pencil point needle manufacturer

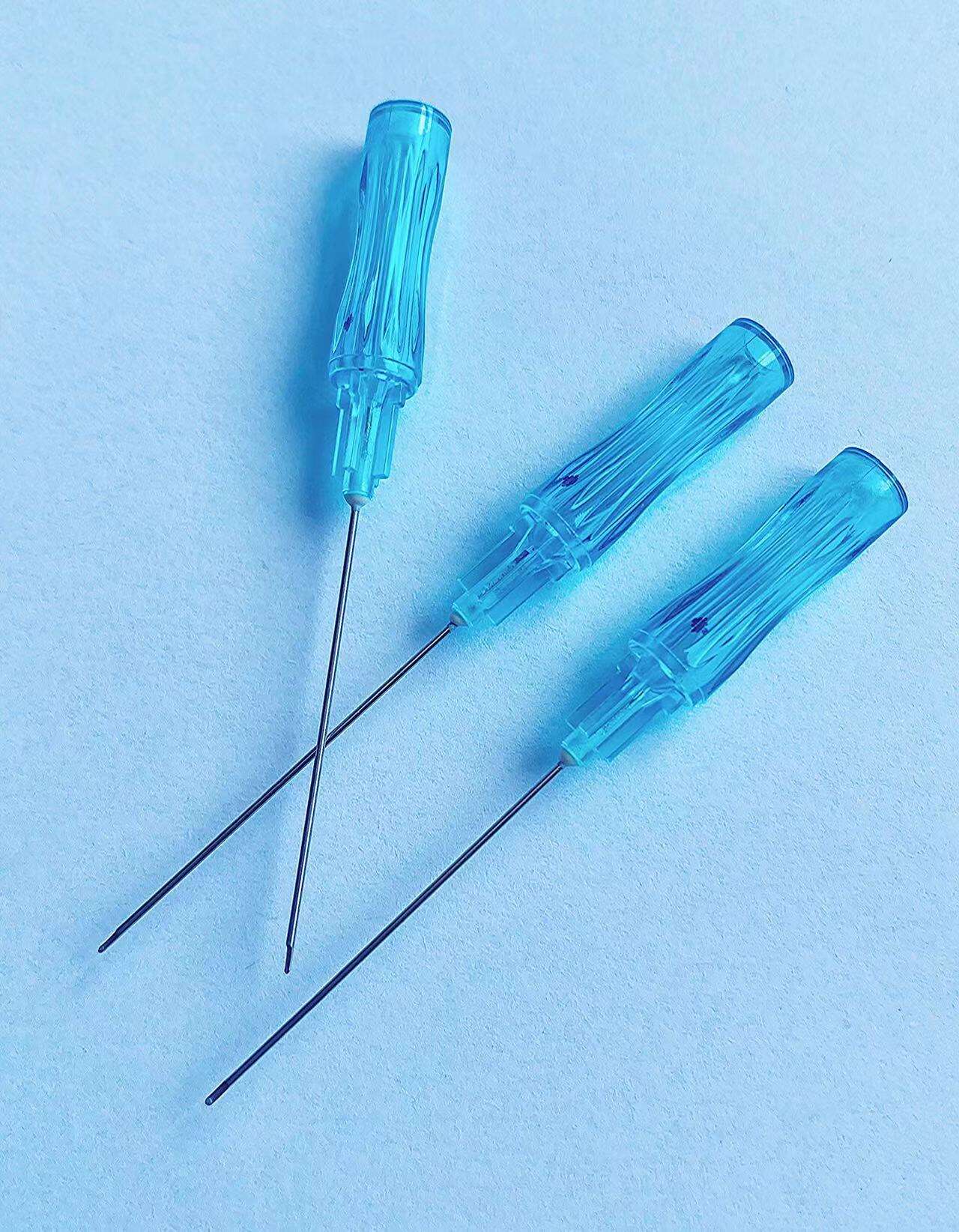

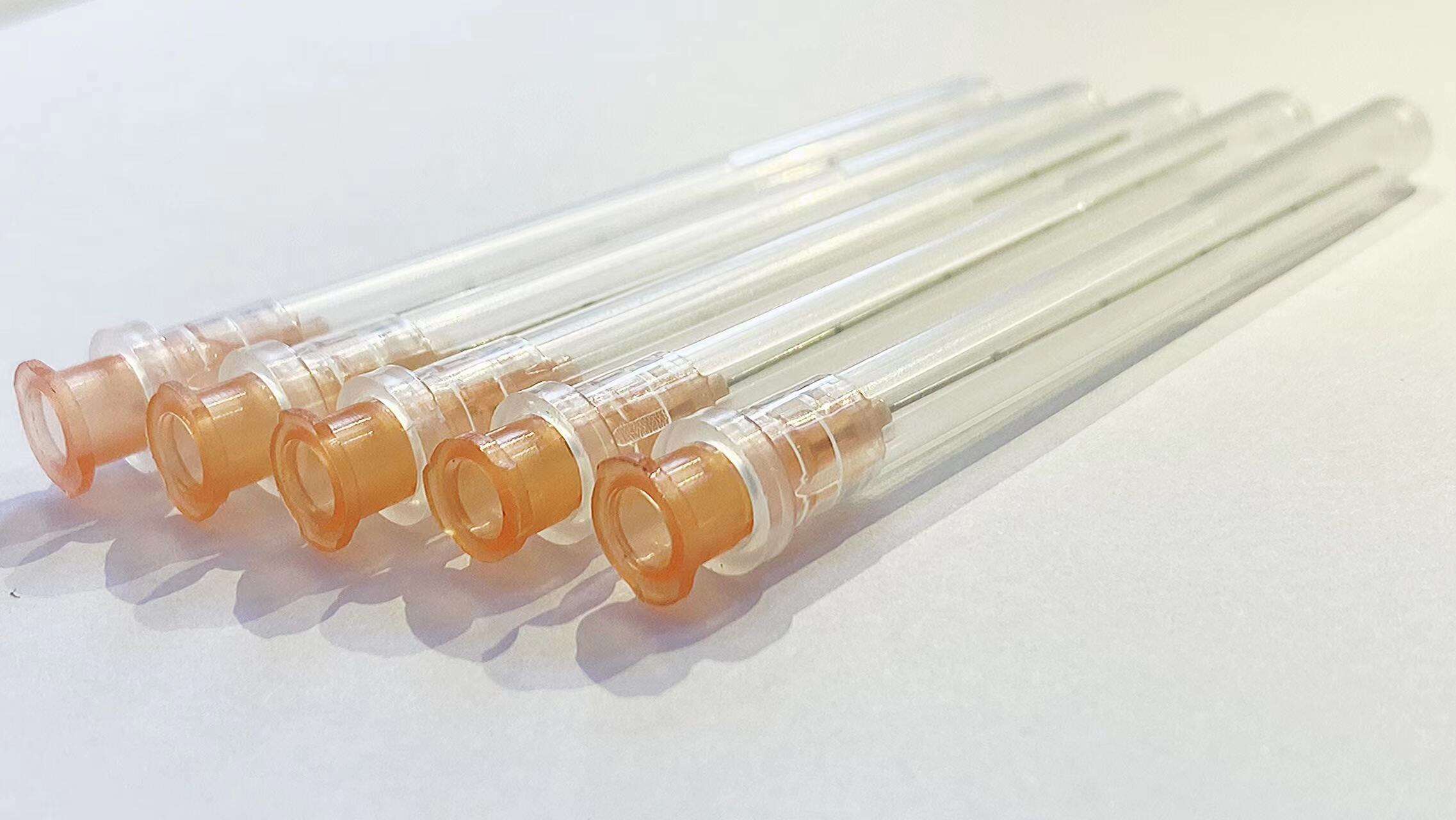

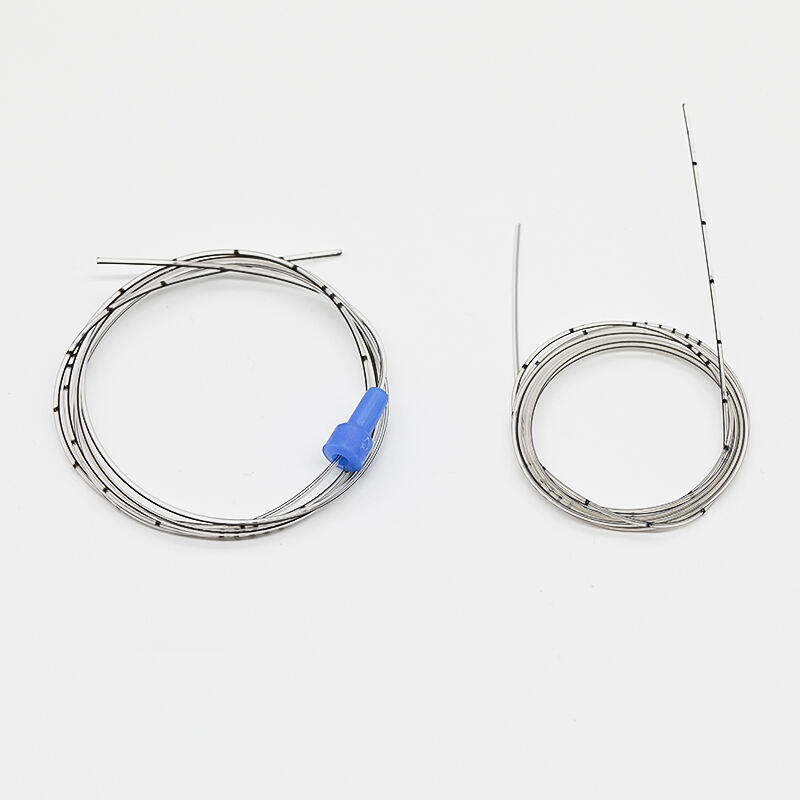

A pencil point needle manufacturer represents a specialized medical device company that designs and produces precision surgical instruments essential for minimally invasive procedures. These manufacturers focus on creating needles with distinctively shaped tips that resemble pencil points, offering superior penetration capabilities and enhanced patient safety during various medical applications. The pencil point needle manufacturer employs advanced engineering techniques to develop products that meet stringent medical standards while delivering exceptional performance in clinical settings. The primary function of a pencil point needle manufacturer involves manufacturing needles specifically designed for spinal anesthesia, epidural procedures, and other neuraxial blocks. These needles feature a conical, non-cutting tip that separates tissue fibers rather than cutting through them, significantly reducing the risk of cerebrospinal fluid leakage and post-procedural complications. The technological features incorporated by a pencil point needle manufacturer include precision machining processes, specialized steel alloys, and rigorous quality control systems that ensure consistent product reliability. Manufacturing facilities utilize state-of-the-art equipment to achieve microscopic tolerances in needle dimensions, ensuring optimal performance across different medical procedures. The applications for products from a pencil point needle manufacturer extend across multiple medical specialties, including anesthesiology, pain management, and neurological interventions. These needles prove particularly valuable in obstetric anesthesia, where patient safety and comfort remain paramount concerns. Additionally, the pencil point needle manufacturer serves orthopedic surgeons, emergency medicine practitioners, and specialized pain clinics that require reliable, high-performance instruments for their procedures. Modern pencil point needle manufacturer operations incorporate advanced sterilization processes, biocompatibility testing, and comprehensive documentation systems to meet international regulatory requirements. The manufacturing process involves multiple quality checkpoints, ensuring each needle meets exacting standards for sharpness, durability, and safety before reaching healthcare providers worldwide.