Precision Engineering for Optimal Medication Delivery

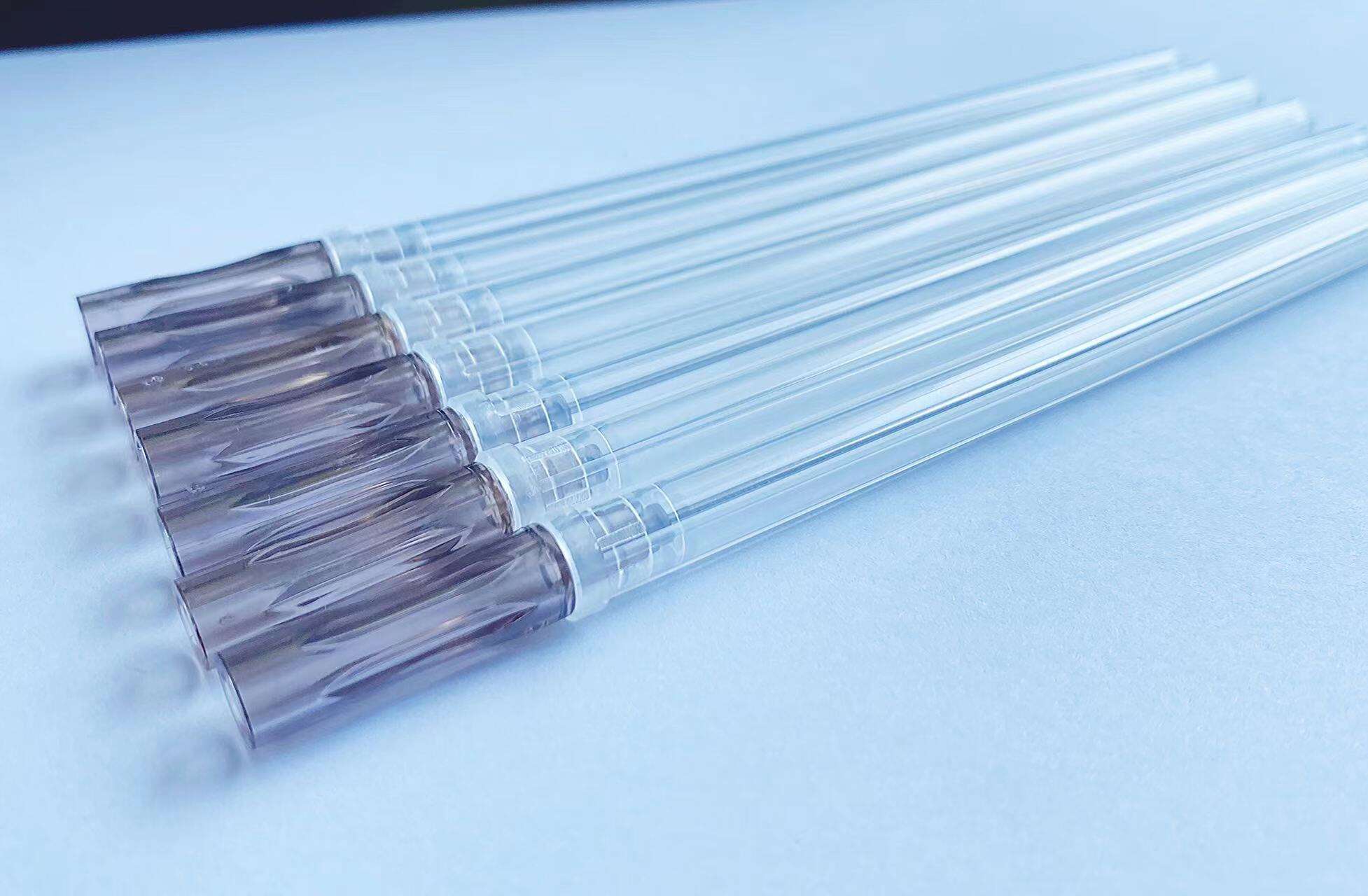

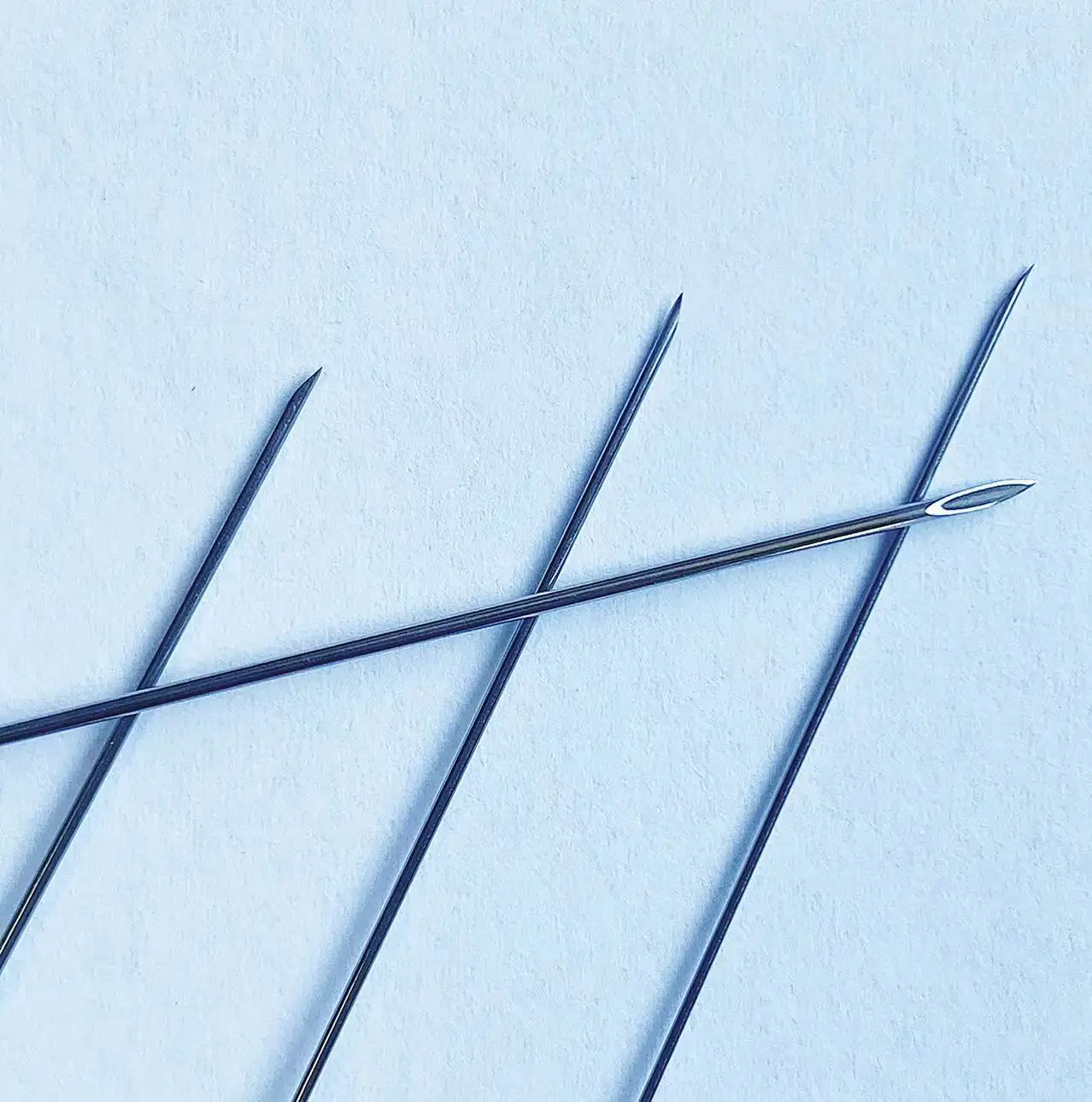

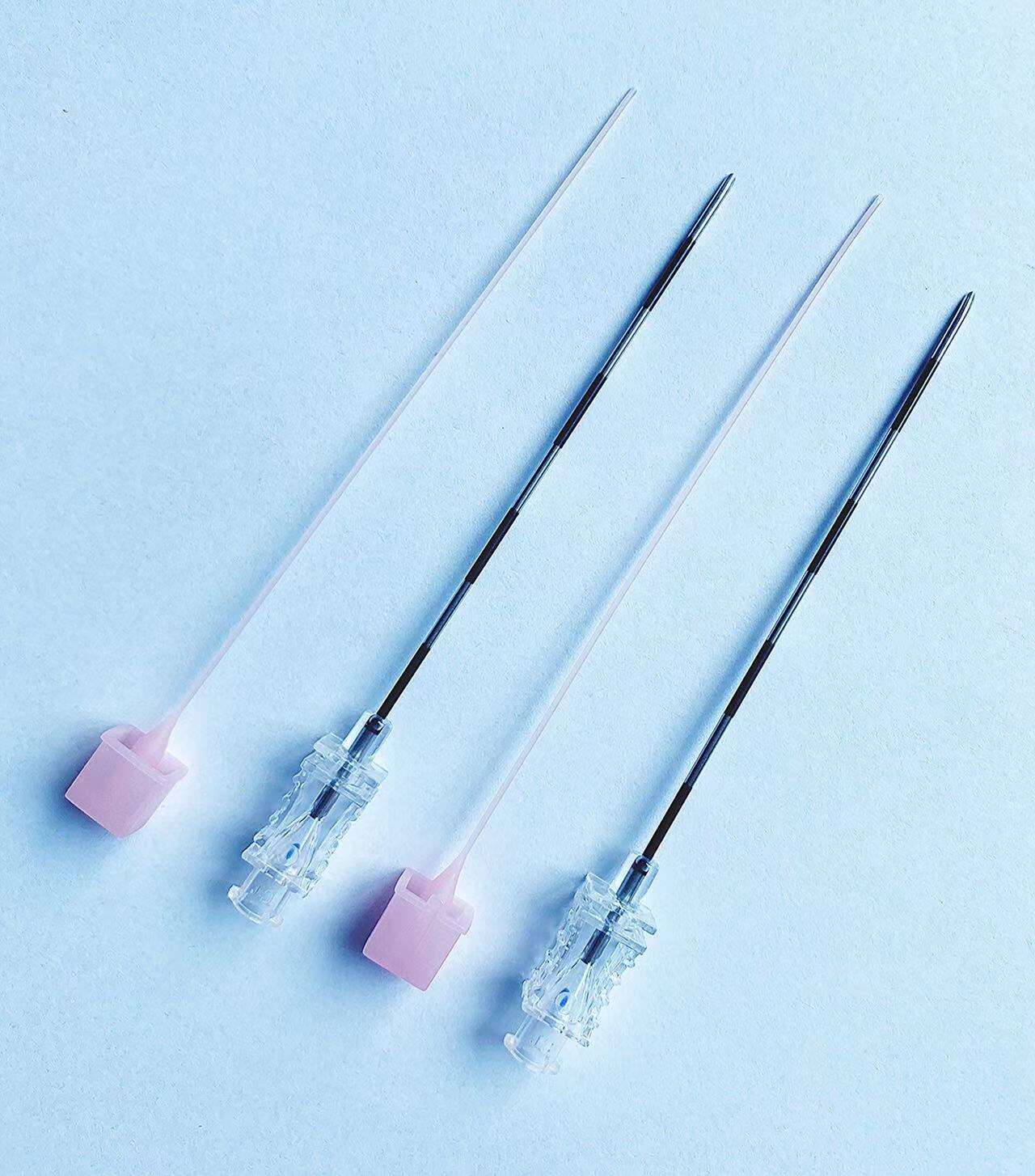

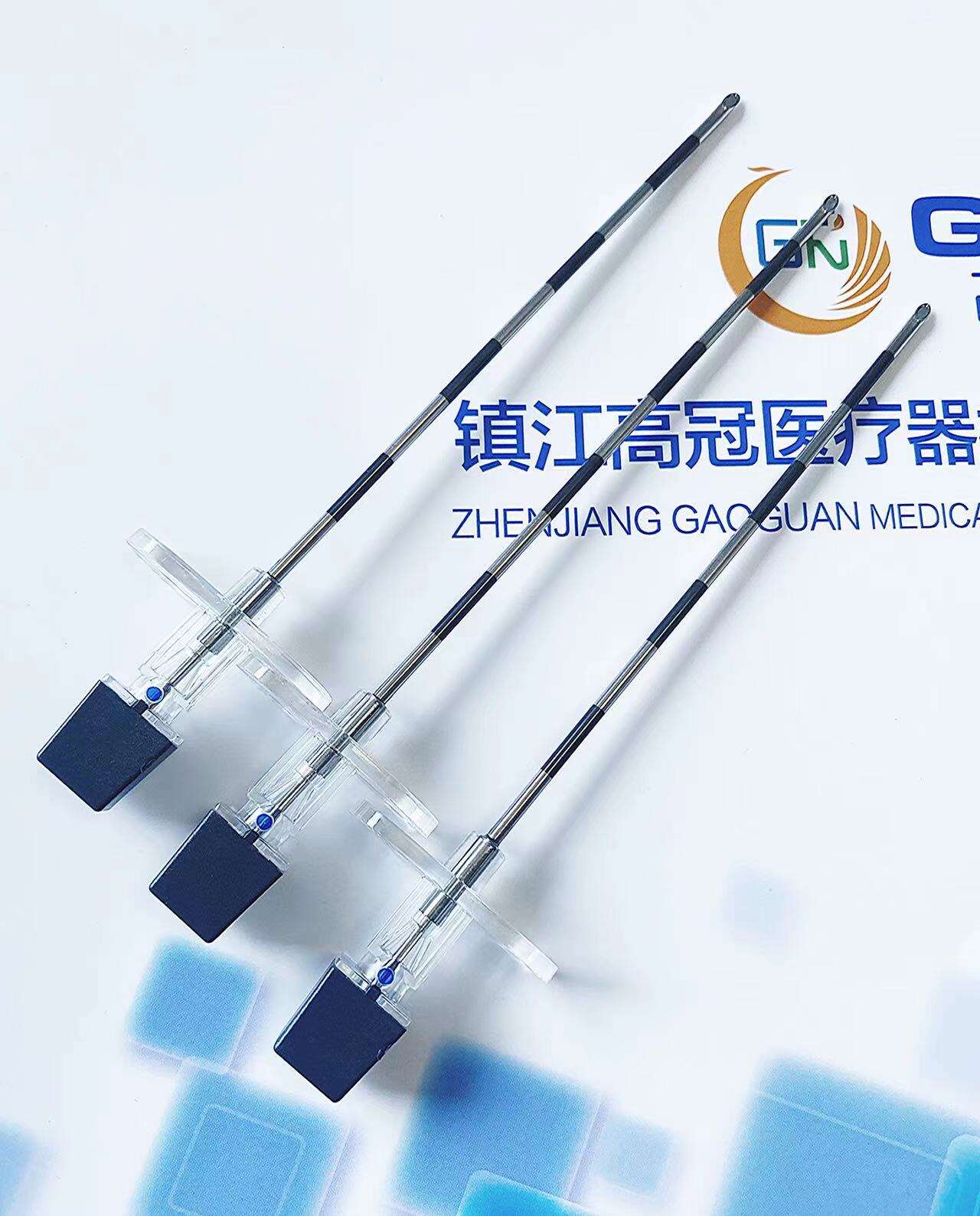

The epidural syringe showcases exceptional precision engineering that ensures optimal medication delivery throughout various medical procedures. This sophisticated medical instrument incorporates multiple design elements that work together to provide unparalleled accuracy in drug administration, making it an indispensable tool for healthcare professionals performing epidural procedures. The precision engineering begins with the syringe barrel, which features exact internal dimensions that minimize dead space and ensure complete medication delivery without waste. The smooth interior surface reduces friction during plunger movement, allowing for consistent flow rates and predictable medication distribution. The graduated markings on the barrel provide precise volume measurements, enabling healthcare providers to administer exact dosages according to treatment protocols. These markings are laser-etched for durability and clarity, ensuring accurate readings even under challenging lighting conditions in operating rooms or delivery suites. The plunger mechanism represents another aspect of the epidural syringe's precision engineering, featuring a tight seal that prevents medication leakage while maintaining smooth operation. The plunger design incorporates advanced materials that provide optimal compression characteristics, ensuring consistent pressure transmission from the healthcare provider's hand to the medication being delivered. This precision in pressure control allows for controlled injection rates, which is crucial for patient comfort and procedural success. The epidural syringe's precision engineering extends to its needle compatibility system, which ensures secure connections that prevent accidental disconnections during procedures. The Luer-lock or similar connection mechanism provides a reliable seal that maintains sterility and prevents contamination while allowing for smooth medication flow. The engineering tolerances are precisely calculated to accommodate thermal expansion and contraction that may occur during sterilization processes, ensuring consistent performance across multiple use cycles for reusable models. Quality control measures during manufacturing ensure that each epidural syringe meets exacting specifications for internal volume, pressure resistance, and dimensional accuracy. These stringent standards guarantee that healthcare providers can rely on consistent performance from every syringe, reducing variability in procedural outcomes and enhancing patient safety.