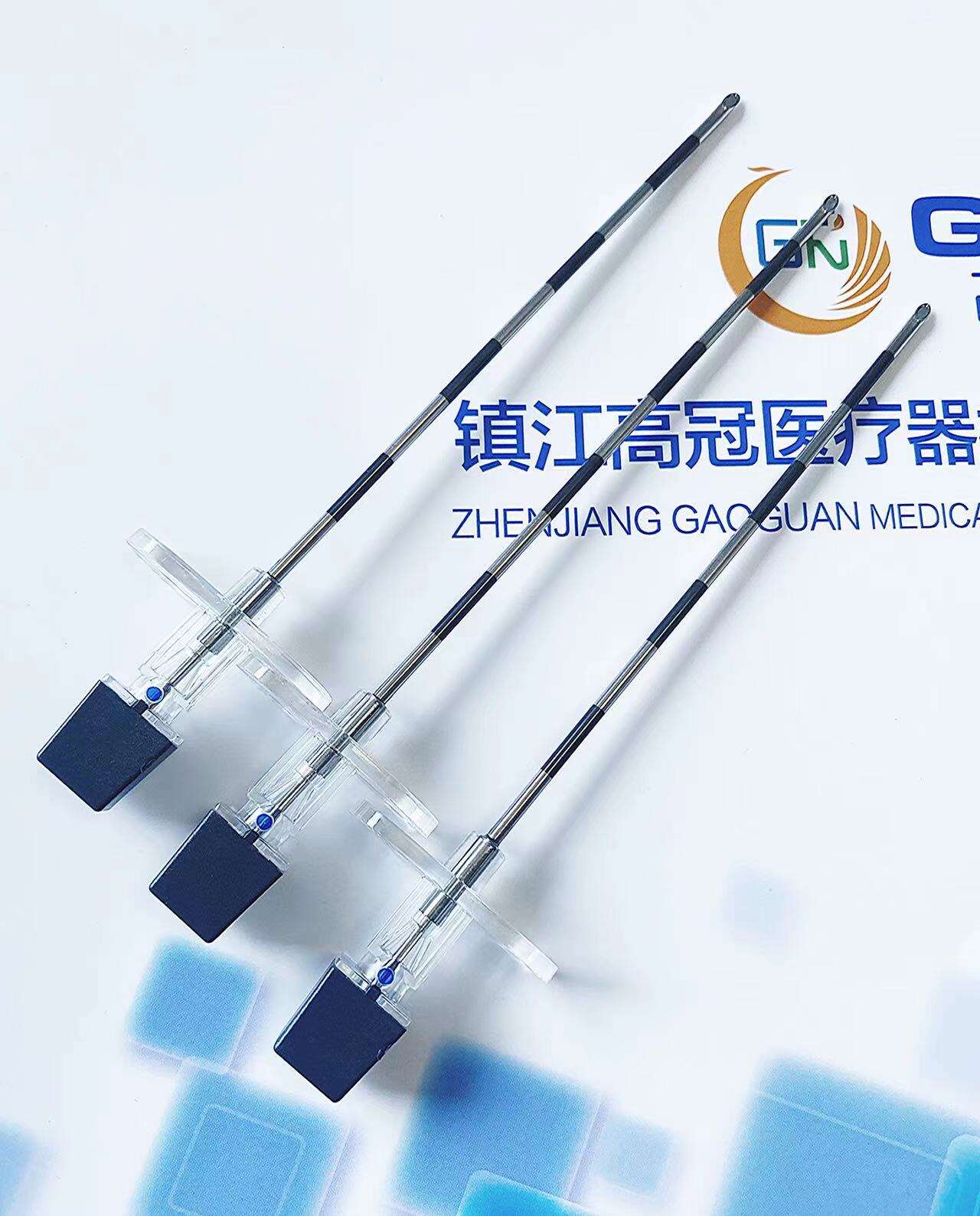

Advanced Material Innovation for Unmatched Durability

The new epidural needle represents a breakthrough in medical device material science through the integration of advanced alloy compositions and surface treatment technologies that deliver unprecedented durability while maintaining optimal biocompatibility standards. Premium medical-grade stainless steel undergoes specialized heat treatment processes that enhance molecular structure integrity, resulting in needles that maintain their geometric precision and sharpness characteristics throughout extended clinical use. Advanced metallurgical techniques create material properties that resist bending, flexing, and tip deformation under the mechanical stresses encountered during challenging epidural procedures, ensuring consistent performance in demanding clinical situations. The new epidural needle's material innovation includes proprietary surface coating technologies that provide enhanced corrosion resistance, extended sterility maintenance, and improved tissue interaction characteristics that benefit both practitioners and patients. Quality assurance protocols verify that each needle meets or exceeds international standards for medical device materials, including comprehensive biocompatibility testing that ensures patient safety across diverse population groups and extended exposure periods. Material durability enhancements enable the new epidural needle to maintain its critical dimensional specifications throughout the sterilization, storage, and clinical use cycle, eliminating performance degradation that can occur with inferior material compositions. Advanced manufacturing processes optimize material grain structure orientation, creating needles with superior mechanical properties that resist fracture and maintain structural integrity under extreme procedural conditions. The material innovation extends to packaging and storage considerations, with protective systems designed to preserve needle quality during transportation and inventory management, ensuring optimal performance characteristics are maintained until the moment of clinical use. Clinical validation studies demonstrate that the advanced materials maintain their performance characteristics across temperature variations, humidity changes, and extended storage periods, providing healthcare facilities with reliable inventory management capabilities and consistent clinical results. Environmental considerations incorporate sustainable material sourcing and recyclability features that align with modern healthcare facility sustainability initiatives while maintaining uncompromised performance standards. The durability advantages translate into cost-effectiveness through reduced waste generation, improved inventory turnover rates, and enhanced practitioner confidence in needle reliability during critical procedural moments.