epidural needle made in china

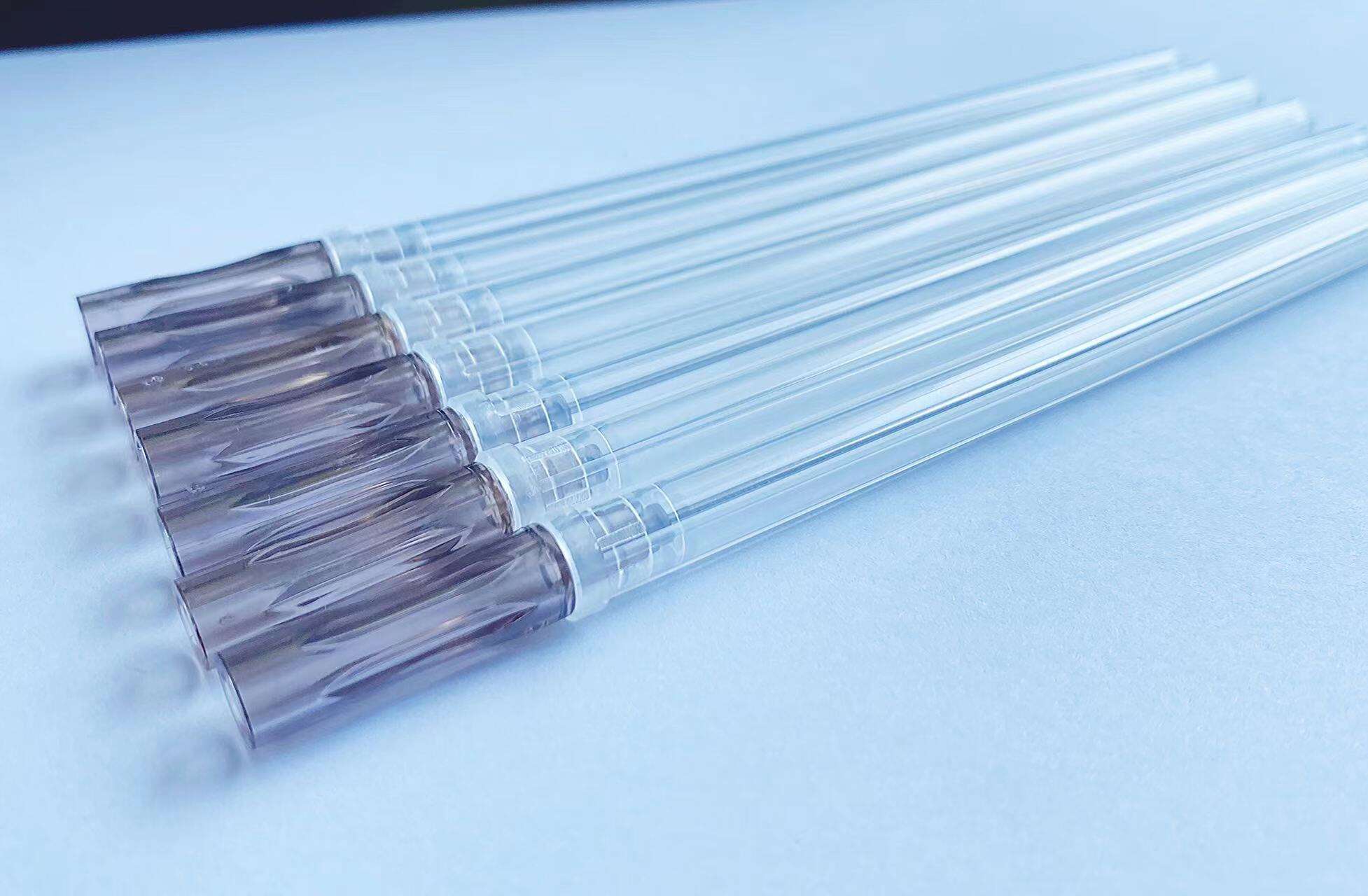

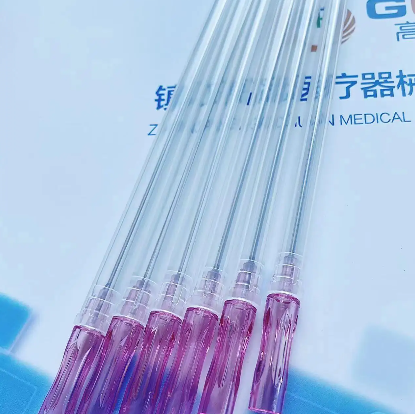

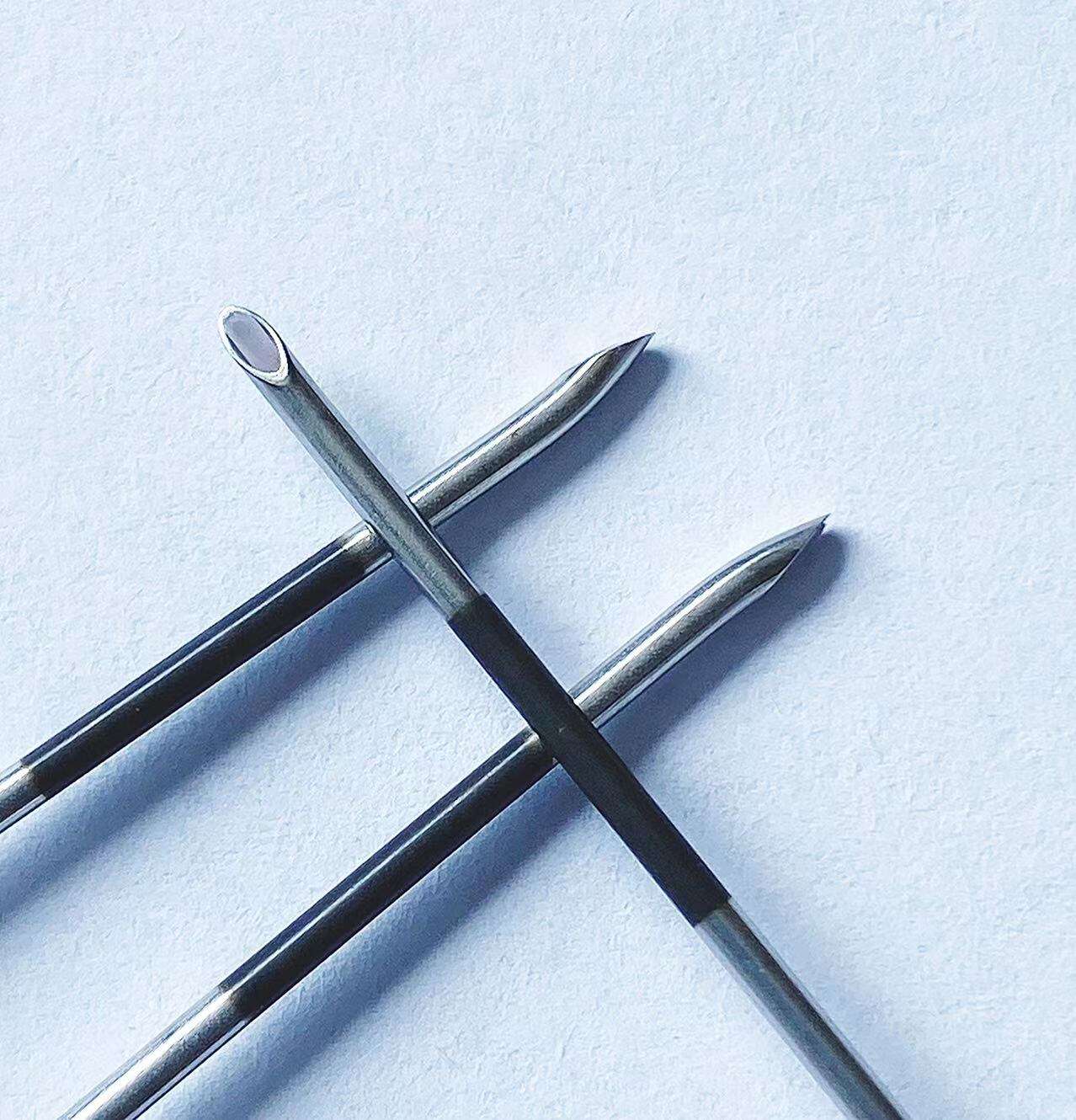

The epidural needle made in China represents a significant advancement in medical technology, specifically designed for precise spinal anesthesia and pain management procedures. These sophisticated medical instruments serve as essential tools for healthcare professionals performing epidural injections, combining traditional manufacturing expertise with modern technological innovations. The primary function of an epidural needle made in China involves creating accurate access points to the epidural space, enabling effective delivery of anesthetic agents or therapeutic medications. Chinese manufacturers have developed these needles using advanced metallurgy techniques, ensuring optimal sharpness retention and durability throughout multiple uses. The technological features include precision-engineered beveled tips that minimize tissue trauma during insertion, while maintaining excellent tactile feedback for practitioners. These epidural needles incorporate ergonomic handle designs that provide superior grip control and reduce hand fatigue during lengthy procedures. The manufacturing process employs state-of-the-art quality control systems, ensuring consistent product performance across production batches. Chinese-produced epidural needles feature specialized hub configurations that facilitate secure connections with injection systems, preventing medication leakage or disconnection during critical moments. The applications extend beyond standard epidural anesthesia to include chronic pain management, labor analgesia, and postoperative pain control protocols. Medical facilities worldwide increasingly rely on epidural needles made in China due to their cost-effectiveness and reliable performance standards. These instruments undergo rigorous testing procedures to meet international medical device regulations, ensuring patient safety and procedural success rates. The versatility of epidural needles made in China makes them suitable for various patient populations, from pediatric to geriatric cases, with different gauge options available to match specific clinical requirements.