epidural needle gauge

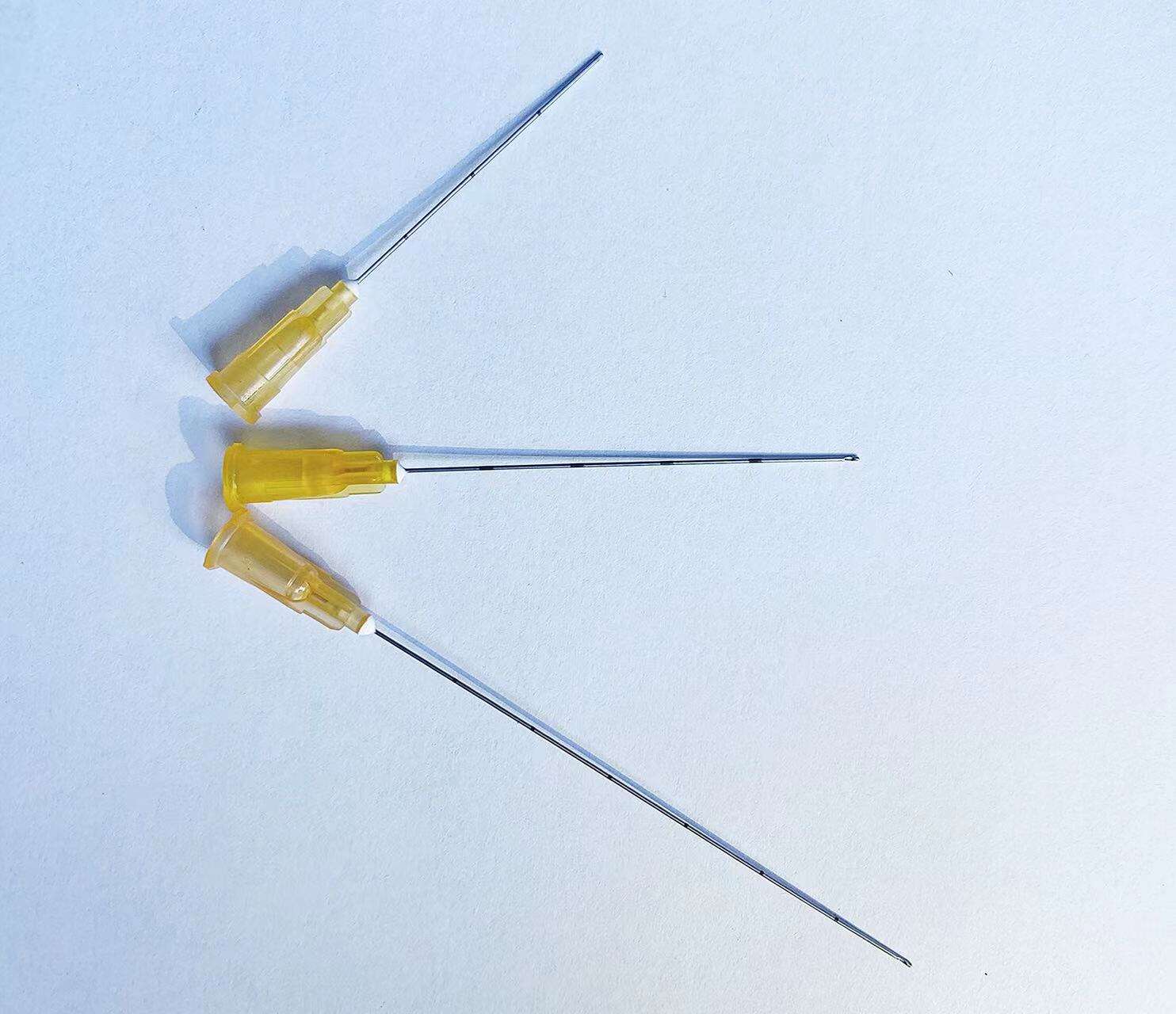

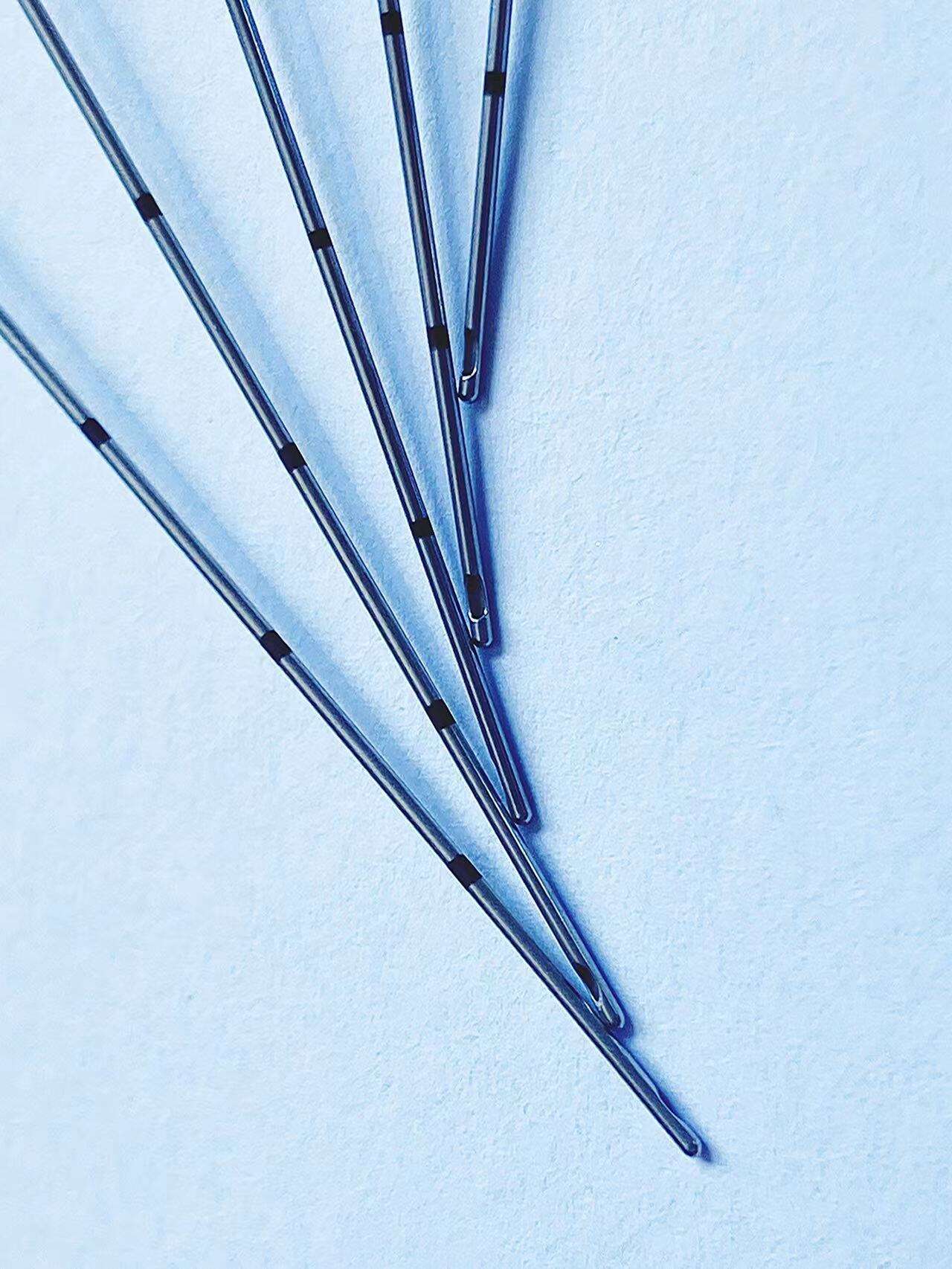

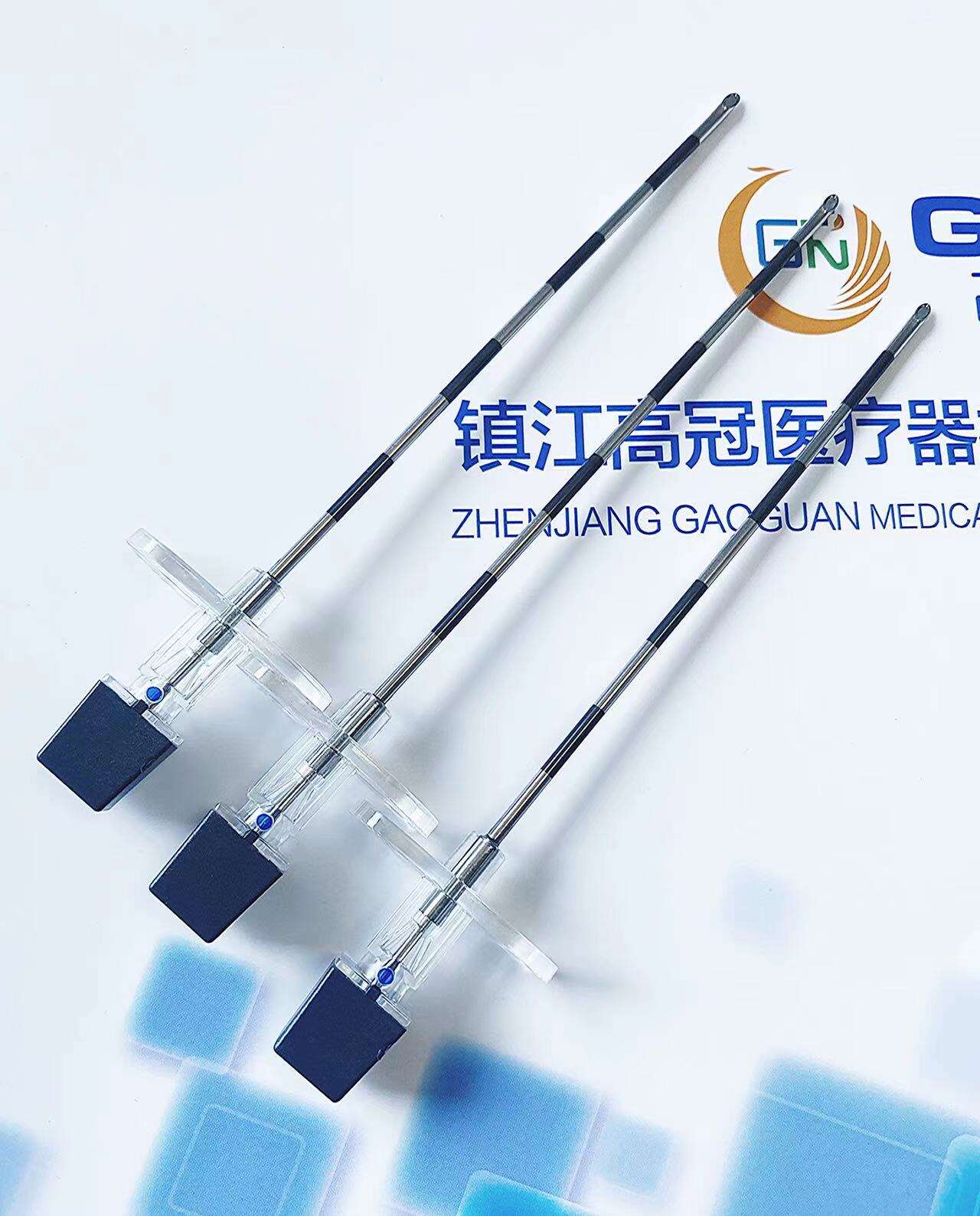

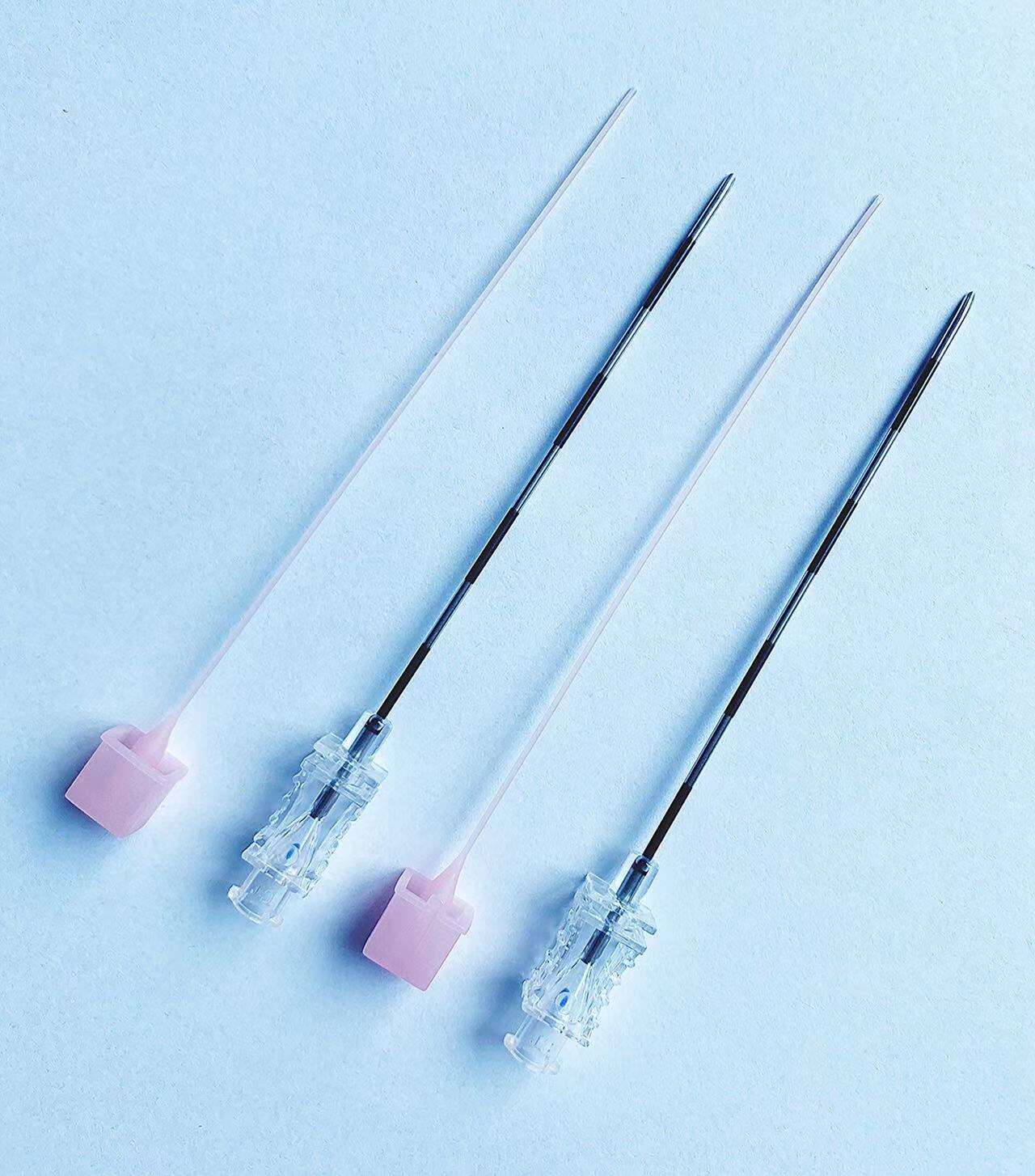

The epidural needle gauge represents a critical measurement system that determines the diameter and thickness of epidural needles used in regional anesthesia and pain management procedures. This standardized gauge system enables healthcare professionals to select the appropriate needle size for specific medical applications, ensuring optimal patient outcomes and procedural success. The epidural needle gauge typically ranges from 16 to 22 gauge, with smaller numbers indicating larger needle diameters. Understanding the epidural needle gauge is essential for anesthesiologists, pain management specialists, and other medical practitioners who perform epidural procedures. The gauge measurement directly impacts the flow rate of medications, patient comfort levels, and overall procedural efficiency. Modern epidural needle gauge systems incorporate advanced technological features that enhance precision and reliability. These needles feature specialized tip designs, including pencil-point and cutting-edge configurations, which work in conjunction with the specific gauge measurements to optimize tissue penetration and minimize trauma. The epidural needle gauge also influences the choice of catheter compatibility, as different gauge sizes accommodate varying catheter diameters for continuous infusion procedures. Healthcare facilities rely on standardized epidural needle gauge measurements to maintain consistency across different manufacturers and ensure proper inventory management. The gauge system facilitates accurate documentation and communication between medical professionals, reducing the risk of errors during needle selection. Advanced manufacturing processes ensure that epidural needle gauge specifications meet stringent quality standards and regulatory requirements. The relationship between epidural needle gauge and clinical outcomes has been extensively studied, with research demonstrating that appropriate gauge selection significantly impacts procedure duration, patient satisfaction, and complication rates. Modern epidural needle gauge technology incorporates safety features such as depth markings and hub designs that enhance procedural control and reduce the risk of inadvertent advancement.