Enhanced Precision and Accuracy for Optimal Treatment Outcomes

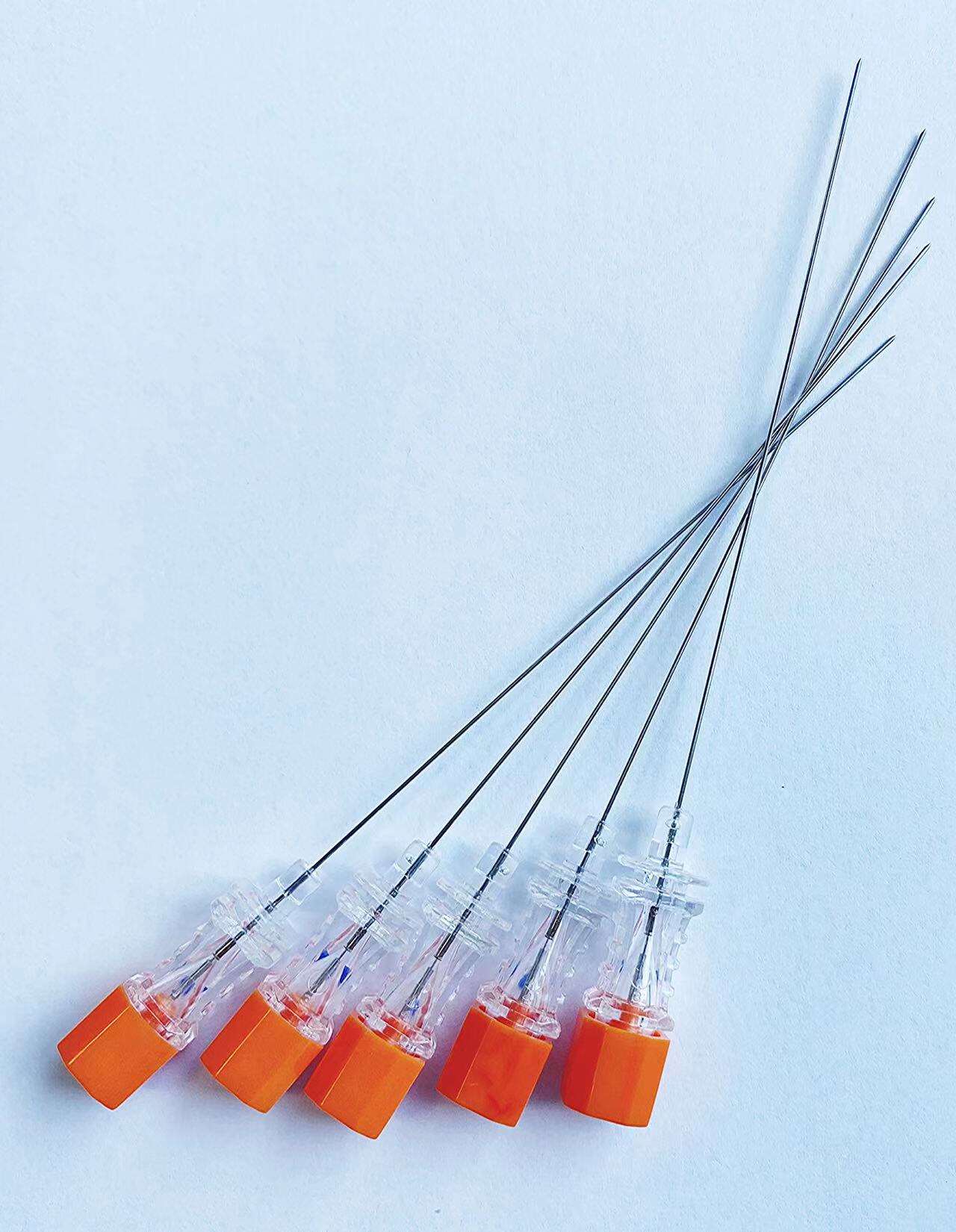

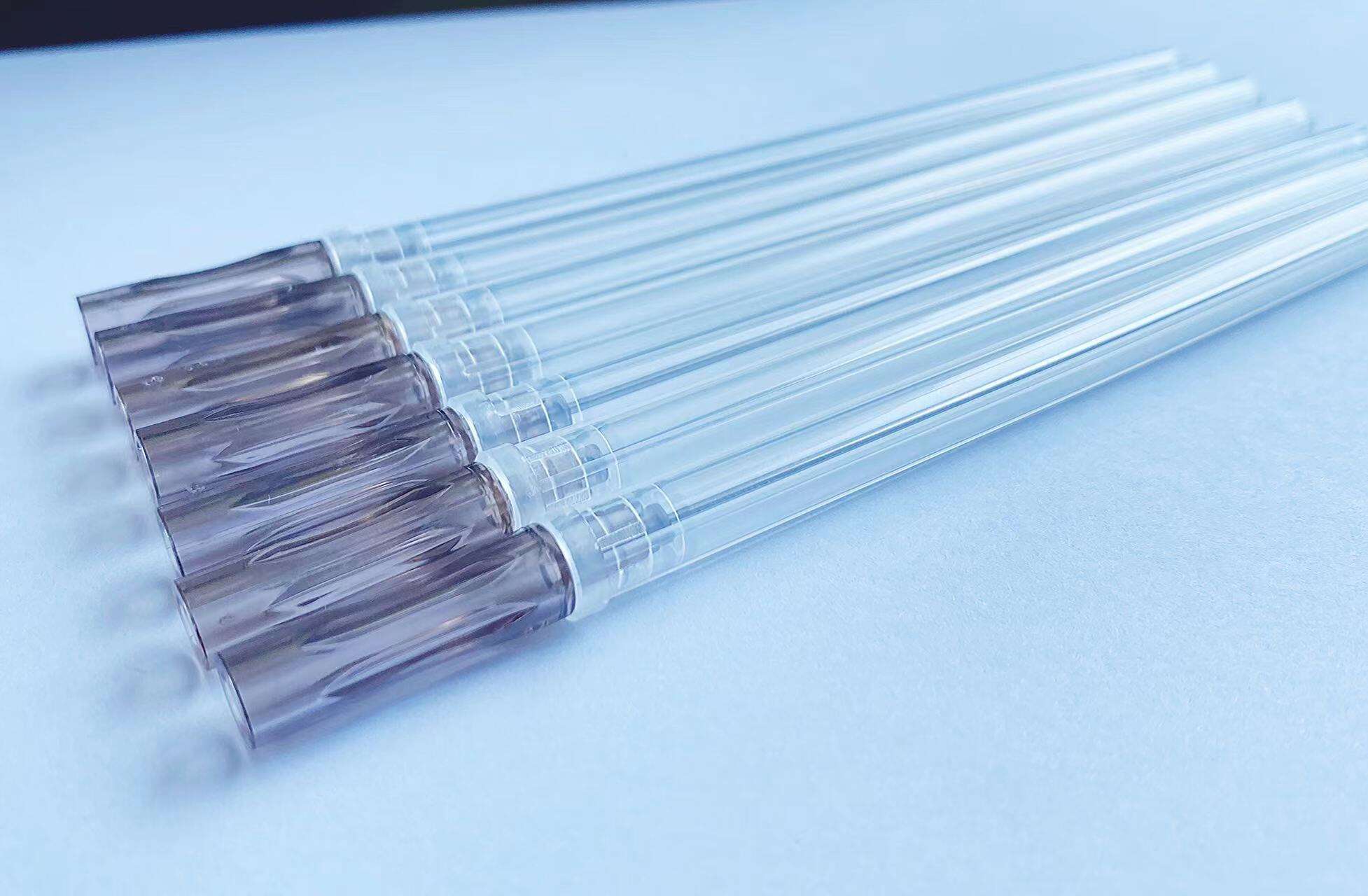

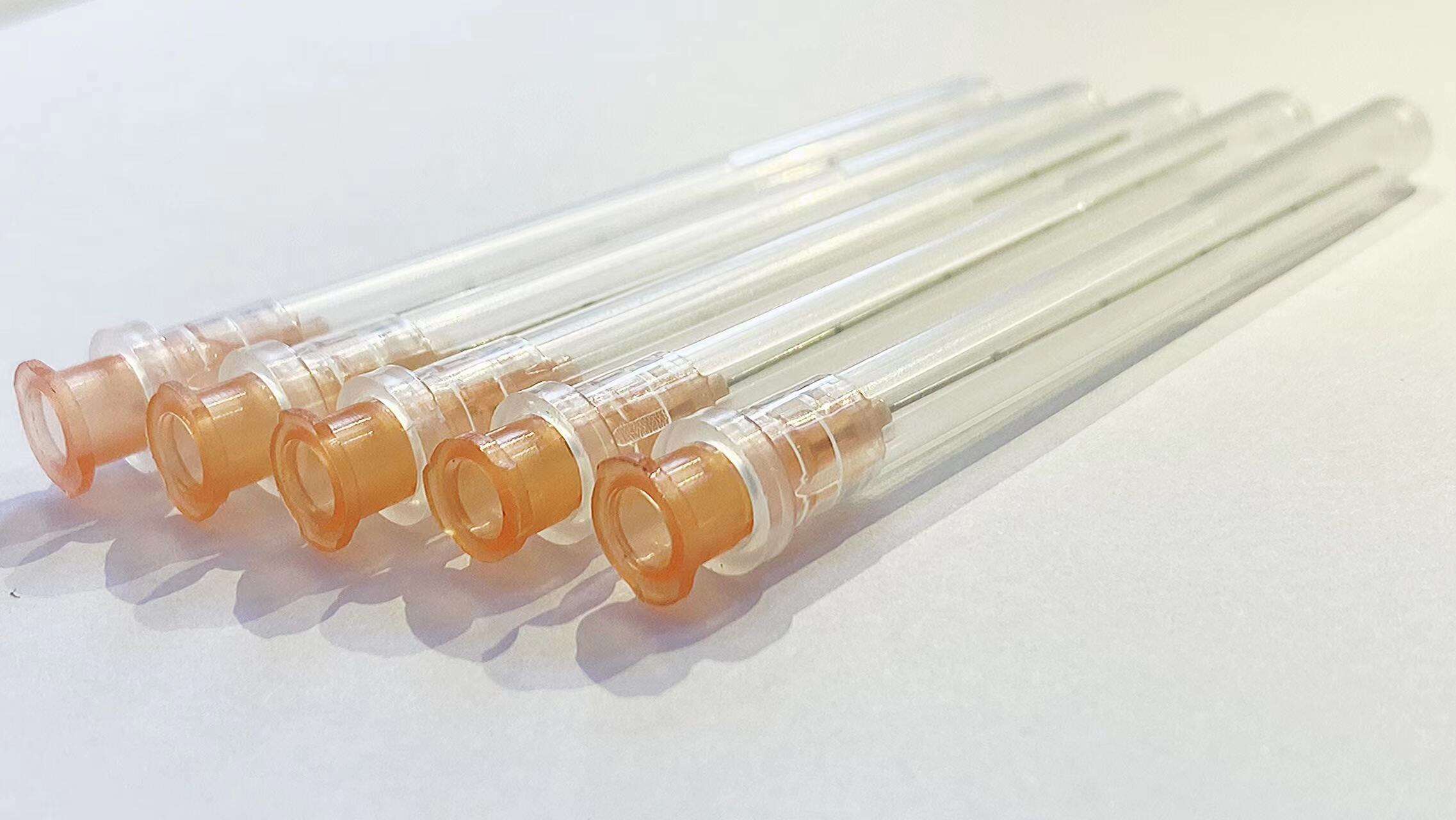

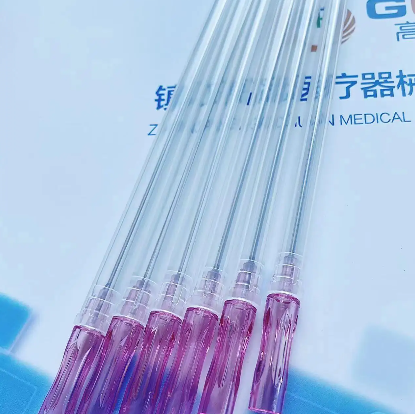

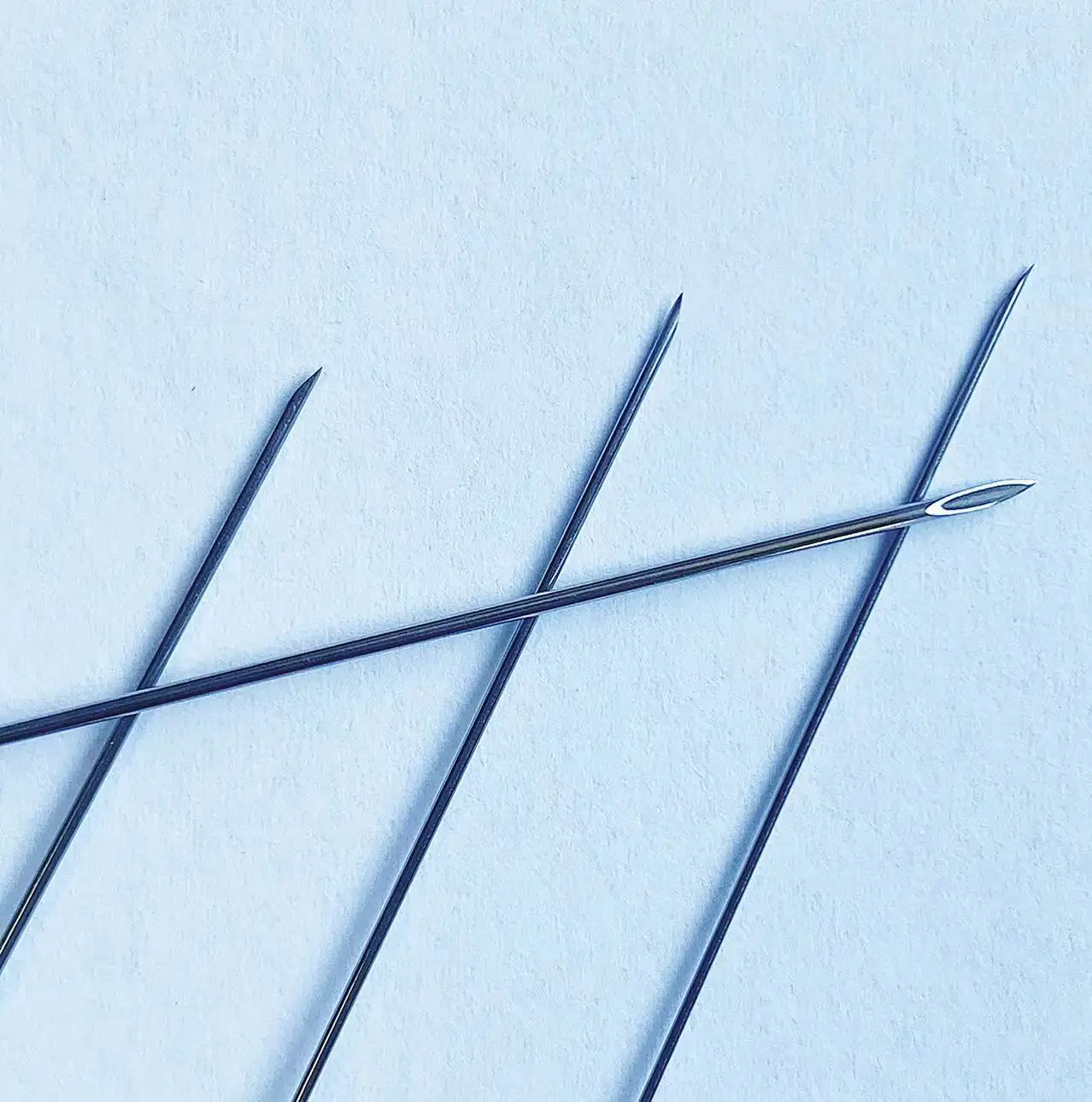

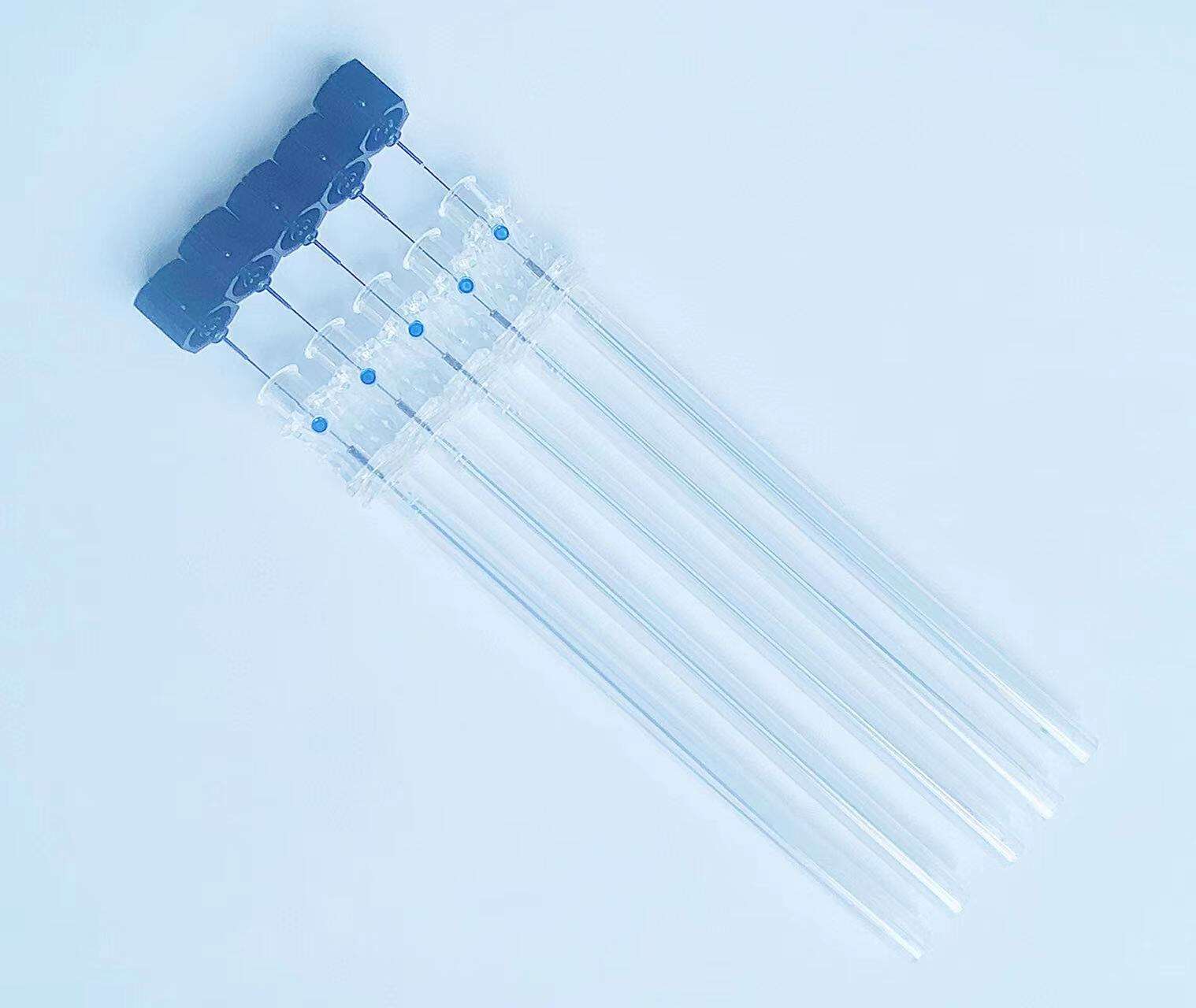

The pencil tip needle delivers exceptional precision and accuracy that significantly improves injection outcomes across diverse medical applications, representing a technological leap forward from conventional needle designs. The unique tapered geometry provides superior control during insertion, allowing healthcare professionals to navigate tissue layers with unprecedented accuracy and reach specific anatomical targets with confidence. This enhanced precision stems from the needle's ability to maintain directional stability throughout the insertion process, reducing deflection and deviation from intended injection paths. Medical practitioners report improved tactile feedback when using pencil tip needles, enabling better assessment of tissue resistance and depth progression during injections. The needle's design facilitates more controlled medication delivery, ensuring therapeutic agents reach their intended destinations without unintended dispersion into surrounding tissues. This targeted delivery approach maximizes treatment efficacy while minimizing potential side effects associated with medication placement errors. Intramuscular injections benefit particularly from the pencil tip needle's precision capabilities, as accurate placement within muscle tissue ensures optimal drug absorption and therapeutic response. Subcutaneous administrations similarly demonstrate improved outcomes, with medications deposited at appropriate depths for sustained release and consistent bioavailability. The needle's stability during insertion reduces the likelihood of tissue damage that might compromise injection site integrity or interfere with healing processes. Healthcare facilities utilizing pencil tip needles report decreased rates of injection complications, including reduced instances of bleeding, bruising, and post-injection site reactions. Quality assurance protocols ensure each pencil tip needle meets stringent manufacturing tolerances, guaranteeing consistent performance characteristics across all units. The precision benefits extend to diagnostic procedures requiring accurate sample collection or contrast agent administration, where precise needle placement directly impacts procedural success rates. Training programs emphasize the enhanced control capabilities of pencil tip needles, helping healthcare providers maximize the technology's precision advantages. Cost-effectiveness emerges from reduced medication waste due to more accurate delivery, fewer repeat procedures resulting from initial placement errors, and decreased complication rates requiring additional interventions. The precision improvements contribute to better patient outcomes, reduced treatment times, and enhanced healthcare provider confidence during challenging injection procedures.