embedding needle supplier

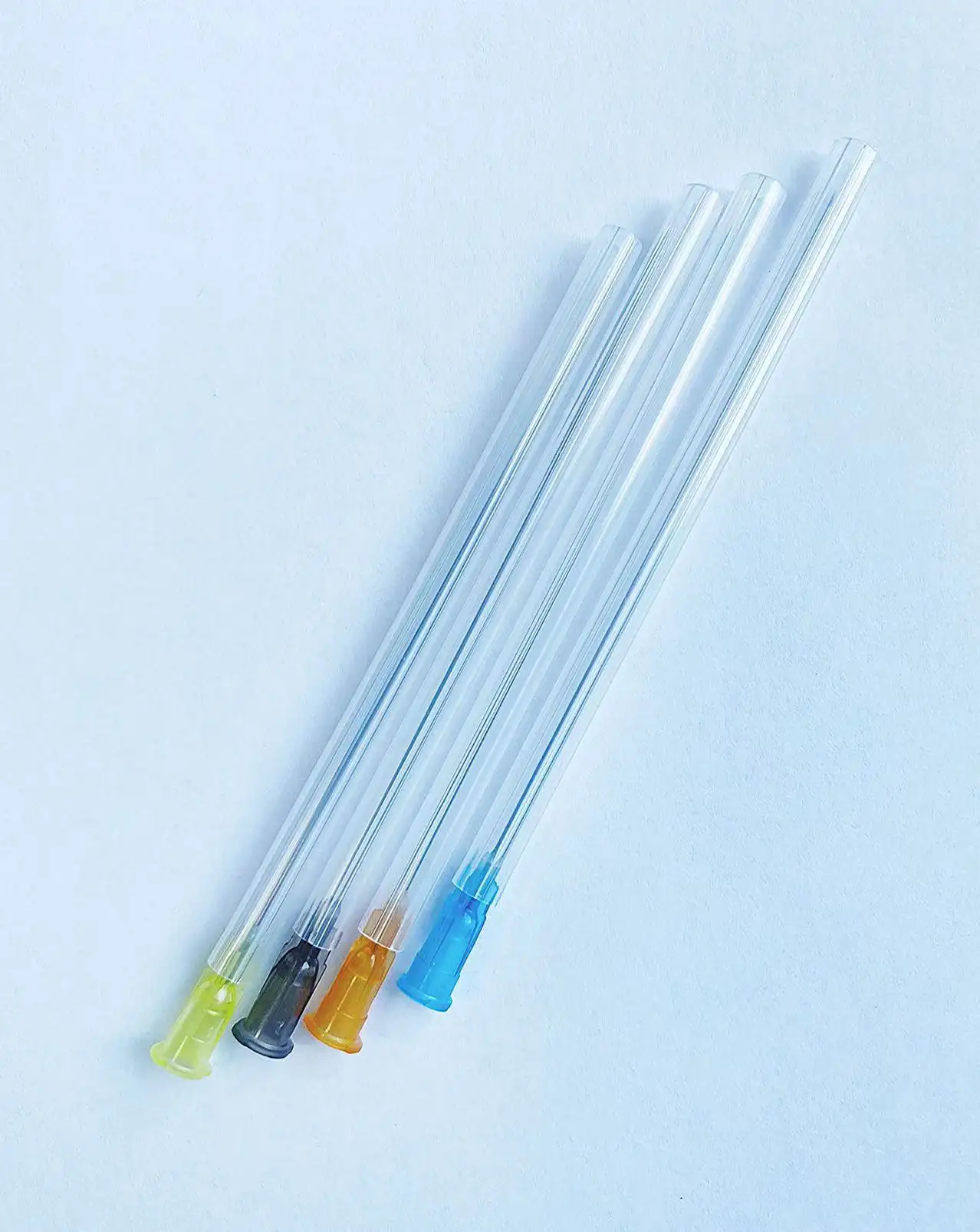

An embedding needle supplier serves as a specialized provider of precision medical instruments designed for minimally invasive procedures and tissue sampling applications. These suppliers focus on manufacturing and distributing high-quality needles that healthcare professionals use for various diagnostic and therapeutic interventions. The embedding needle supplier operates within the medical device industry, ensuring that hospitals, clinics, and research facilities have access to reliable needle solutions that meet stringent quality standards. The primary function of an embedding needle supplier involves developing needles with advanced tip geometries that minimize tissue trauma while maximizing sampling efficiency. These instruments feature ultra-sharp beveled edges and specialized coatings that reduce friction during insertion. The technological capabilities of a professional embedding needle supplier include state-of-the-art manufacturing processes that guarantee consistent needle dimensions and surface finishes. Quality control systems ensure that every needle meets medical-grade specifications for sterility and performance. Modern embedding needle supplier facilities utilize automated production lines that maintain precise tolerances and eliminate manufacturing defects. The applications for embedding needles span across multiple medical specialties including pathology, oncology, cardiology, and radiology. Healthcare providers rely on embedding needle supplier products for biopsy procedures, fluid extraction, and tissue marker placement. These needles enable physicians to obtain accurate diagnostic samples while minimizing patient discomfort and recovery time. Research institutions also depend on embedding needle supplier solutions for laboratory studies and experimental procedures. The embedding needle supplier industry continues to evolve with advancing medical technologies and changing healthcare requirements. Suppliers invest in research and development to create innovative needle designs that improve procedural outcomes and patient safety.