Versatile Applications Across Medical Specialties

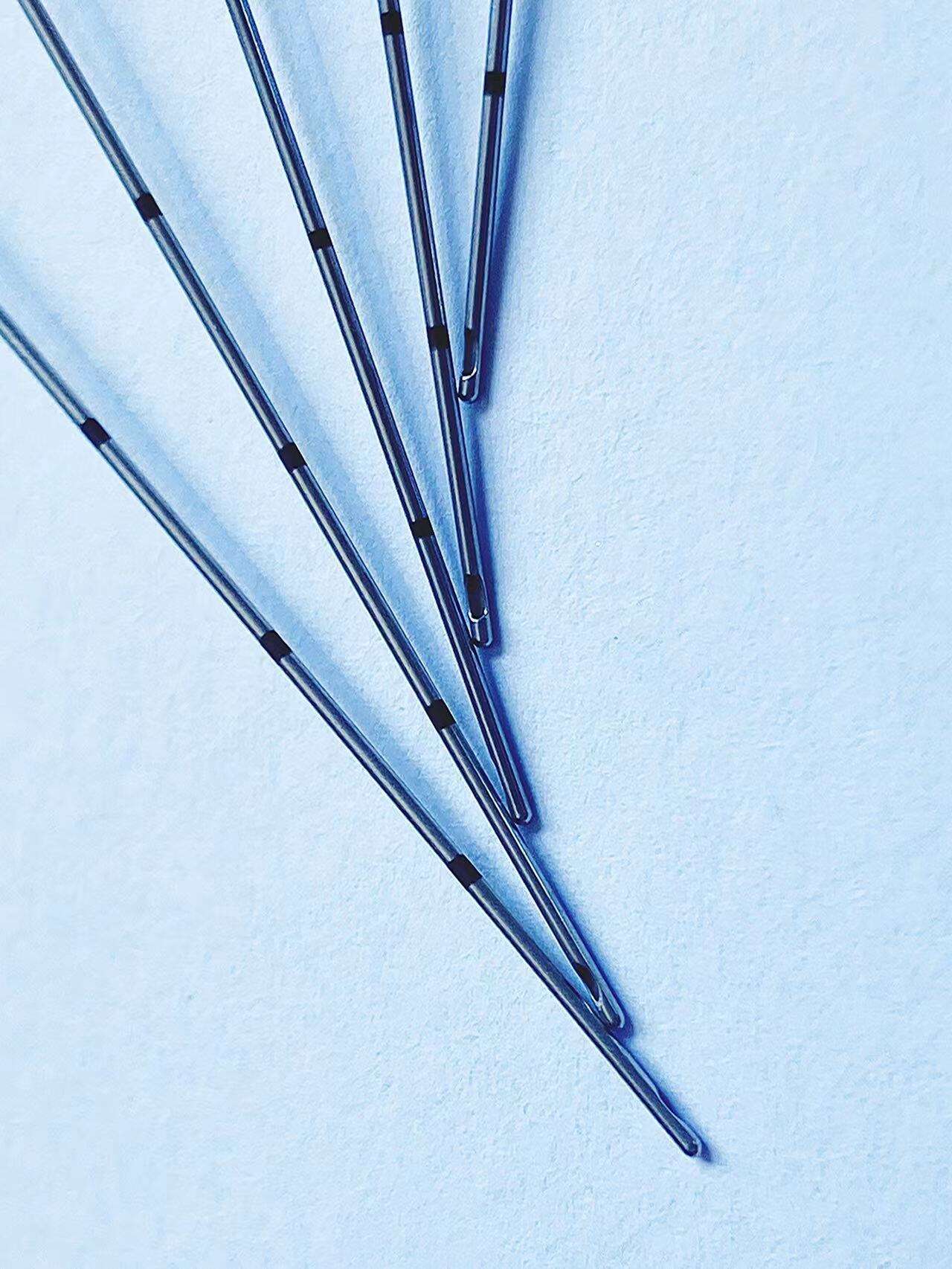

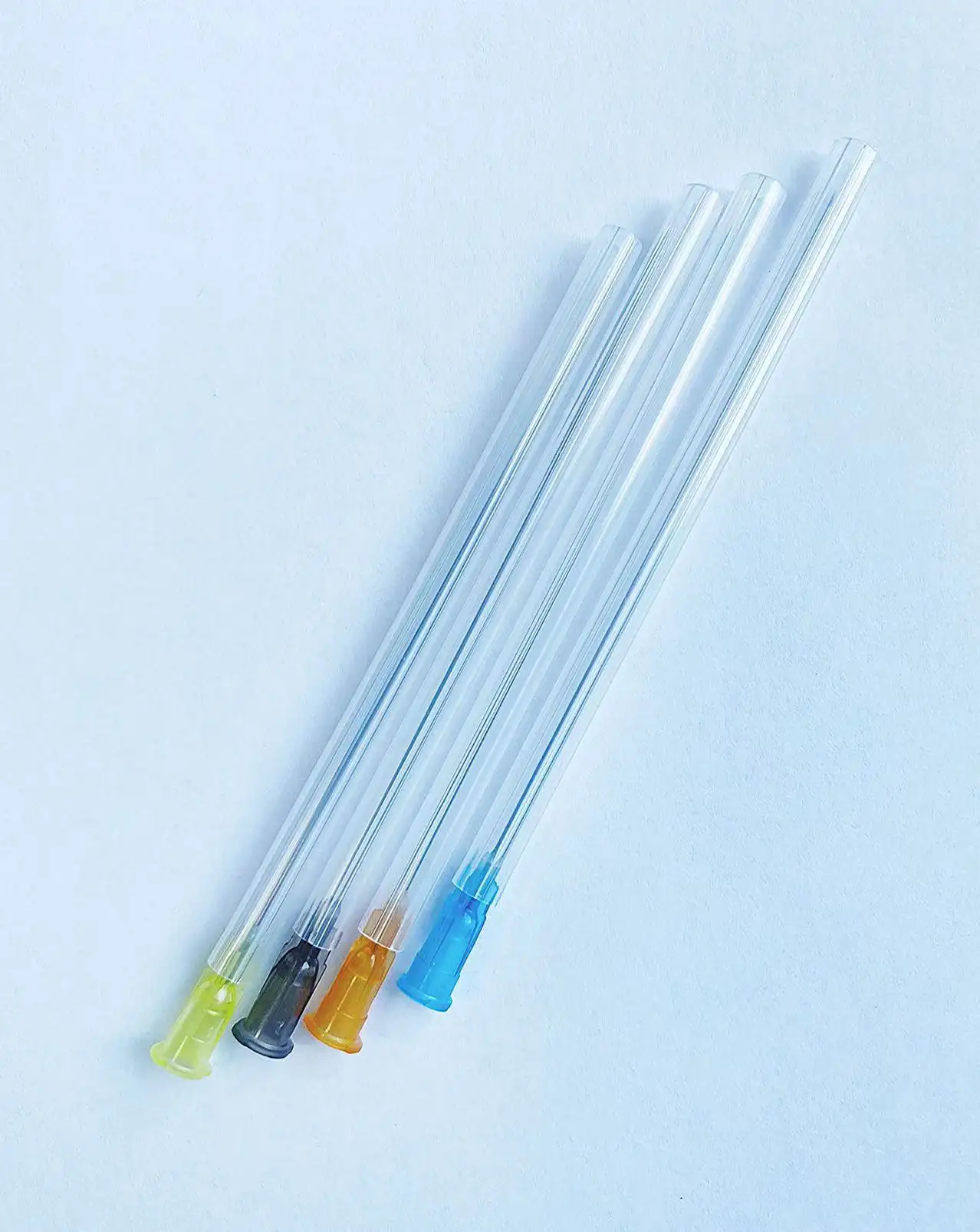

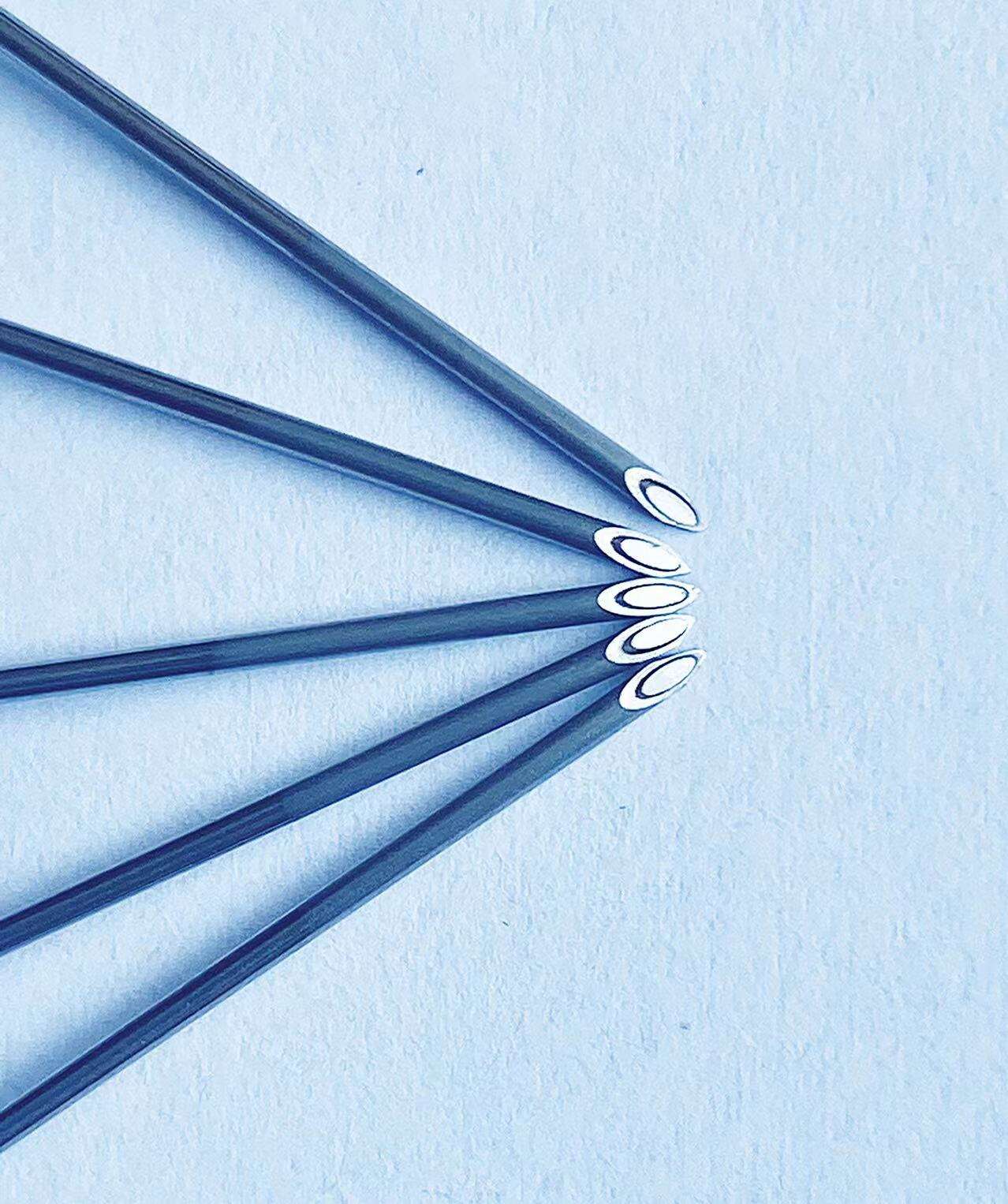

The versatile applications of spine needles across multiple medical specialties demonstrate their fundamental importance in modern healthcare delivery, providing essential capabilities for diagnostic and therapeutic procedures throughout various clinical disciplines. In anesthesiology practice, spine needles serve as indispensable instruments for administering spinal and epidural anesthesia during surgical procedures, enabling precise medication delivery to specific anatomical locations within the spinal canal. The versatility of these instruments allows anesthesiologists to adapt their techniques based on patient anatomy, procedural requirements, and clinical conditions, ensuring optimal anesthetic outcomes across diverse surgical specialties. Neurology departments rely extensively on spine needles for diagnostic lumbar punctures, enabling physicians to collect cerebrospinal fluid samples for laboratory analysis that can reveal critical information about neurological conditions, infections, and other pathological processes affecting the central nervous system. The precision capabilities of modern spine needles facilitate accurate sample collection while minimizing patient discomfort and procedural complications. Pain management specialists utilize spine needles for targeted therapeutic interventions, including epidural steroid injections, nerve blocks, and other minimally invasive treatments that provide significant relief for patients suffering from chronic back pain conditions. The versatility of spine needles enables pain management practitioners to access specific anatomical targets with remarkable precision, delivering therapeutic agents directly to affected areas for maximum treatment efficacy. Emergency medicine applications of spine needles include urgent diagnostic procedures and therapeutic interventions that may be required in critical care situations, where rapid and accurate spinal access can be life-saving. The reliability and consistent performance of these instruments make them essential components of emergency medical equipment inventories. Orthopedic surgery applications encompass both diagnostic and therapeutic uses, where spine needles facilitate precise medication delivery and tissue sampling procedures that support comprehensive patient care. The adaptability of spine needles to various procedural approaches and imaging guidance systems enhances their utility across different medical specialties, making them valuable tools for interdisciplinary healthcare teams working collaboratively on complex patient cases.