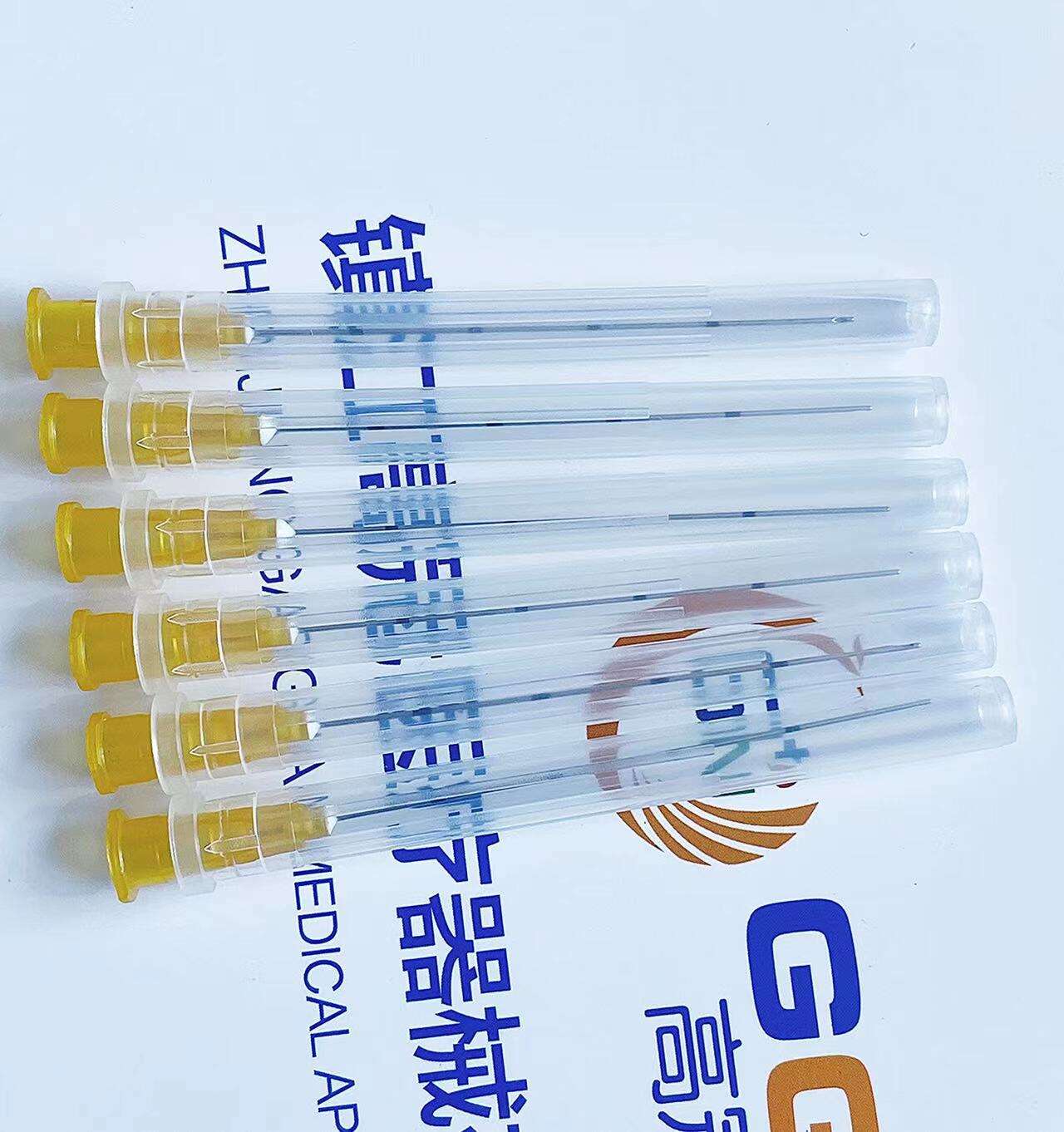

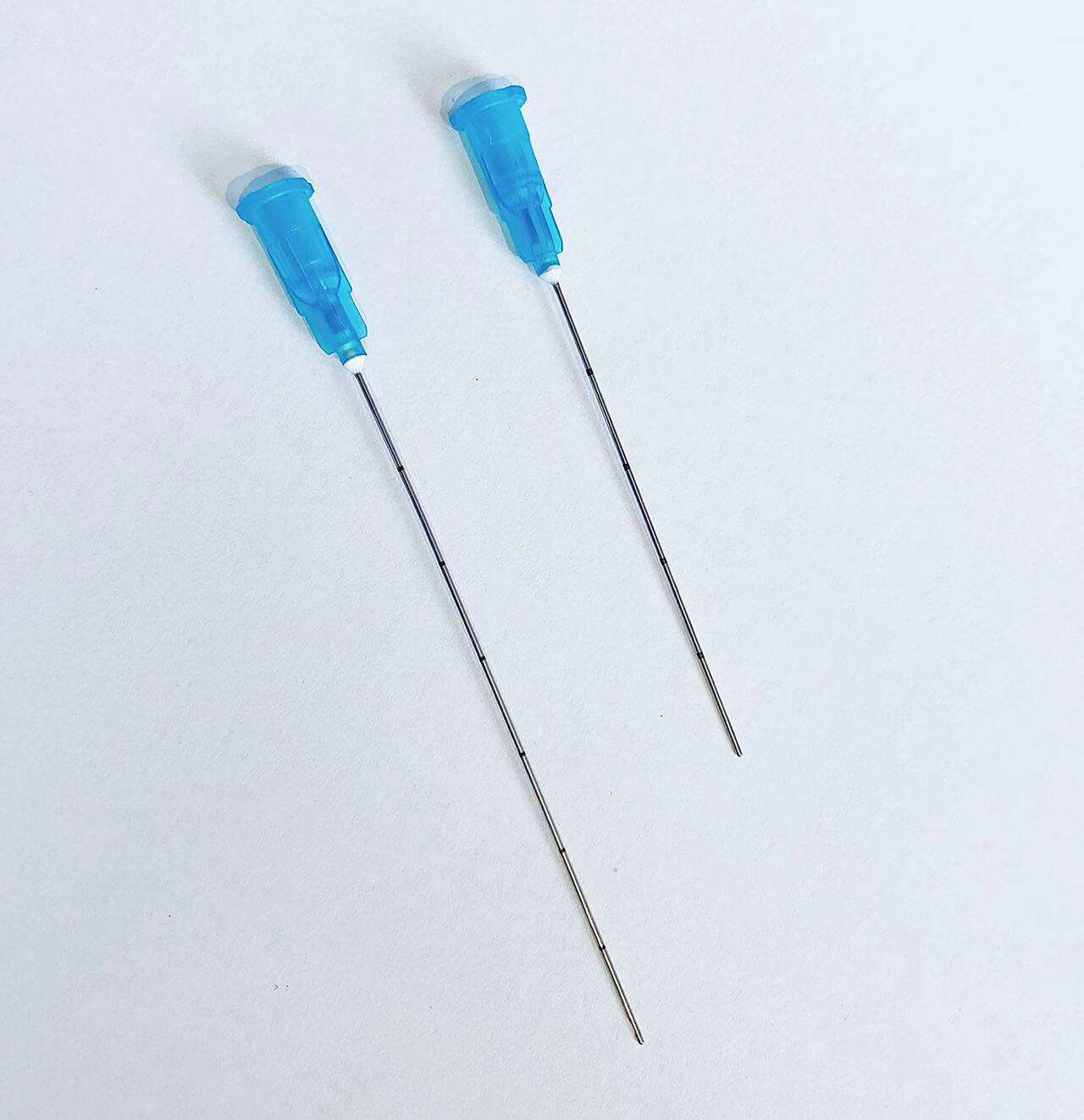

buy plastic blunt tip needle

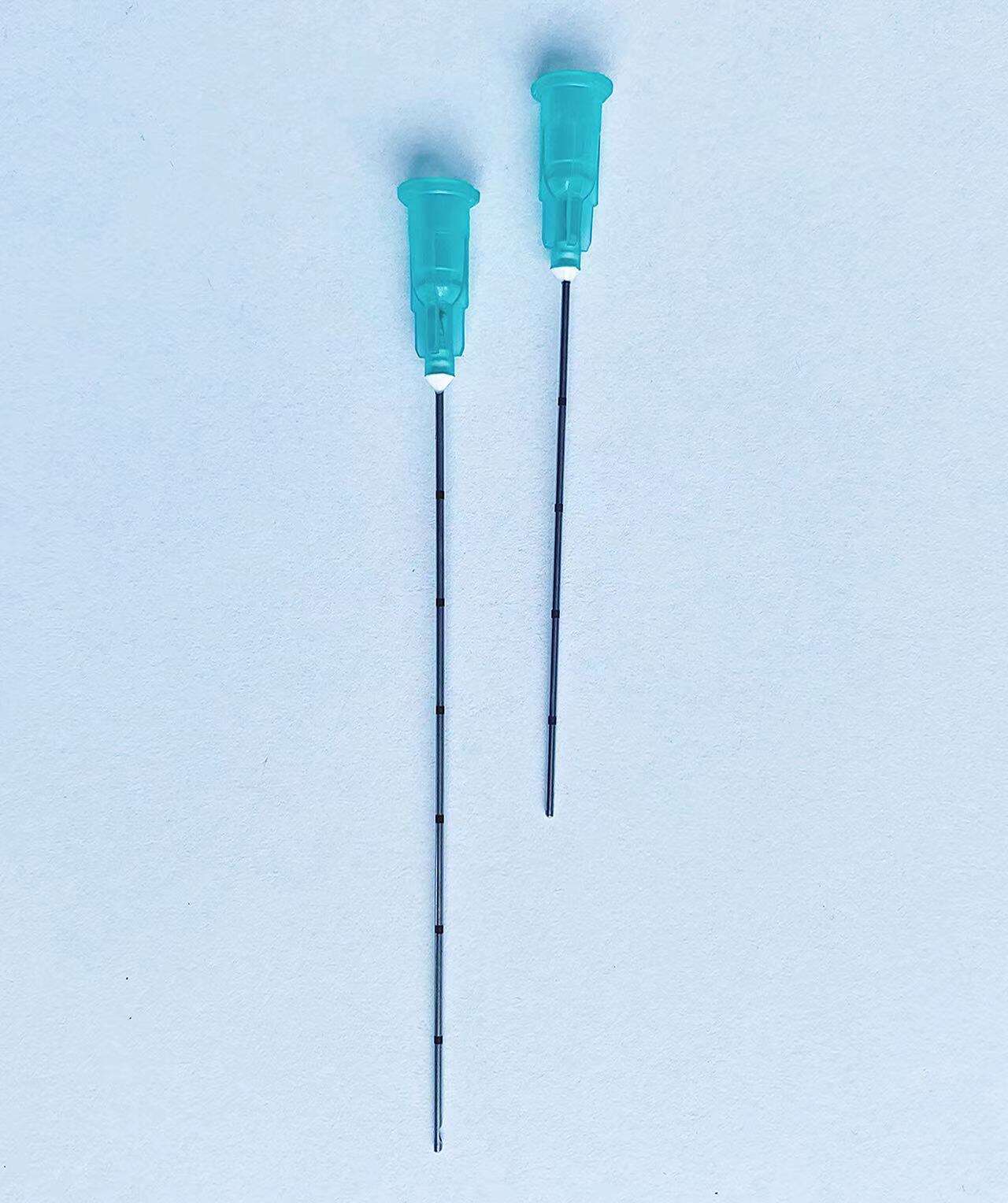

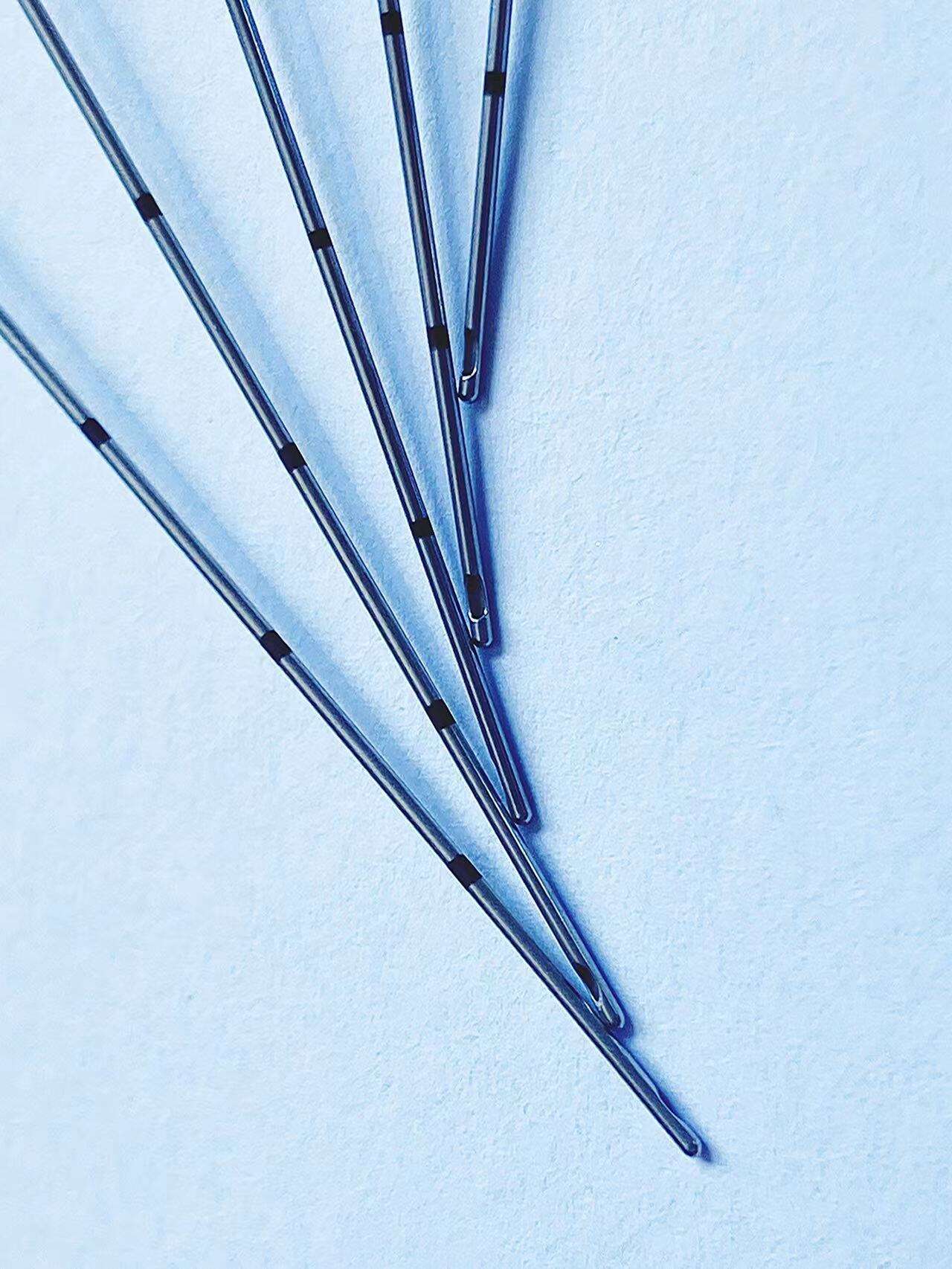

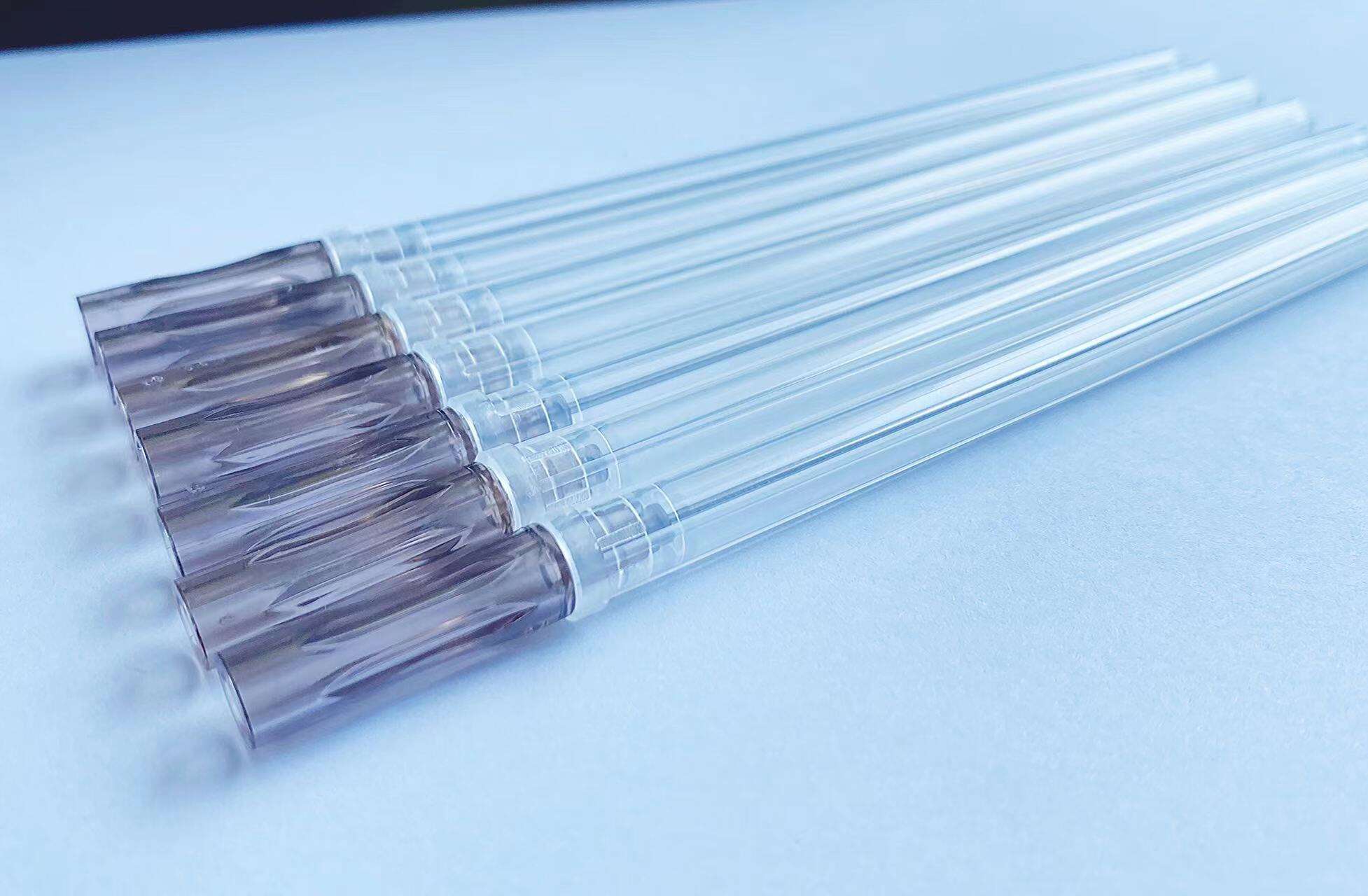

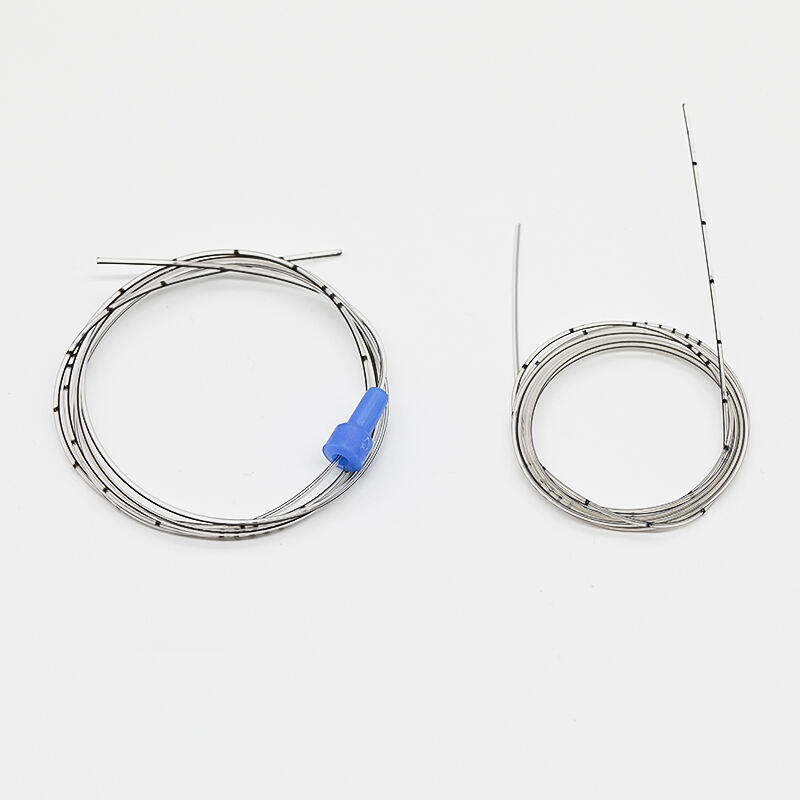

The buy plastic blunt tip needle represents a revolutionary advancement in precision dispensing technology, specifically engineered for applications requiring safe, accurate, and contamination-free liquid handling. These specialized needles feature a unique blunt-ended design that eliminates the sharp point found in traditional needles, making them ideal for sensitive applications where puncturing or damage to materials must be avoided. The plastic construction offers superior chemical resistance and ensures compatibility with a wide range of substances, from adhesives and solvents to pharmaceuticals and laboratory reagents. The buy plastic blunt tip needle incorporates advanced manufacturing techniques that guarantee consistent bore dimensions and smooth internal surfaces, enabling precise flow control and minimal waste. These needles typically feature standardized luer lock or luer slip connections, ensuring universal compatibility with most syringes and dispensing equipment. The technological innovation behind the buy plastic blunt tip needle includes precision molding processes that create uniform wall thickness and optimal fluid dynamics. The blunt tip design prevents accidental needle sticks, reducing workplace safety concerns while maintaining exceptional accuracy in fluid placement. Materials used in manufacturing these needles often include high-grade polypropylene or polyethylene, selected for their chemical inertness and durability. The applications for the buy plastic blunt tip needle span numerous industries, including electronics manufacturing for flux dispensing, automotive assembly for adhesive application, medical device production for sterile fluid handling, and laboratory research for precise reagent delivery. Quality control measures ensure each buy plastic blunt tip needle meets stringent dimensional tolerances and surface finish requirements, guaranteeing reliable performance across diverse operating conditions and extending service life while maintaining cost-effectiveness.