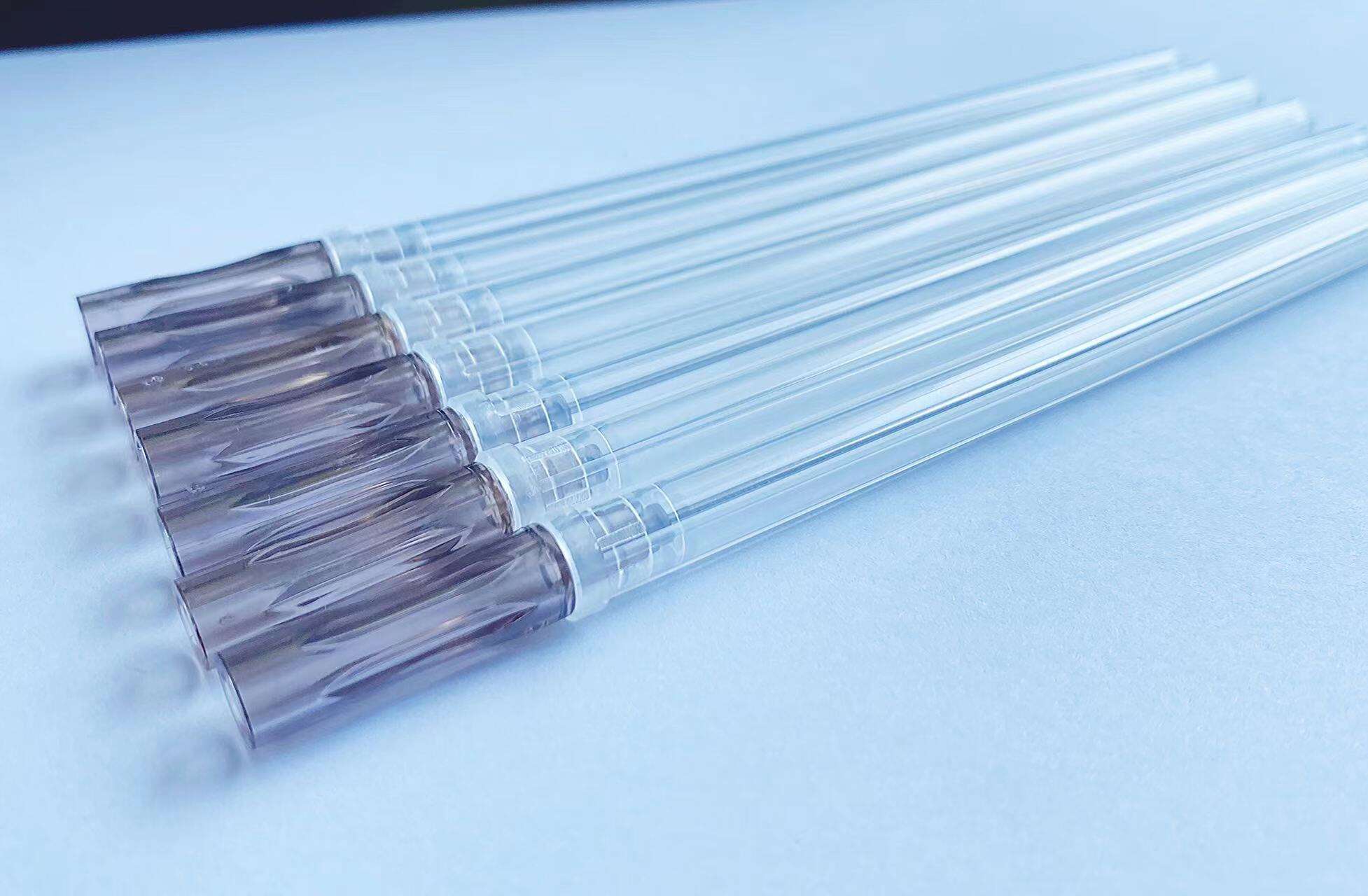

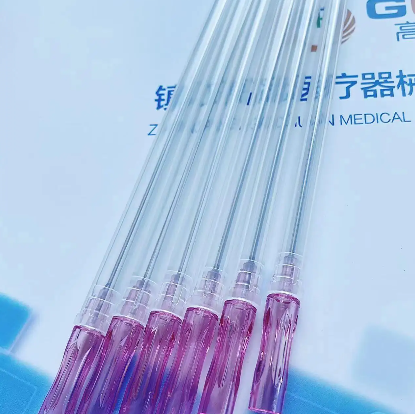

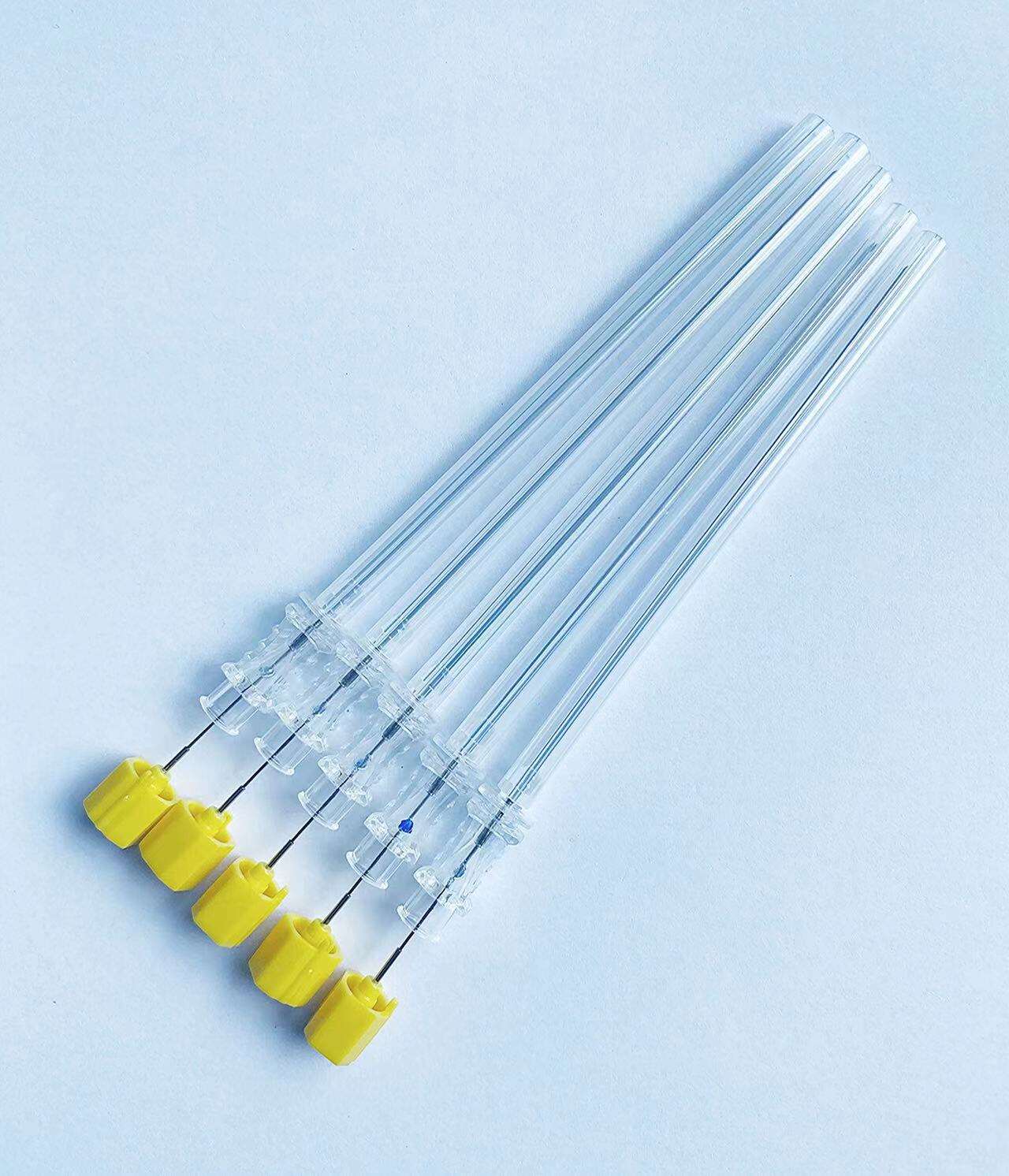

spinocan spinal needle

The spinocan spinal needle represents a significant advancement in spinal anesthesia and lumbar puncture procedures, offering healthcare professionals a reliable and precise instrument for various medical applications. This specialized medical device is engineered to deliver exceptional performance in spinal interventions, combining innovative design elements with practical functionality. The spinocan spinal needle features a unique construction that prioritizes patient comfort while maintaining the accuracy required for successful procedures. Its primary functions include facilitating spinal anesthesia administration, enabling cerebrospinal fluid sampling, and supporting various diagnostic and therapeutic spinal interventions. The needle incorporates advanced technological features such as a specially designed tip configuration that reduces tissue trauma during insertion. The spinocan spinal needle utilizes a cutting-edge bevel design that allows for smooth penetration through tissue layers while minimizing patient discomfort. The shaft construction employs high-grade stainless steel materials that provide optimal strength and flexibility during procedures. Healthcare professionals appreciate the ergonomic hub design that ensures secure grip and precise control throughout the insertion process. The spinocan spinal needle finds extensive applications in operating rooms, emergency departments, and outpatient facilities where spinal procedures are performed. Anesthesiologists rely on this instrument for administering epidural and spinal blocks during surgical procedures, while neurologists utilize it for diagnostic lumbar punctures. The versatility of the spinocan spinal needle makes it suitable for both routine and complex spinal interventions across various medical specialties. Its consistent performance characteristics have made it a preferred choice among medical professionals who demand reliability and precision in their spinal procedures. The manufacturing process incorporates stringent quality control measures to ensure each spinocan spinal needle meets the highest medical device standards for safety and effectiveness.