Comprehensive Size Range for Optimal Patient Care

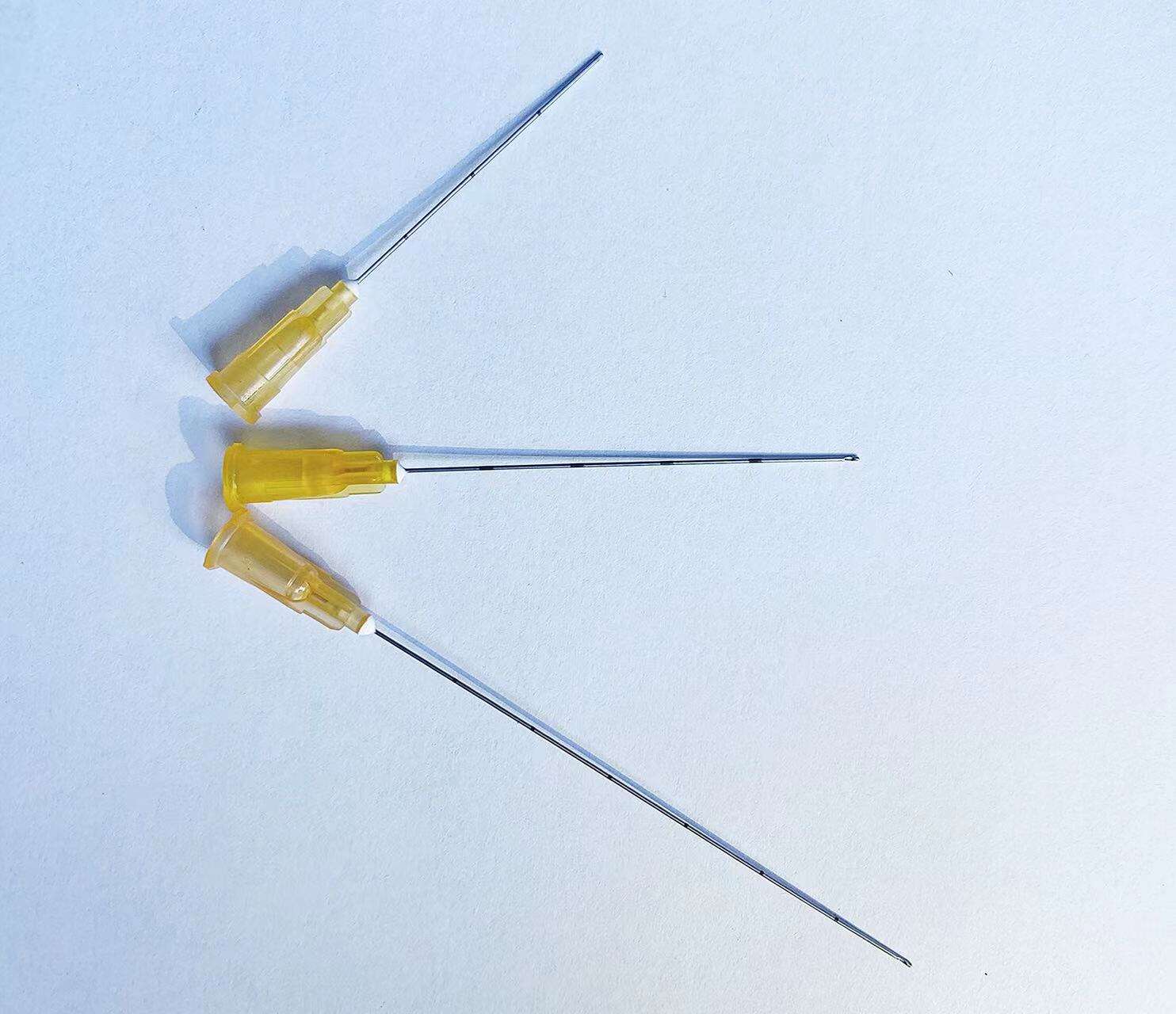

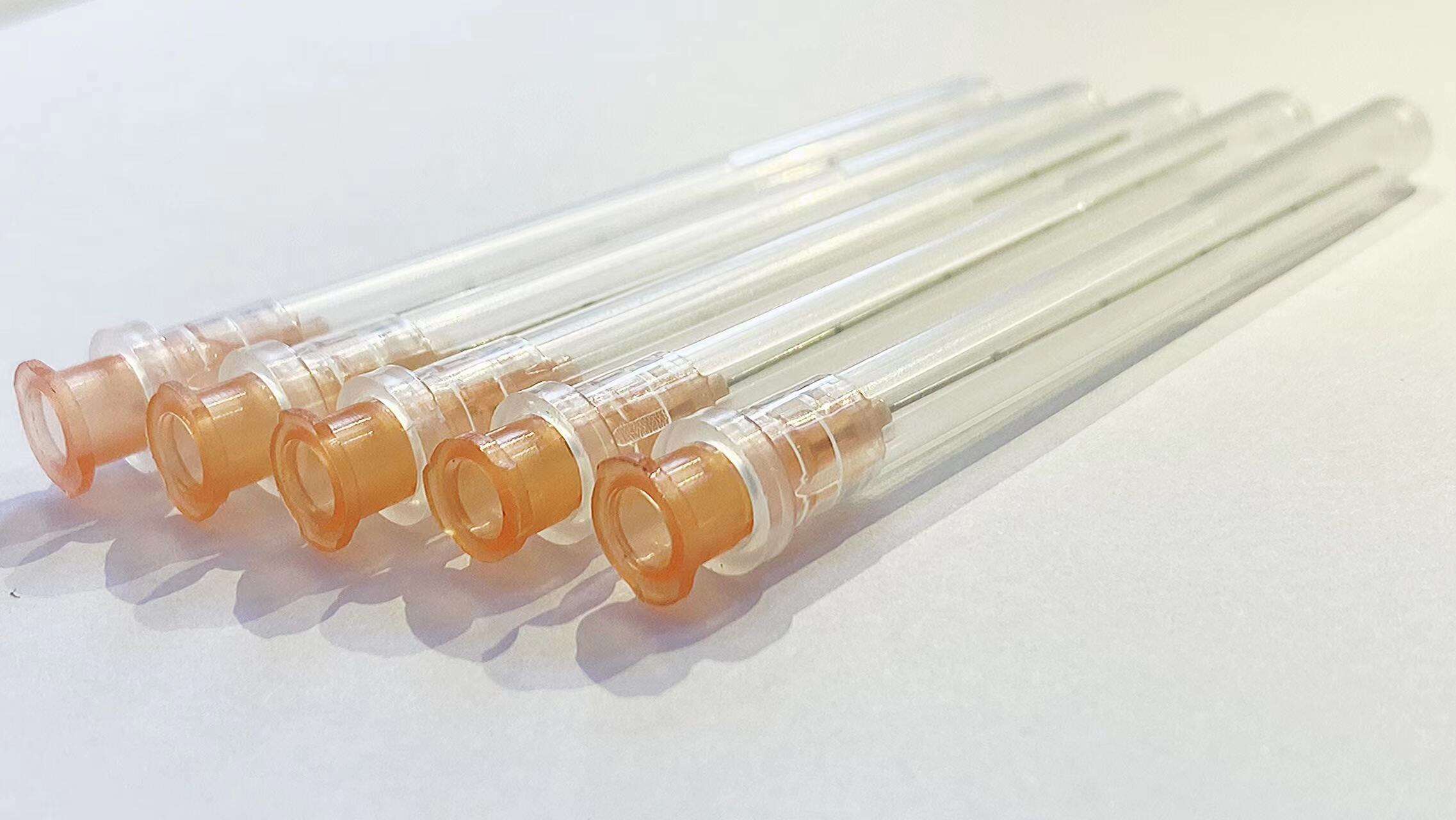

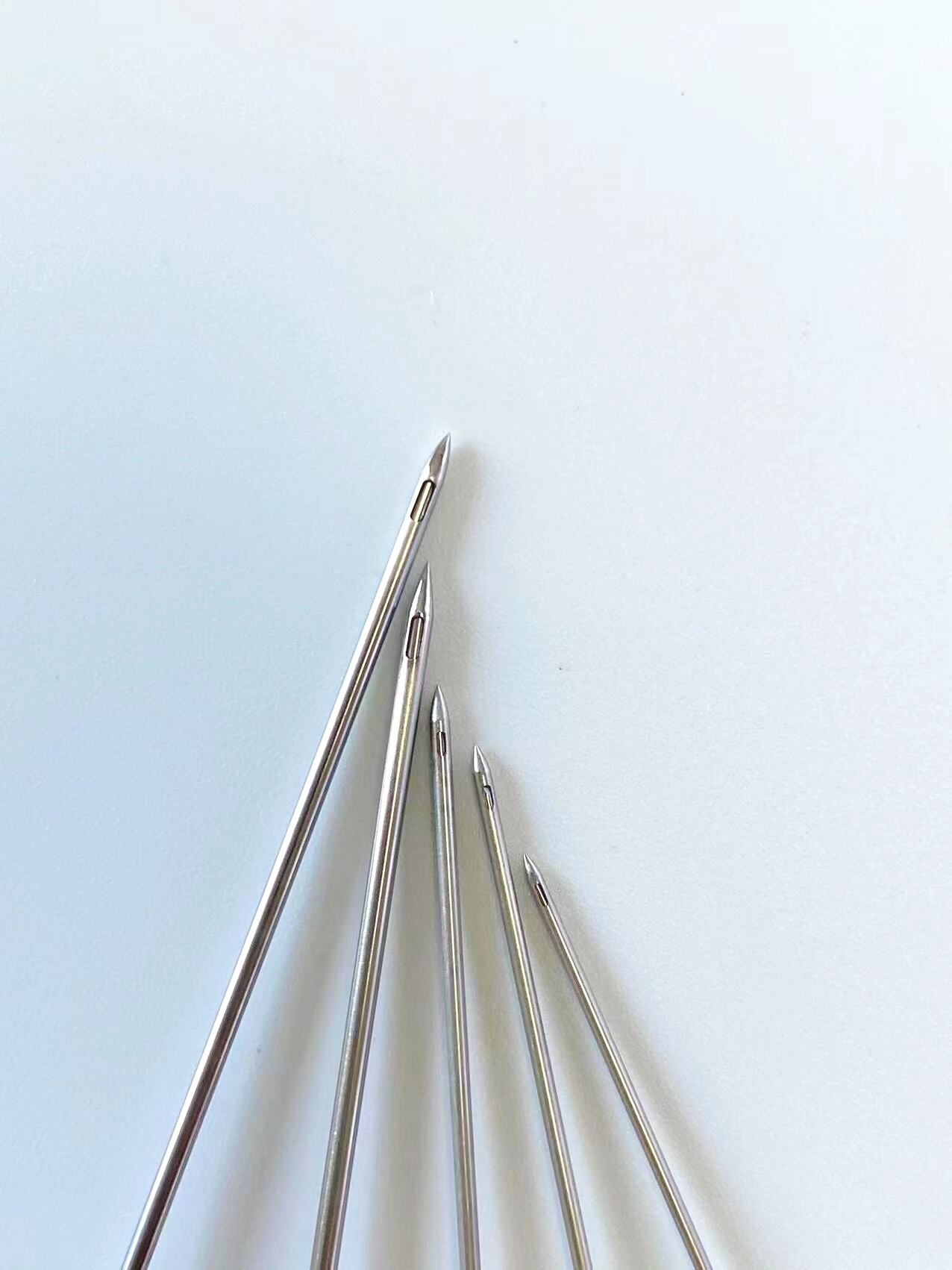

The extensive range of whitacre needle sizes provides healthcare professionals with unprecedented flexibility to customize treatment approaches based on individual patient characteristics and specific procedural requirements. Available in gauges ranging from 22 to 27, these needles accommodate diverse patient populations from pediatric to geriatric cases, ensuring optimal outcomes across all demographics. The 22-gauge whitacre needle sizes are ideal for procedures requiring rapid cerebrospinal fluid flow, making them perfect for therapeutic lumbar punctures and situations where larger volumes need to be withdrawn quickly. Medium-gauge options, including 24 and 25-gauge whitacre needle sizes, strike an optimal balance between flow rate and patient comfort, making them the preferred choice for routine spinal anesthesia and diagnostic procedures. The finest 27-gauge whitacre needle sizes offer maximum patient comfort with minimal tissue disruption, particularly beneficial for pediatric patients, elderly individuals with fragile tissues, or procedures where patient comfort is paramount. Each size variation maintains the signature pencil-point design while optimizing specific performance characteristics such as insertion force, cerebrospinal fluid flow rate, and tissue trauma minimization. Healthcare providers can select the most appropriate whitacre needle sizes based on patient anatomy, procedure complexity, and clinical objectives, ensuring personalized care delivery. The color-coded hub system corresponding to each gauge size enables rapid identification and selection, reducing preparation time and minimizing the risk of using incorrect needle sizes during critical procedures. This comprehensive range eliminates the need for medical facilities to stock multiple needle brands or types, simplifying inventory management while maintaining clinical versatility. The consistent manufacturing standards across all whitacre needle sizes guarantee uniform performance characteristics, allowing healthcare providers to predict and rely on specific behavioral patterns regardless of the chosen gauge. Training programs benefit from this standardization, as medical professionals can develop expertise with the pencil-point technology that translates seamlessly across all available sizes.