Comprehensive Size Range Optimizes Patient-Specific Treatment

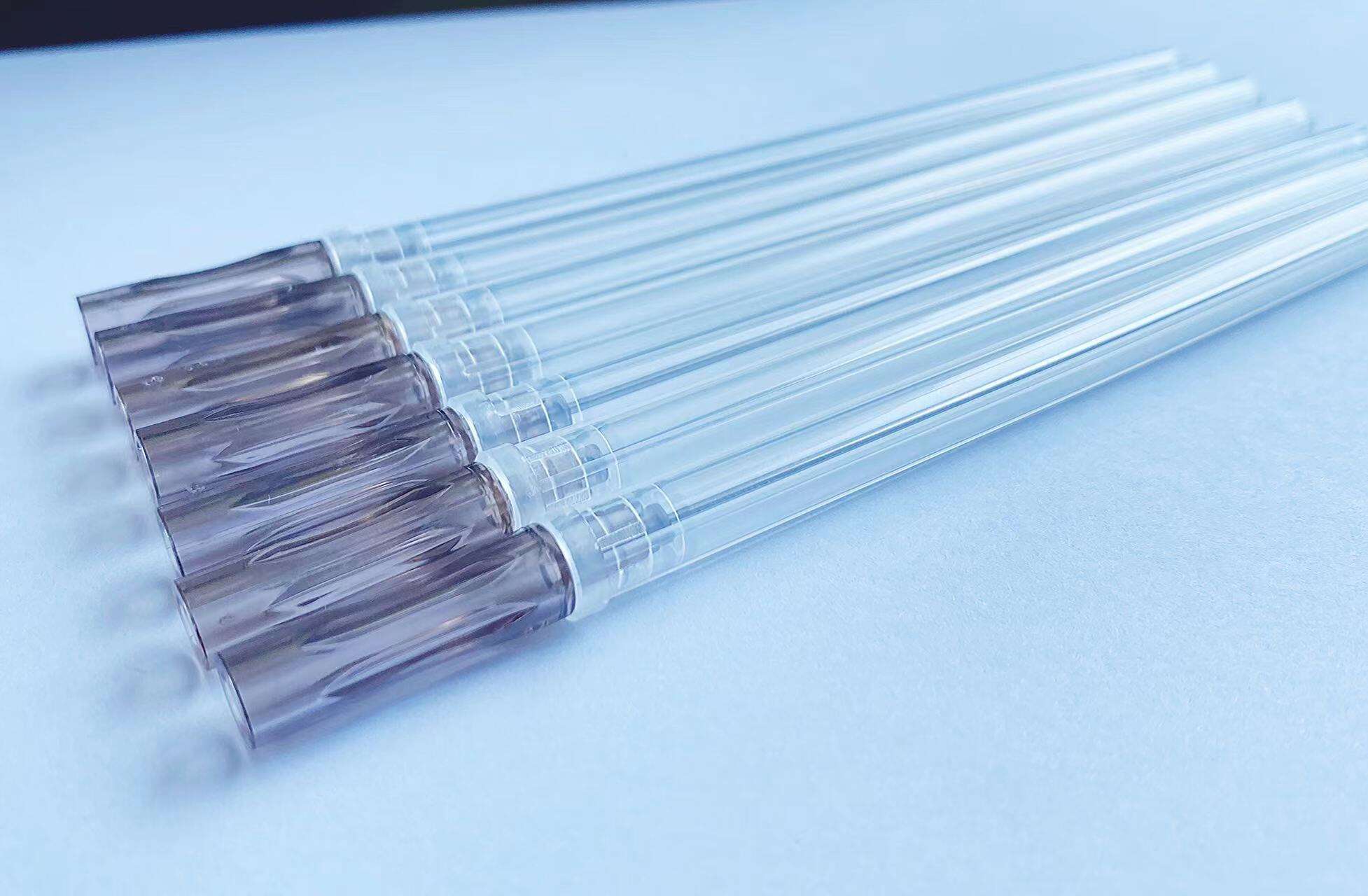

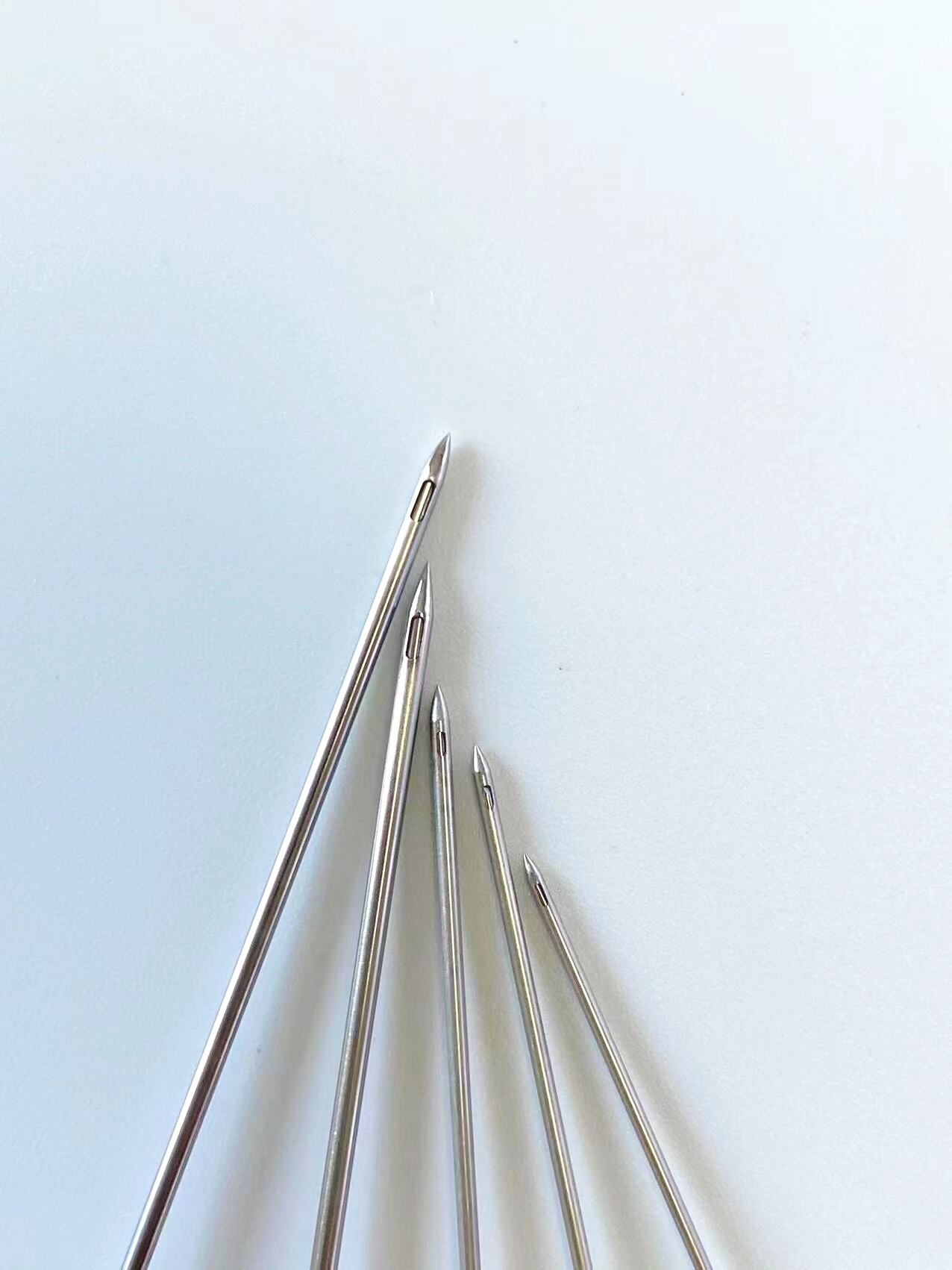

The extensive range of whitacre spinal needle sizes provides medical professionals with unparalleled flexibility to customize treatment approaches based on individual patient characteristics, clinical requirements, and procedural objectives. Available in gauges ranging from 22G to 29G, each whitacre spinal needle size offers distinct advantages for specific clinical scenarios, enabling practitioners to optimize both safety and efficacy for every patient encounter. The 22G whitacre spinal needle sizes deliver rapid cerebrospinal fluid flow rates, making them ideal for procedures requiring quick sample collection or medication administration, particularly beneficial in emergency situations or when working with uncooperative patients. Mid-range options like 25G whitacre spinal needle sizes strike an optimal balance between flow rate and patient comfort, serving as versatile tools for routine spinal anesthesia in adult populations undergoing elective surgical procedures. The finer gauge options, including 27G and 29G whitacre spinal needle sizes, excel in sensitive patient populations such as elderly individuals, those with previous headache histories, or patients undergoing outpatient procedures where rapid recovery is essential. These smaller diameter needles create virtually imperceptible dural defects that seal almost immediately, dramatically reducing the risk of cerebrospinal fluid leakage and associated complications. Pediatric applications particularly benefit from the availability of fine-gauge whitacre spinal needle sizes, as children's smaller anatomical structures and higher risk for complications require the gentlest possible approach. The comprehensive sizing options also accommodate varying anatomical challenges, with practitioners able to select appropriate whitacre spinal needle sizes based on factors such as patient body habitus, spinal anatomy variations, and tissue thickness. This customization capability extends to different medical specialties, with neurologists preferring specific whitacre spinal needle sizes for diagnostic procedures while anesthesiologists may select different gauges for therapeutic interventions. The ability to match needle characteristics to patient needs has revolutionized neuraxial procedures, transforming them from one-size-fits-all approaches to precision medicine applications that prioritize individual patient safety and comfort while maintaining procedural success rates.