tourniquet manufacturer

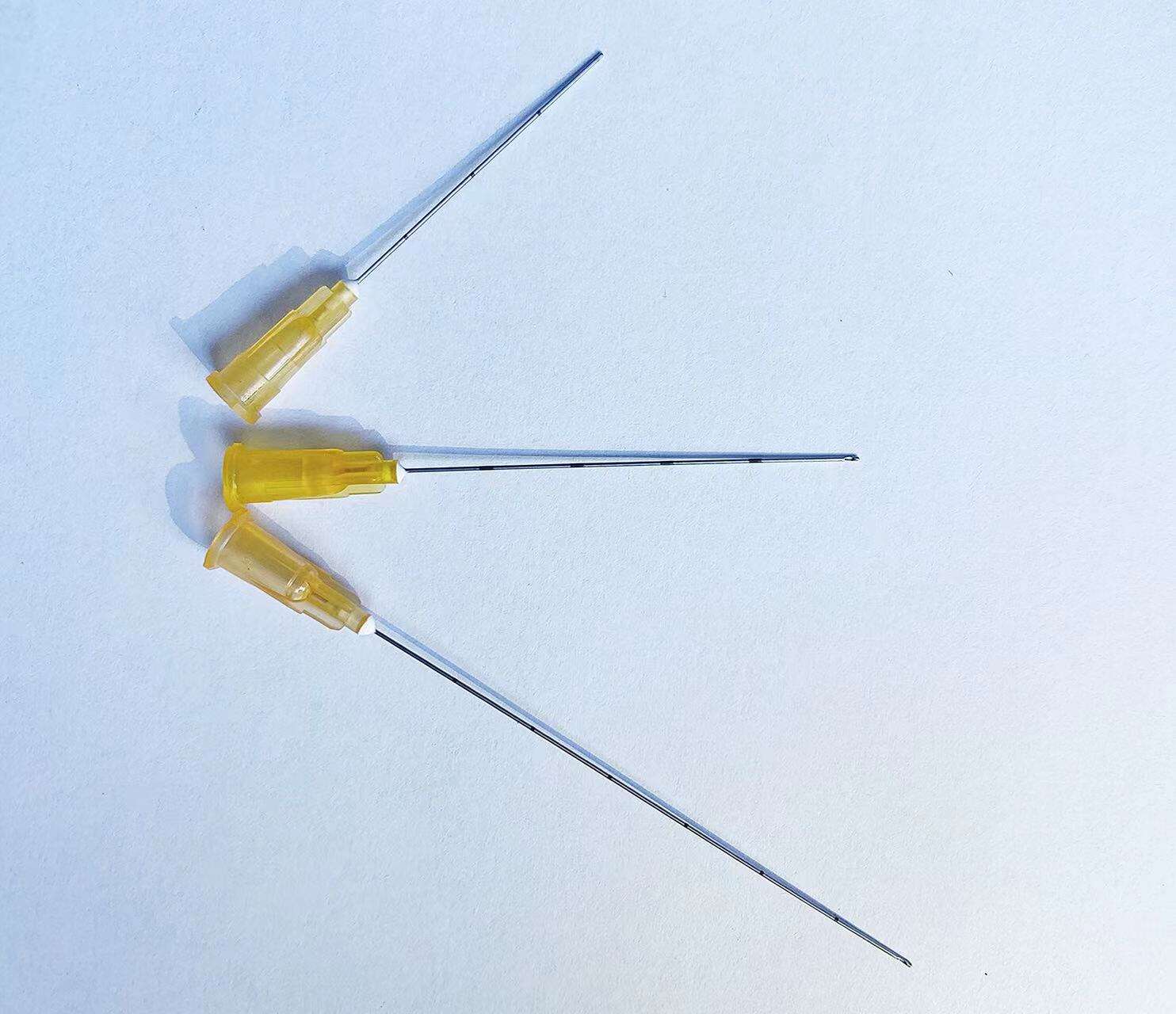

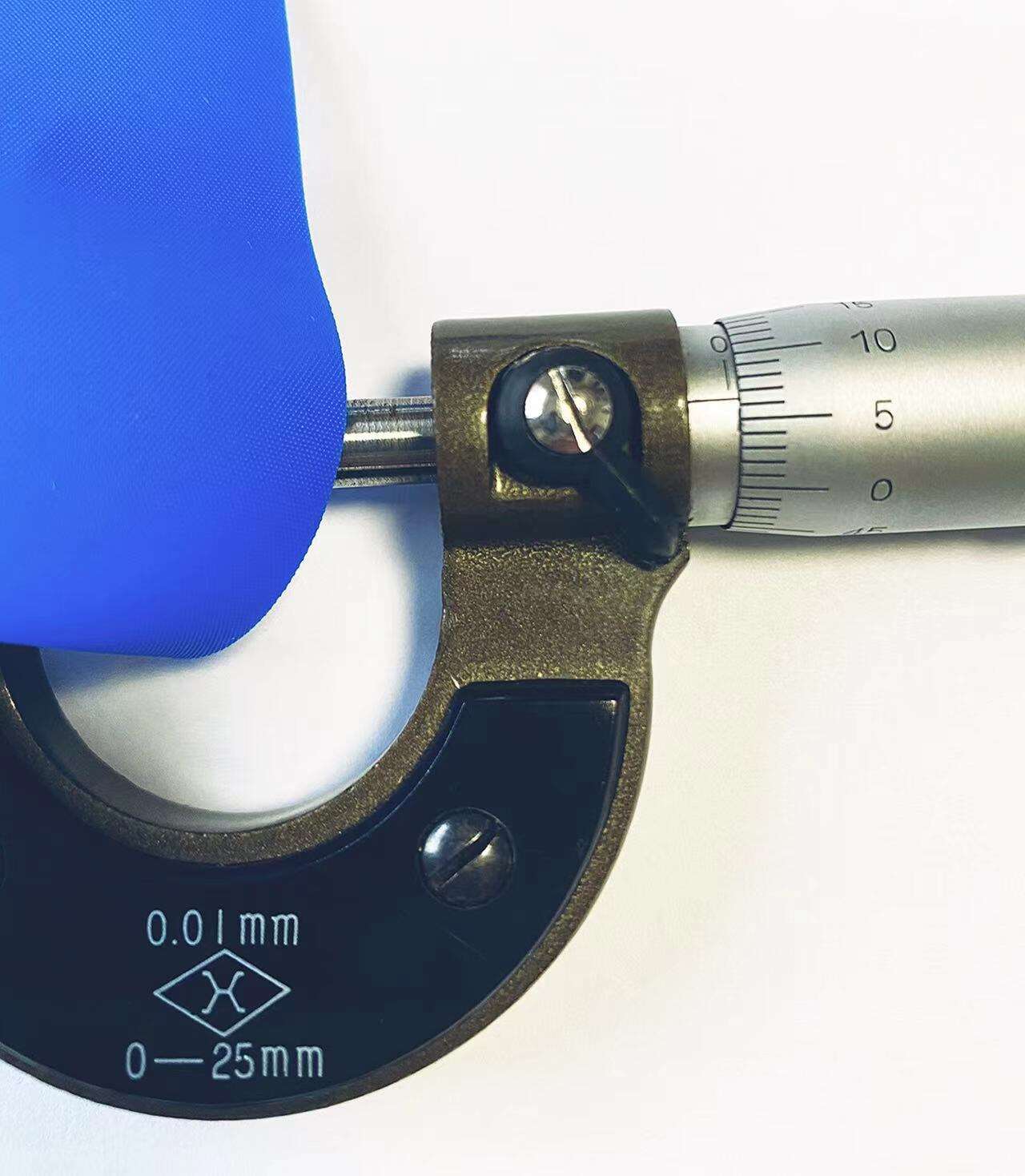

A tourniquet manufacturer specializes in designing, producing, and distributing life-saving medical devices that temporarily restrict blood flow to prevent excessive bleeding during emergencies, surgical procedures, and trauma care situations. These specialized companies focus on creating reliable, effective compression devices that can be rapidly deployed by medical professionals, first responders, and trained individuals in critical situations where hemorrhage control is paramount. The primary function of devices produced by a tourniquet manufacturer involves applying controlled pressure to limbs, effectively stopping arterial blood flow to prevent life-threatening blood loss from wounds, injuries, or during surgical interventions. Modern tourniquet manufacturer operations incorporate advanced materials science, ergonomic design principles, and rigorous testing protocols to ensure their products meet stringent medical standards and regulatory requirements. Technological features developed by leading tourniquet manufacturer companies include one-handed application mechanisms, pressure indicators, windlass systems for precise tension control, and durable construction materials that maintain effectiveness across various environmental conditions. These manufacturers utilize high-strength fabrics, corrosion-resistant hardware, and innovative buckle systems that enable quick, secure application even under stress. Applications for products from a tourniquet manufacturer span multiple sectors including military operations, emergency medical services, hospital surgical departments, wilderness medicine, law enforcement agencies, and civilian first aid programs. The devices prove essential in battlefield medicine, accident scenes, natural disaster response, and any scenario where rapid hemorrhage control can determine patient survival outcomes. Quality tourniquet manufacturer operations maintain strict quality assurance protocols, conduct extensive field testing, and continuously innovate to improve device reliability, ease of use, and patient safety outcomes across diverse medical and emergency response applications.