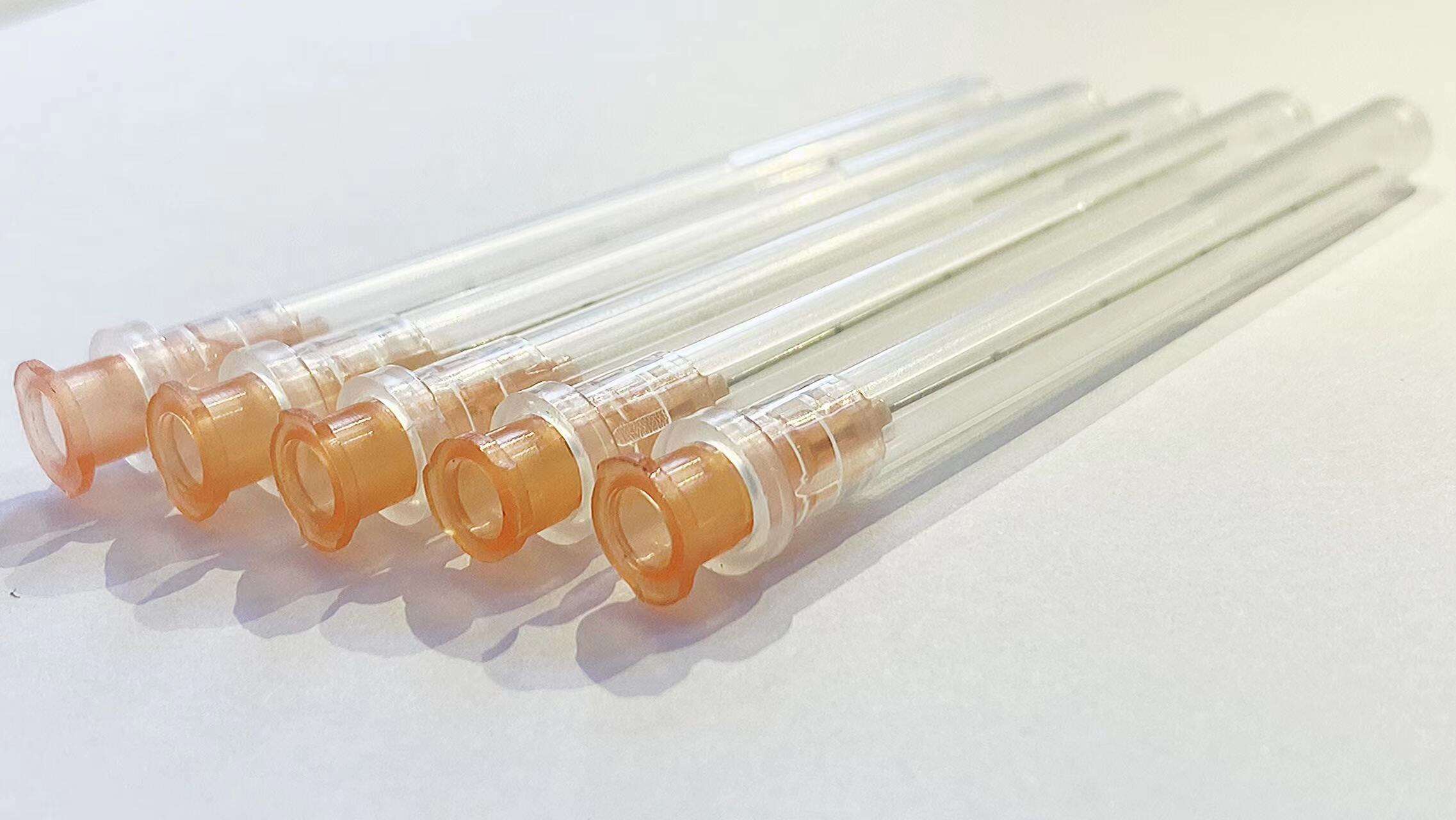

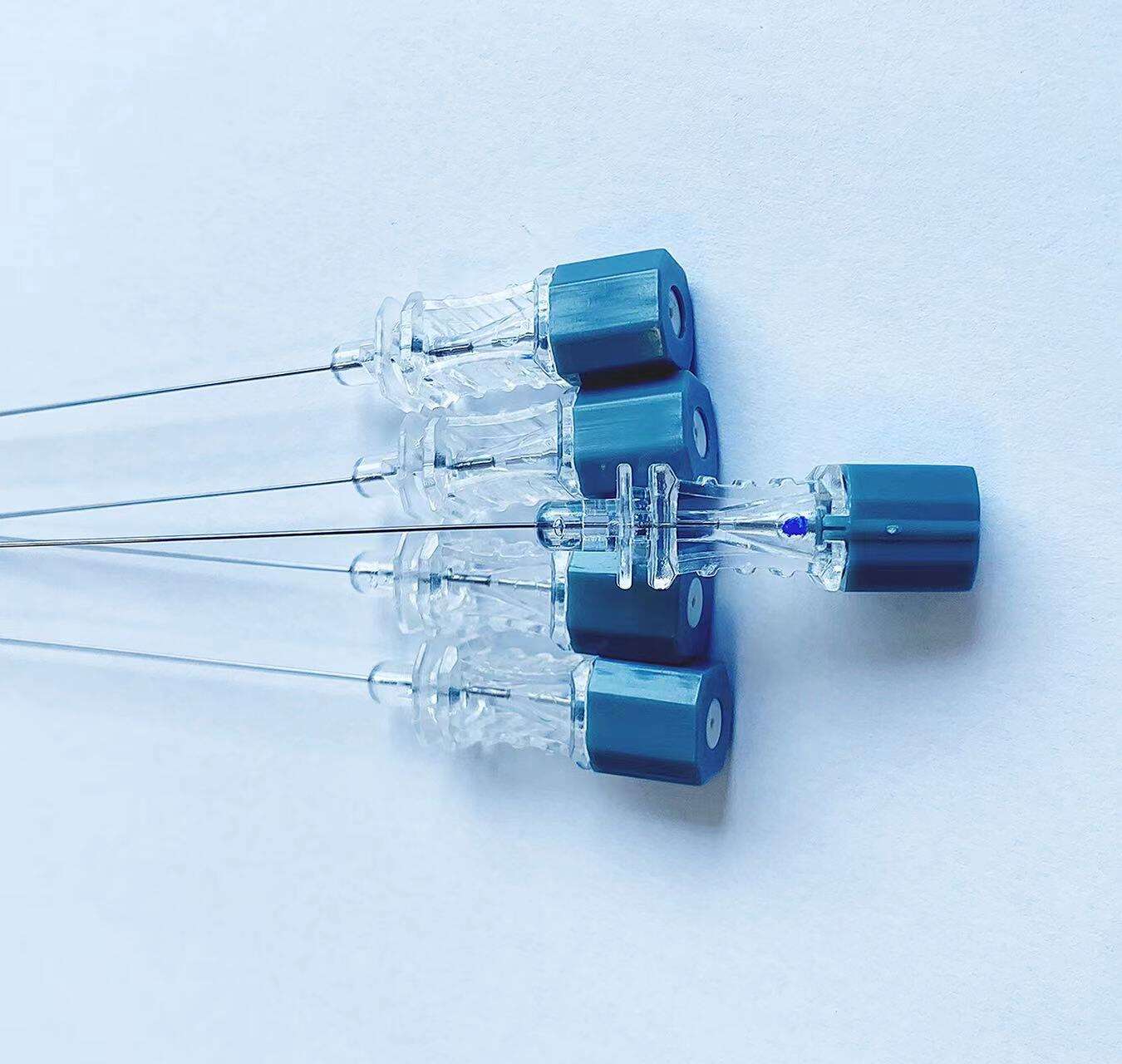

quincke tip needle made in china

The quincke tip needle made in china represents a significant advancement in medical injection technology, specifically designed for spinal anesthesia and lumbar puncture procedures. This specialized medical device features a distinctive pencil-point design that sets it apart from conventional cutting needles. The quincke tip needle made in china incorporates precision engineering and high-quality materials to deliver exceptional performance in clinical settings. The primary function of this needle involves creating access to the subarachnoid space while minimizing tissue trauma and reducing the risk of post-dural puncture headaches. The technological features of the quincke tip needle made in china include its sharp, beveled tip that provides smooth penetration through tissue layers. The needle's construction utilizes medical-grade stainless steel that ensures durability and maintains sharpness throughout the procedure. Advanced manufacturing processes employed in China result in consistent quality control and precise dimensional accuracy. The quincke tip needle made in china features a standardized hub design that ensures secure attachment to syringes and prevents accidental disconnection during procedures. The applications of this medical device extend across various clinical specialties, including anesthesiology, emergency medicine, and diagnostic procedures. Healthcare professionals utilize the quincke tip needle made in china for spinal anesthesia during surgical procedures, epidural injections for pain management, and cerebrospinal fluid sampling. The needle's design facilitates accurate placement and reduces the likelihood of multiple insertion attempts. Emergency departments rely on the quincke tip needle made in china for urgent procedures requiring quick and reliable access to the spinal canal. The manufacturing standards in China adhere to international medical device regulations, ensuring that each quincke tip needle meets stringent quality requirements. The production facilities utilize automated processes that enhance consistency and reduce manufacturing variability, resulting in reliable performance across different medical environments and patient populations.