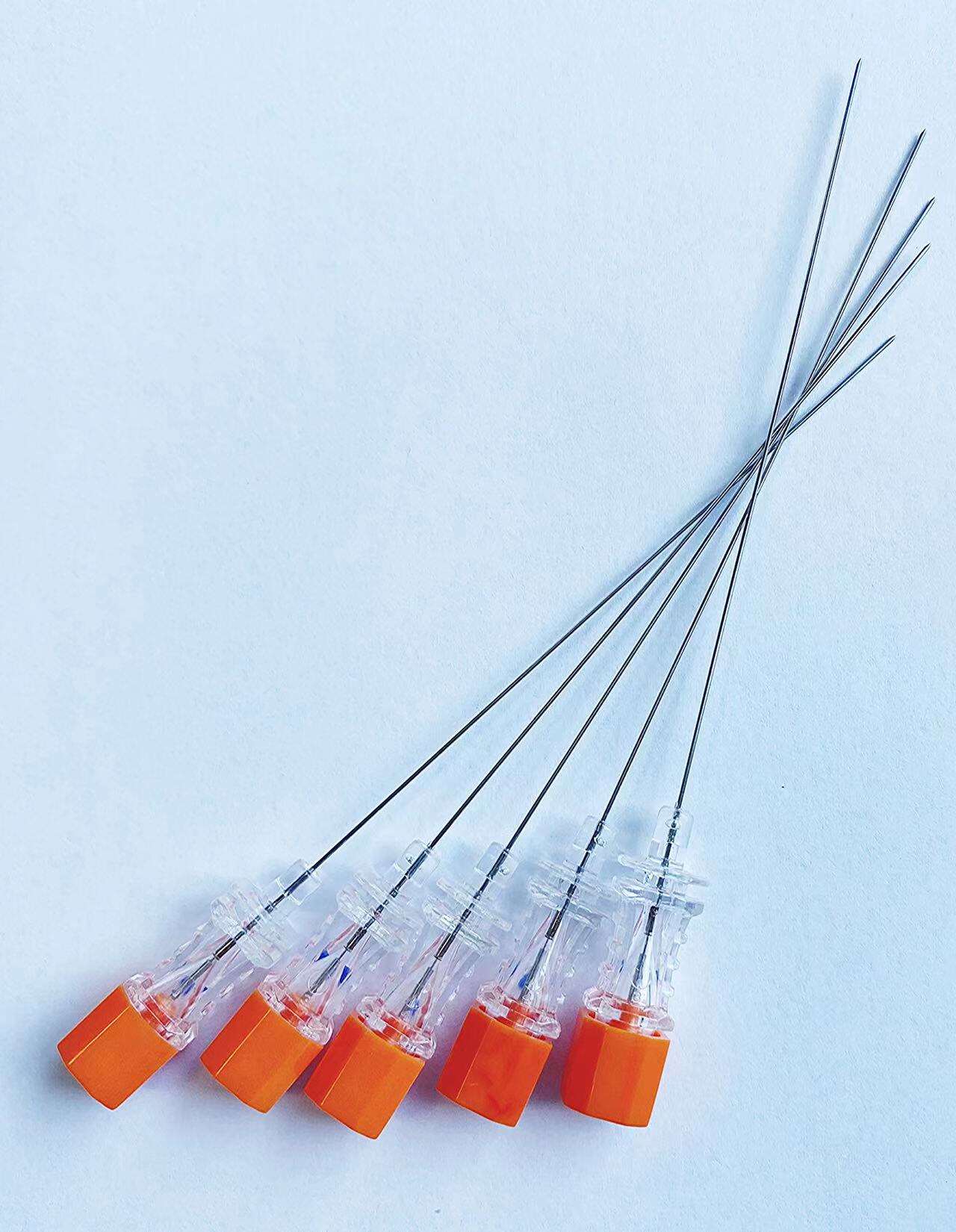

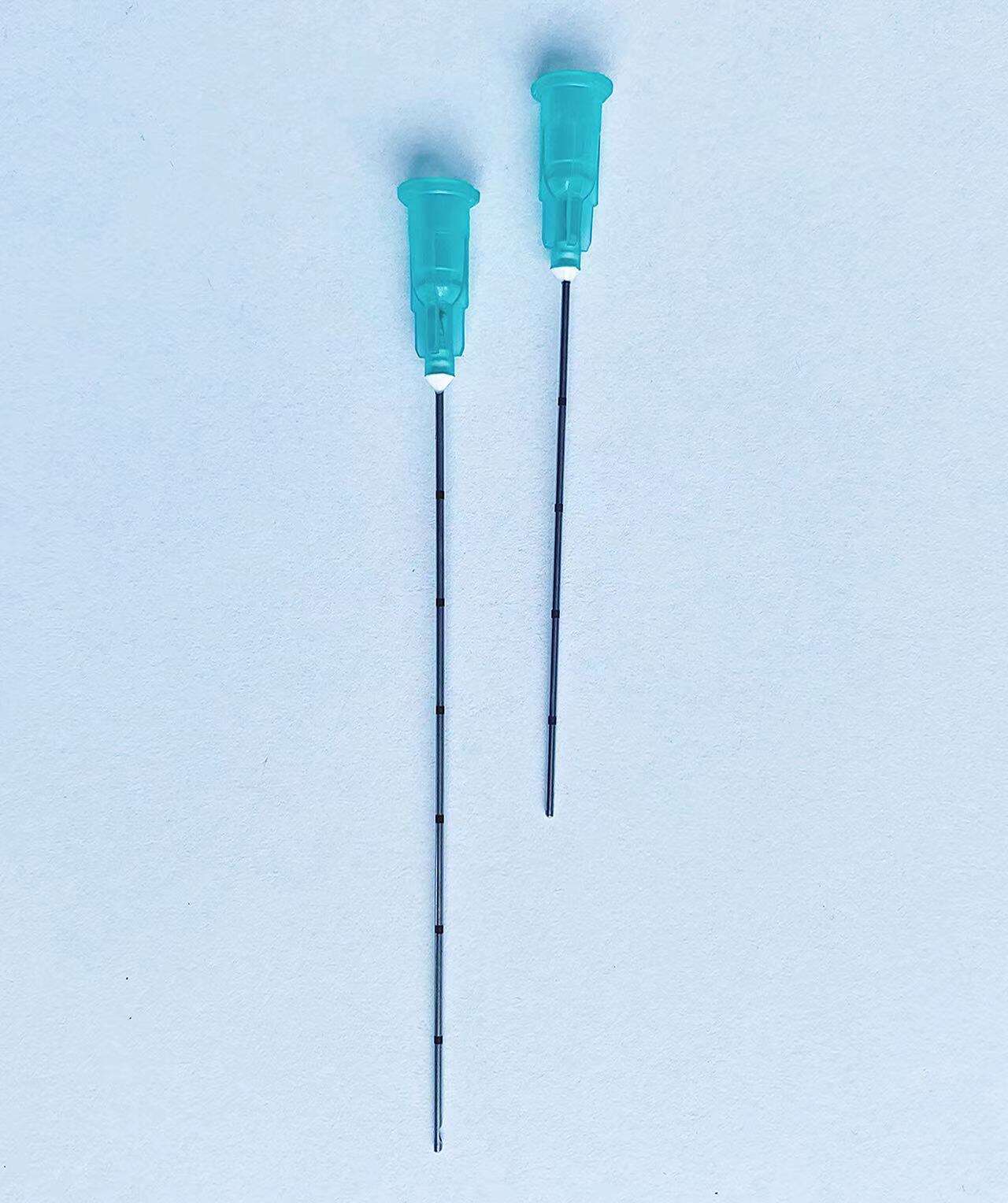

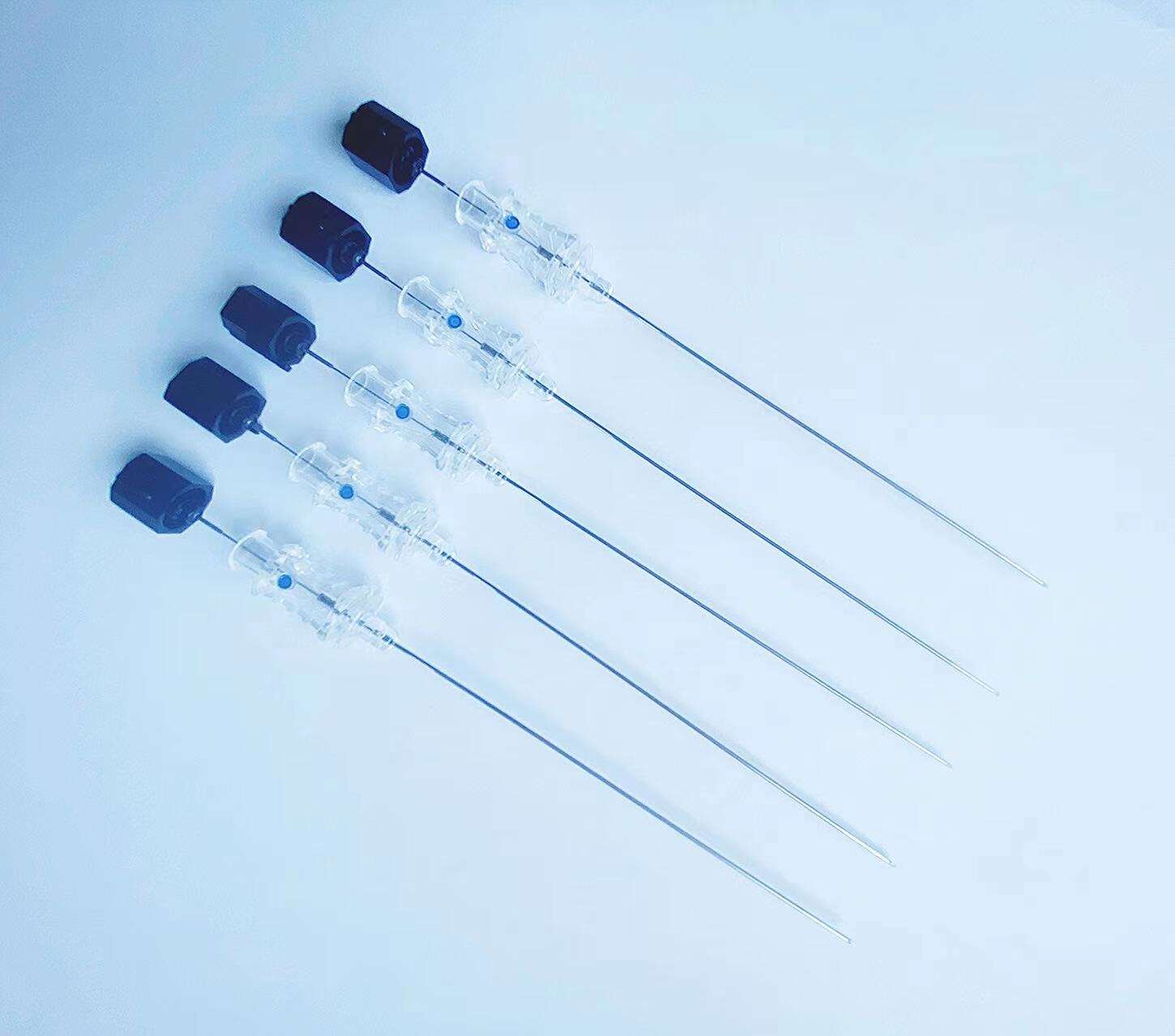

different spinal needles

Different spinal needles represent a critical component in modern medical procedures, serving as specialized instruments designed for accessing the spinal canal and cerebrospinal fluid. These medical devices come in various configurations, each engineered to meet specific procedural requirements and patient needs. The primary function of different spinal needles involves penetrating the ligamentum flavum and dura mater to reach the subarachnoid space, enabling healthcare professionals to perform lumbar punctures, spinal anesthesia, and diagnostic sampling procedures. The technological features of these instruments vary significantly across different types, with needle gauge sizes ranging from 18 to 27, each offering distinct penetration characteristics and fluid flow rates. Cutting-edge manufacturing techniques ensure that different spinal needles maintain optimal sharpness while minimizing tissue trauma during insertion. The beveled tip design represents a fundamental technological advancement, allowing for smoother tissue penetration and reduced patient discomfort. Many modern variations incorporate pencil-point tips, which separate tissue fibers rather than cutting them, significantly reducing post-procedural complications such as headaches. The applications for different spinal needles span across multiple medical specialties, including anesthesiology, neurology, and emergency medicine. In anesthesiology, these instruments facilitate epidural and spinal blocks for surgical procedures, providing effective pain management during operations. Neurologists utilize them for diagnostic lumbar punctures to analyze cerebrospinal fluid composition, helping diagnose conditions like meningitis, multiple sclerosis, and subarachnoid hemorrhage. Emergency medicine practitioners rely on different spinal needles for rapid diagnostic procedures and therapeutic interventions in critical care situations. The construction materials typically include high-grade stainless steel, ensuring durability and resistance to corrosion while maintaining the necessary flexibility for precise navigation through anatomical structures.