Advanced Precision Engineering for Superior Clinical Performance

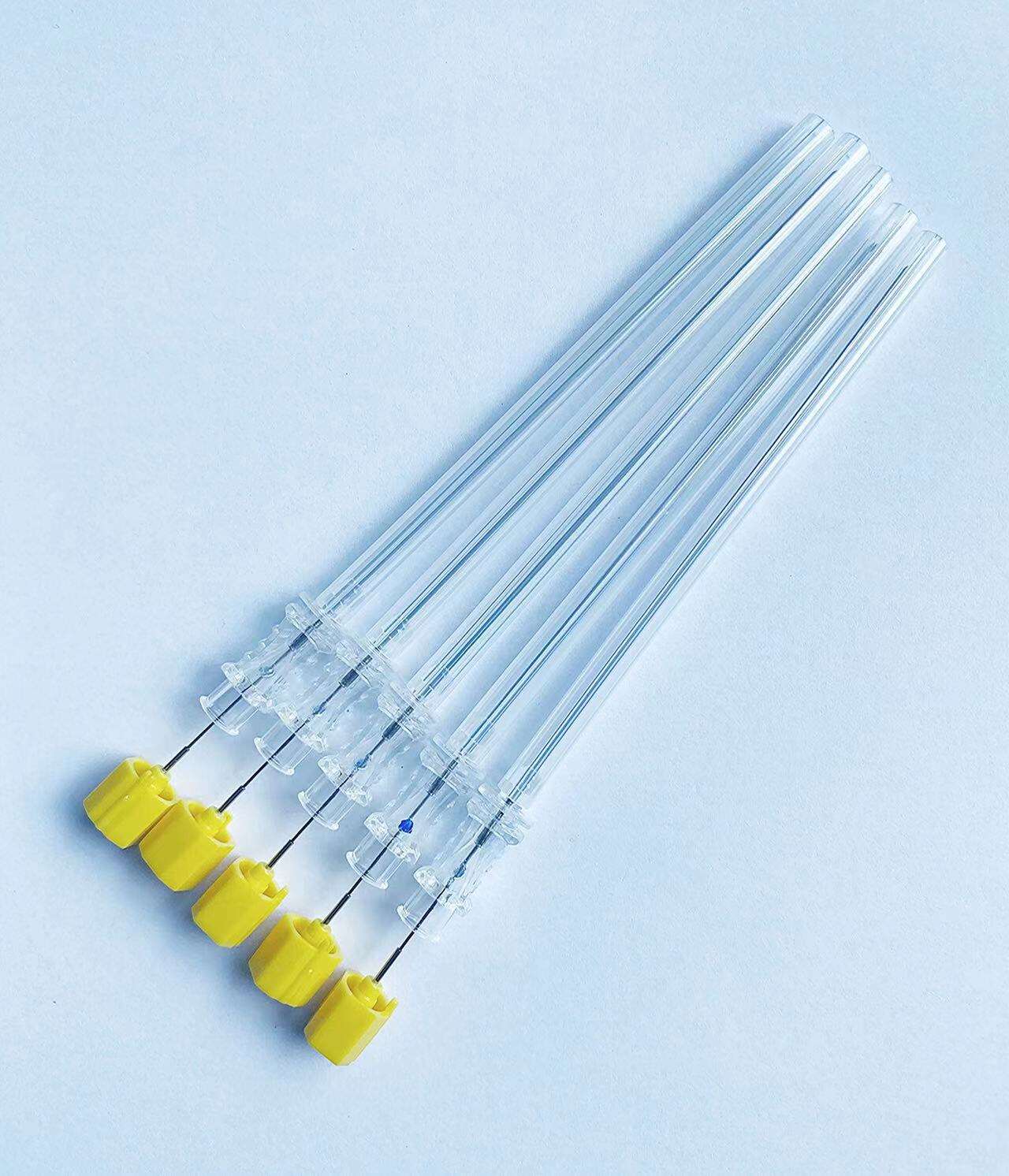

The orange spinal needle incorporates cutting-edge precision engineering that sets new standards for clinical performance in spinal access procedures. The manufacturing process utilizes state-of-the-art technology to create needle tips with microscopic precision, ensuring optimal sharpness retention and consistent penetration characteristics. Each orange spinal needle undergoes rigorous quality testing to verify tip geometry, shaft straightness, and hub attachment integrity before reaching clinical environments. The precision-ground bevel design creates an optimal angle that facilitates smooth tissue entry while minimizing resistance and patient discomfort. Advanced metallurgy techniques produce needle shafts with superior strength-to-flexibility ratios, preventing bending or breakage during challenging procedures. The engineering team behind the orange spinal needle continuously refines manufacturing processes based on clinical feedback and technological advancements. Quality control protocols include dimensional verification, surface finish analysis, and sterility validation to ensure each needle meets exacting specifications. The precision engineering extends to the hub design, which features carefully calculated wall thickness and internal geometry for optimal fluid flow dynamics. Manufacturing tolerances maintained during production result in consistent needle performance across different gauge sizes and lengths. The orange spinal needle's engineering excellence translates directly into improved procedural outcomes, reduced complication rates, and enhanced patient safety. Clinical studies demonstrate that precision-engineered needles like the orange spinal needle significantly improve first-attempt success rates during spinal procedures. The engineering team collaborates with medical professionals to incorporate real-world feedback into continuous product improvements. Advanced surface treatments applied during manufacturing reduce friction coefficients and enhance biocompatibility. The precision engineering approach ensures that each orange spinal needle delivers reliable performance regardless of patient anatomy variations or procedural complexity.