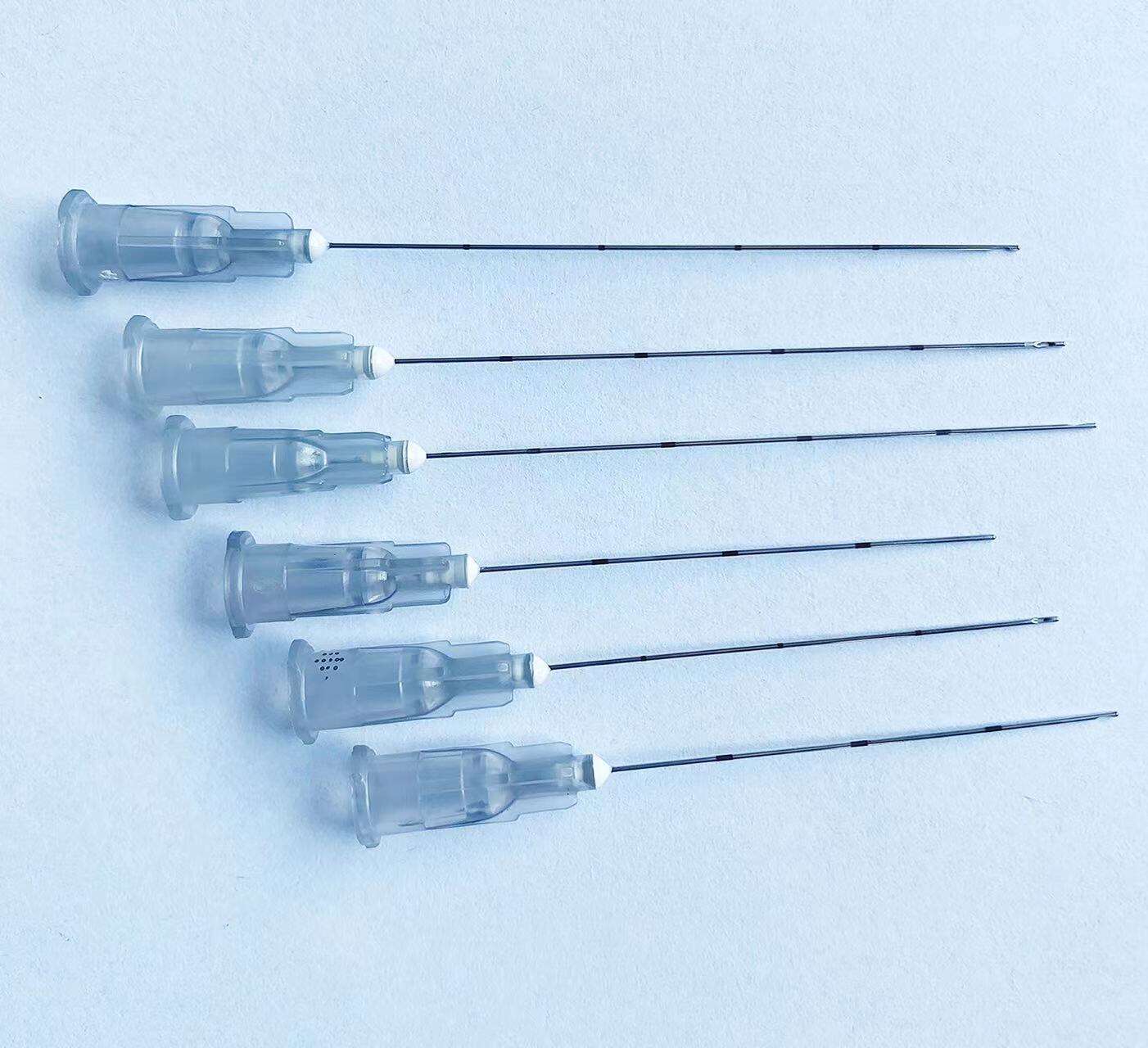

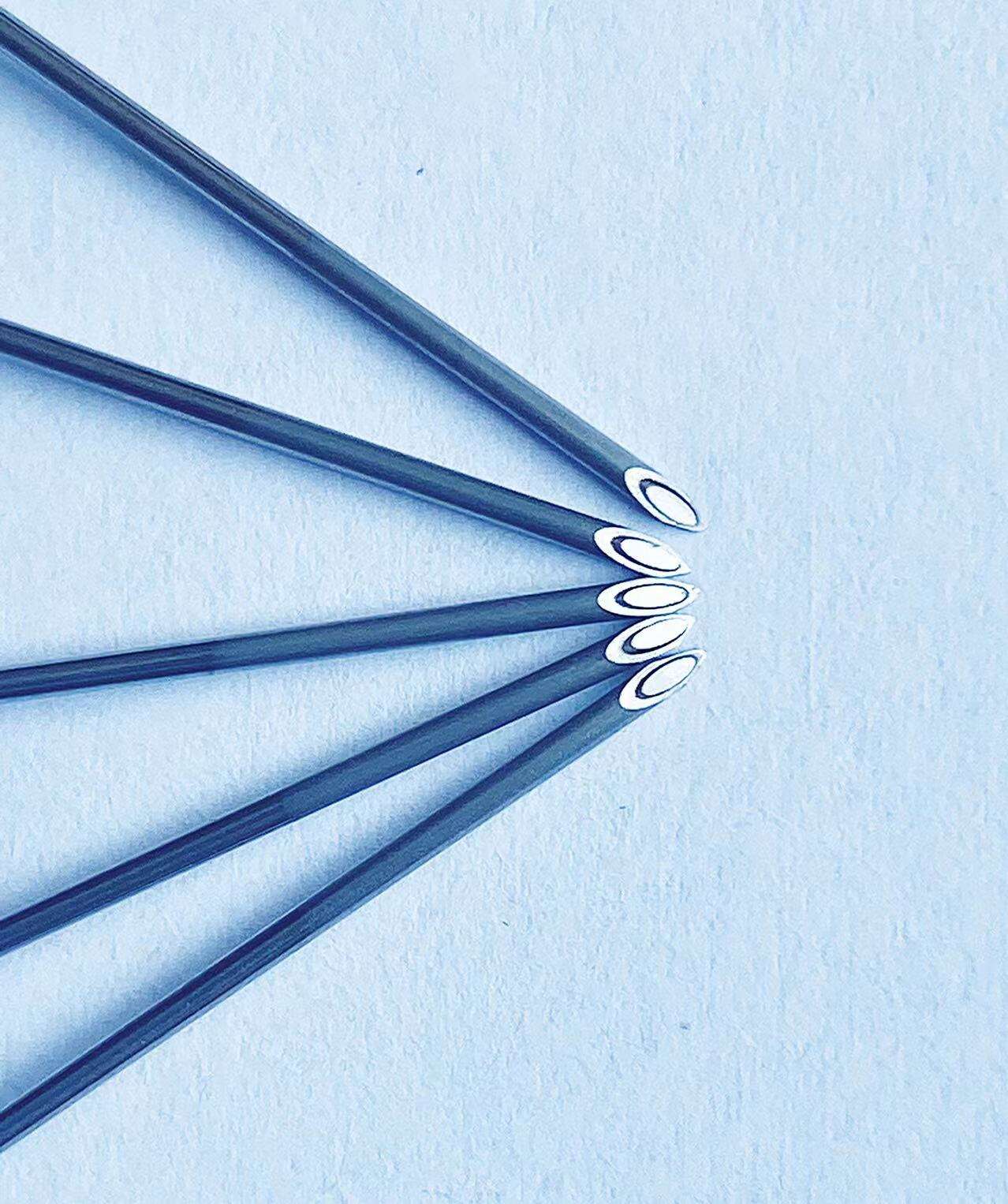

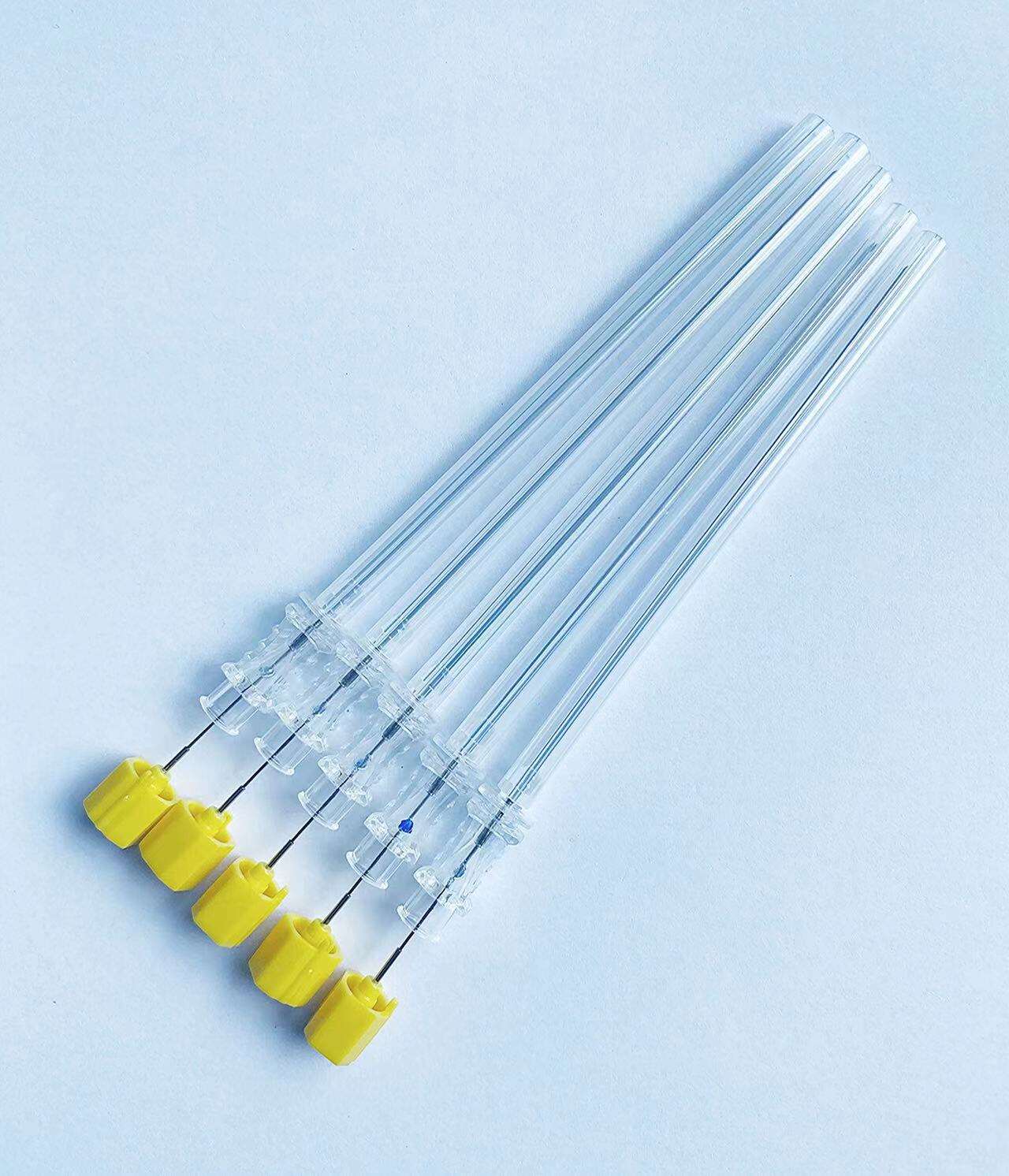

The disposable spinal needle incorporates state-of-the-art precision engineering that sets new standards for clinical performance and procedural success rates. Manufacturing processes utilize computer-controlled machinery that maintains tolerances measured in micrometers, ensuring consistent needle geometry across production batches. The ultra-sharp beveled tip design results from specialized grinding techniques that create an optimal cutting edge angle for effortless tissue penetration. This precision engineering translates directly into clinical benefits including reduced insertion force requirements, decreased patient discomfort, and improved procedural success rates. Healthcare professionals report enhanced tactile feedback during needle advancement, allowing for better anatomical landmark identification and more accurate placement. The needle shaft maintains perfect straightness throughout its length, preventing deflection during insertion that could compromise procedural accuracy. Quality control protocols include automated inspection systems that verify dimensional accuracy, surface finish quality, and tip sharpness for every disposable spinal needle produced. Advanced materials science contributes to the needle's exceptional performance characteristics through selection of premium grade stainless steel alloys that provide optimal strength and corrosion resistance. The removable stylet features precision machining that ensures perfect fit within the needle lumen, preventing tissue coring while maintaining smooth insertion characteristics. Surface treatments applied during manufacturing reduce friction coefficients, enabling smoother needle advancement through tissue planes. This engineering excellence extends to the needle hub design, which incorporates ergonomic features that enhance practitioner control and reduce hand fatigue during extended procedures. Color-coded hubs provide instant gauge identification, supporting procedural efficiency and reducing selection errors. The connection interface between needle and syringe utilizes standard Luer-lock threading that ensures secure attachment while maintaining low connection torque requirements.