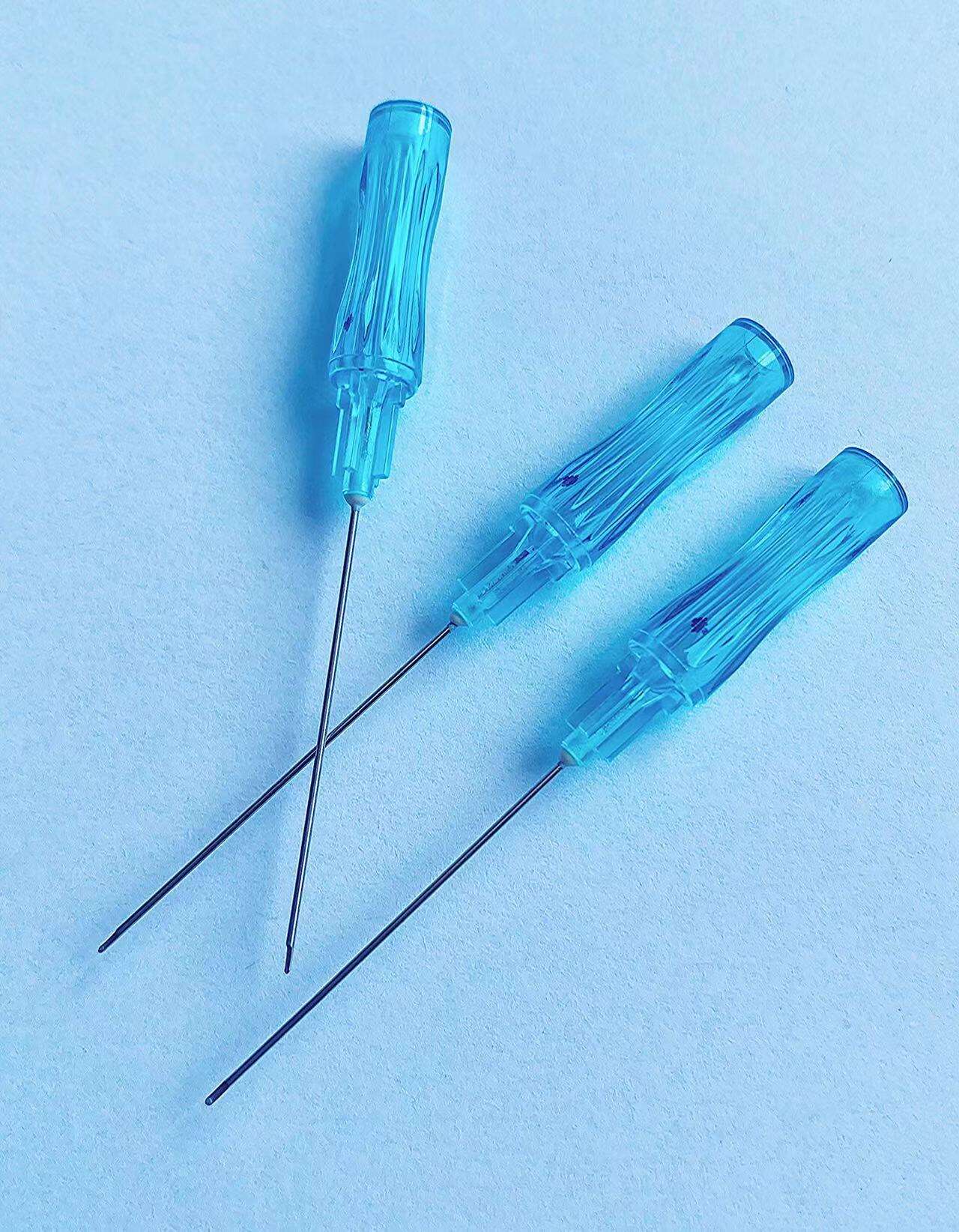

good embedding needle

The good embedding needle represents a revolutionary advancement in medical device technology, specifically engineered for precise tissue penetration and material insertion procedures. This sophisticated instrument combines cutting-edge metallurgy with ergonomic design principles to deliver exceptional performance across diverse clinical applications. The good embedding needle features a ultra-sharp beveled tip constructed from premium-grade stainless steel, ensuring consistent penetration through various tissue types while minimizing patient discomfort and trauma. Its hollow-core design facilitates smooth material flow, making it ideal for procedures requiring accurate placement of therapeutic substances, biomaterials, or monitoring devices. The needle's surface undergoes specialized treatment processes that enhance biocompatibility and reduce friction during insertion. Advanced manufacturing techniques ensure dimensional accuracy within micrometer tolerances, guaranteeing reliable performance in critical medical procedures. The good embedding needle incorporates color-coded hub systems for easy gauge identification, streamlining workflow efficiency in busy clinical environments. Its universal connection compatibility allows seamless integration with standard syringes and delivery systems. The needle's reinforced construction prevents bending or breaking under normal operating conditions, ensuring procedural safety and reducing replacement costs. Quality control measures include rigorous testing protocols that verify sterility, sharpness retention, and structural integrity. The good embedding needle meets international medical device standards and regulatory requirements, providing healthcare professionals with confidence in its reliability and safety profile. Its versatile design accommodates various embedding procedures, from subcutaneous implantations to deeper tissue applications, making it an essential tool for modern medical practice.