good puncture set for local anesthesia

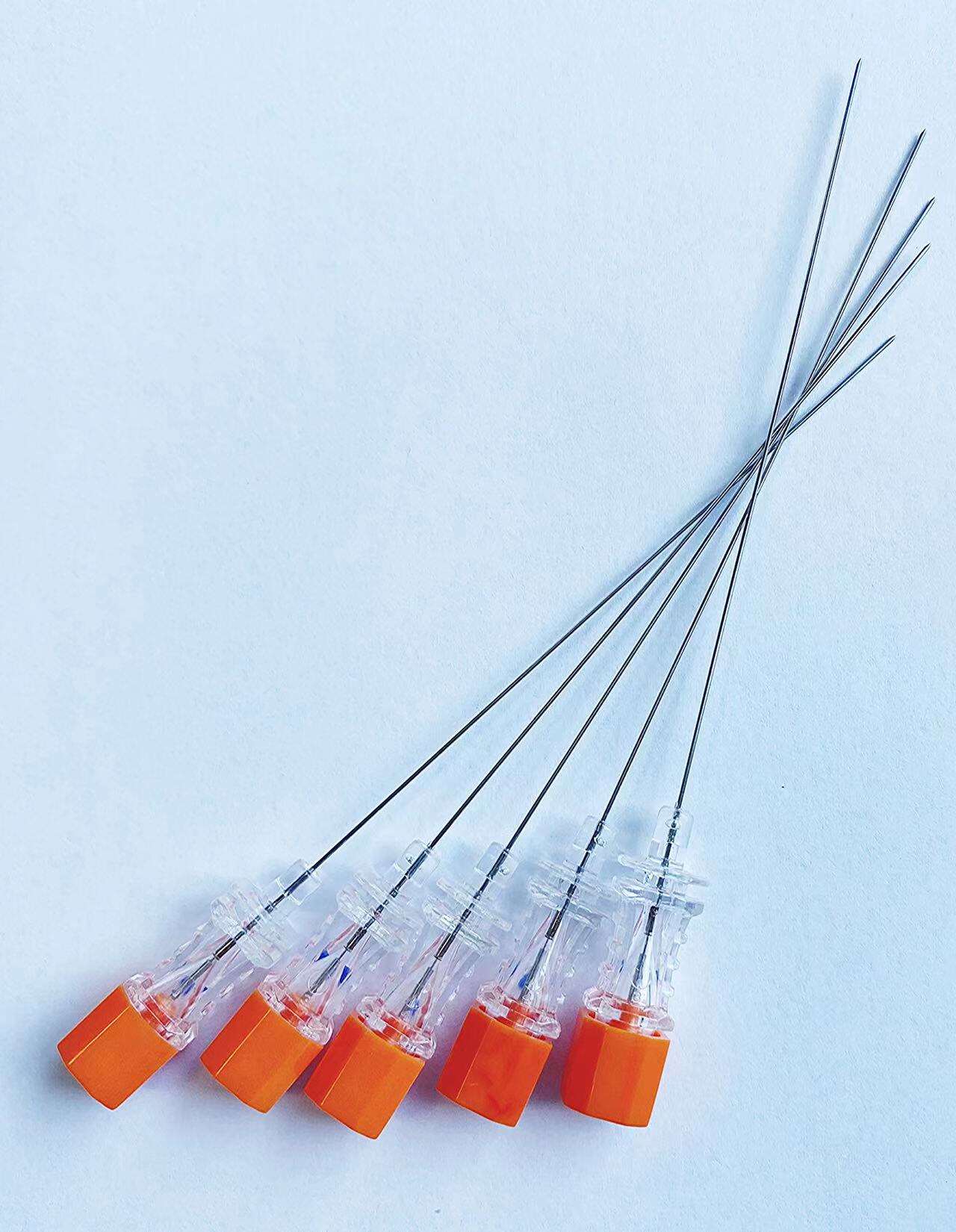

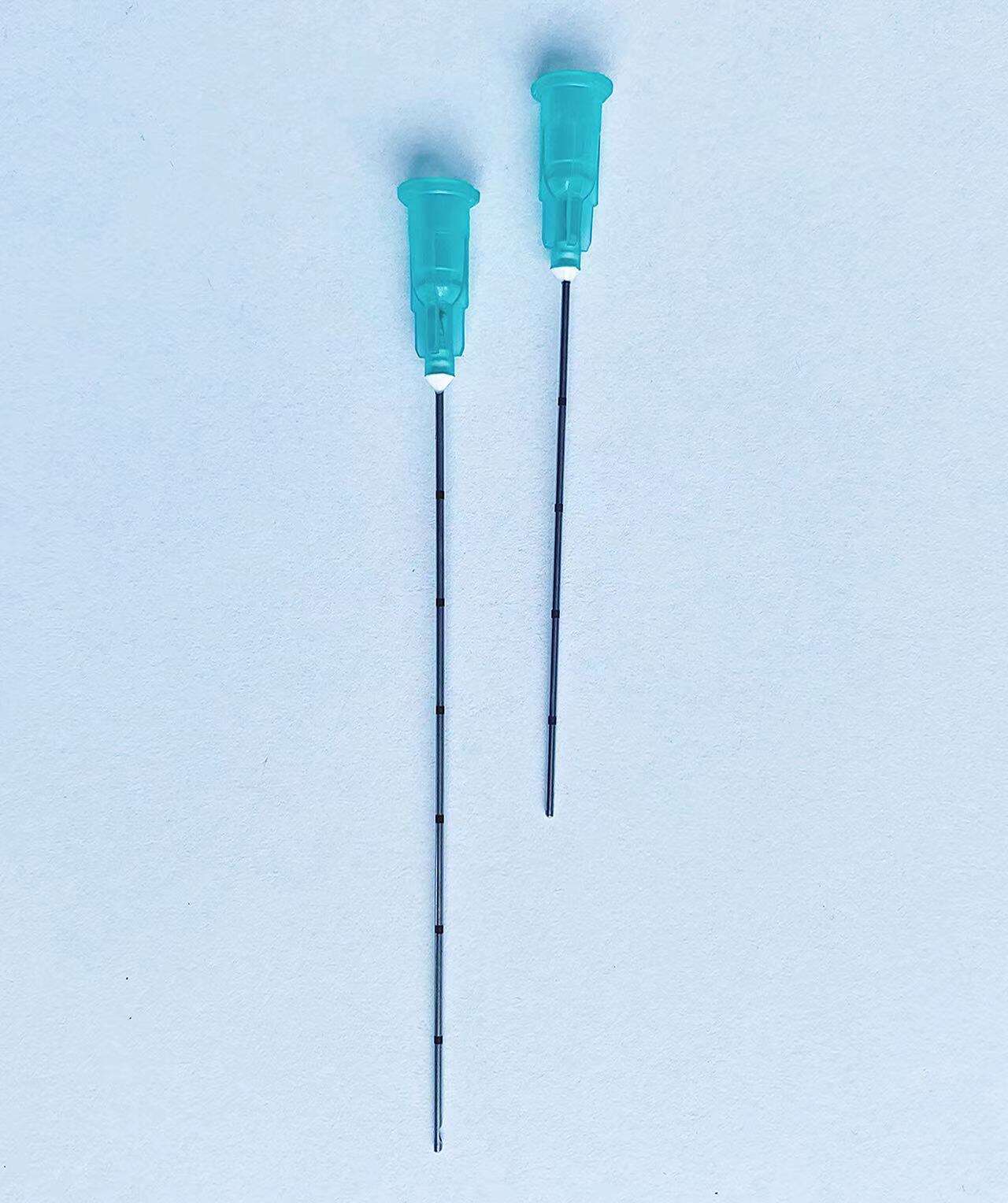

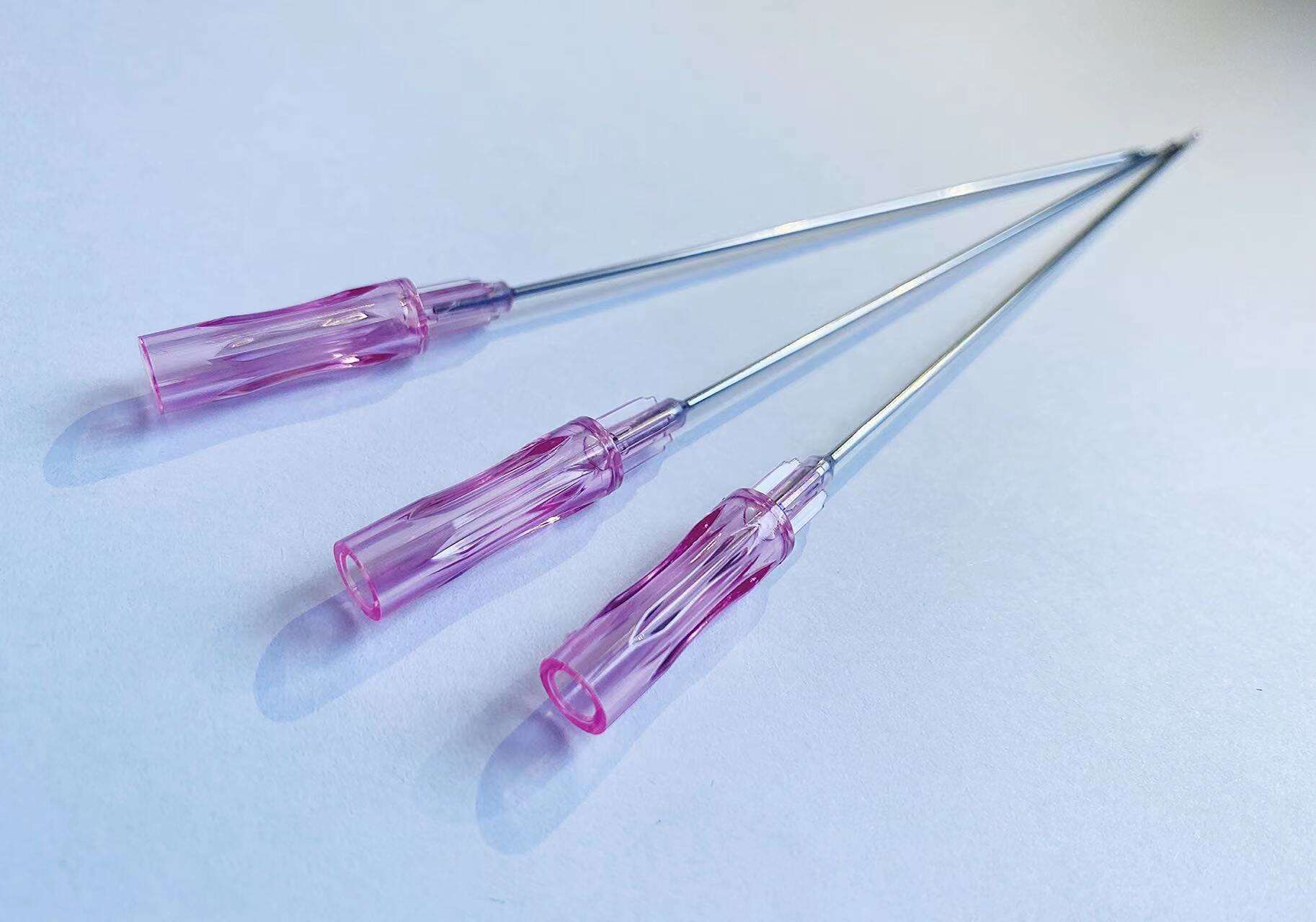

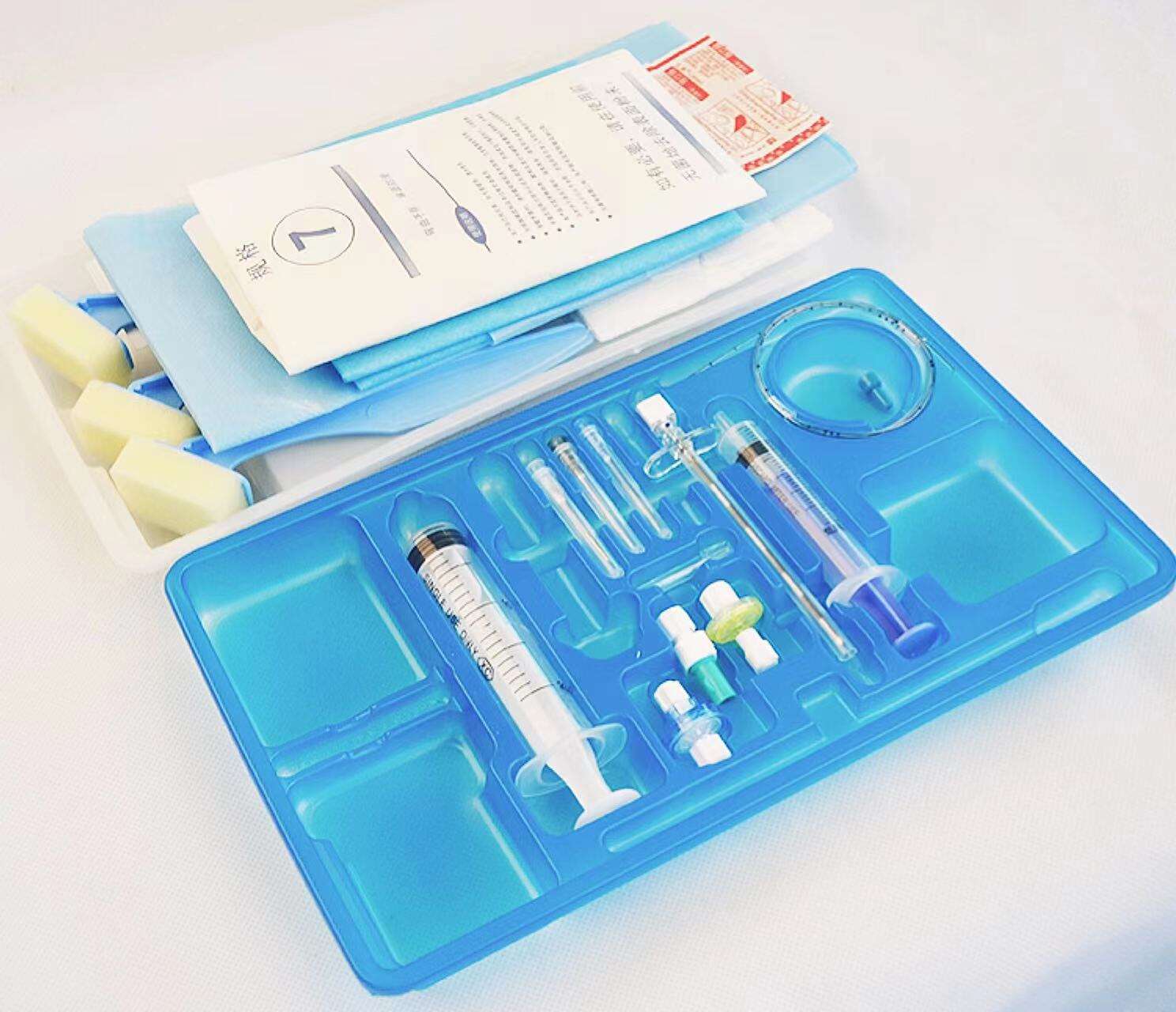

A good puncture set for local anesthesia represents an essential medical instrument system designed to deliver precise, safe, and effective anesthetic injections for various clinical procedures. This comprehensive medical device combines advanced engineering with user-friendly design principles to ensure optimal patient comfort and procedural success. The good puncture set for local anesthesia incorporates multiple specialized components, including precision needles, ergonomic syringes, and safety mechanisms that work together to create a superior injection experience. Modern puncture sets utilize cutting-edge materials such as medical-grade stainless steel and specialized polymers that enhance durability while maintaining biocompatibility standards. The technological features of a good puncture set for local anesthesia include ultra-sharp needle tips manufactured using advanced grinding techniques, which significantly reduce tissue trauma during insertion. These sets often feature color-coded components for easy identification, transparent barrel designs for accurate medication visualization, and graduated markings for precise dosage control. The needle geometry is specifically engineered to minimize insertion force while maximizing penetration accuracy, resulting in reduced patient discomfort and improved procedural efficiency. Applications for the good puncture set for local anesthesia span across numerous medical specialties, including dentistry, dermatology, plastic surgery, minor surgical procedures, and emergency medicine. Healthcare professionals rely on these instruments for administering lidocaine, procaine, and other local anesthetic agents with exceptional precision. The versatility of modern puncture sets allows for adaptation to various injection techniques, from superficial skin infiltration to deeper tissue blocks. Quality puncture sets also incorporate safety features such as needle shields, locking mechanisms, and disposal systems that protect healthcare workers from accidental needlestick injuries. The manufacturing process involves rigorous quality control measures, including sterility testing, dimensional verification, and performance validation to ensure consistent reliability across all units produced.