Superior Durability and Cost-Effectiveness

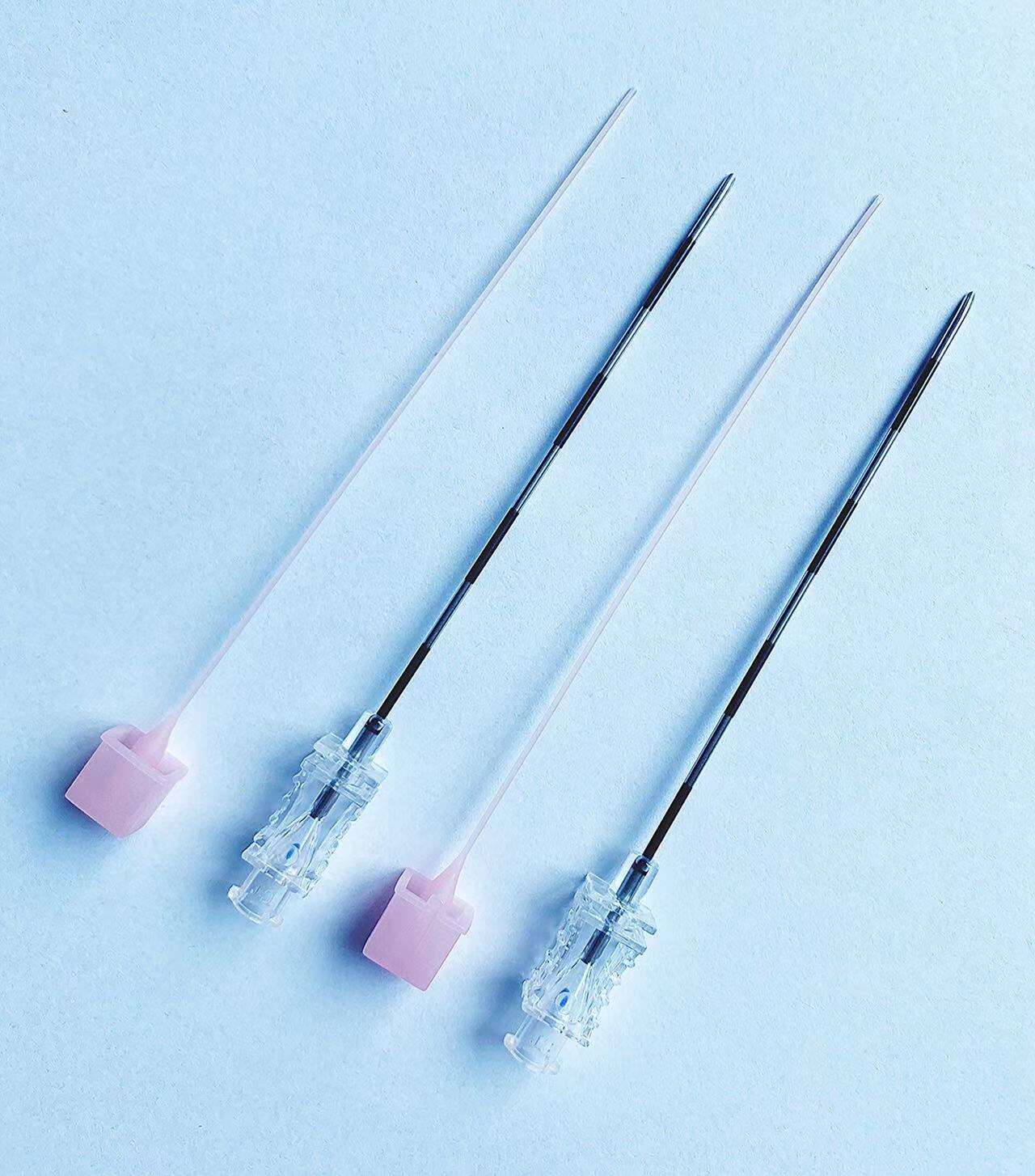

The 18g epidural needle demonstrates exceptional durability characteristics that translate directly into significant cost savings and operational efficiency for healthcare facilities. This superior durability results from advanced metallurgical processes and quality control measures that ensure each needle maintains its performance characteristics throughout its intended lifespan. The needle's construction utilizes premium-grade stainless steel alloys specifically selected for their resistance to corrosion, fatigue, and deformation under normal clinical use conditions. Manufacturing processes include heat treatment procedures that optimize the steel's molecular structure for maximum strength and flexibility, preventing premature failure during demanding procedures. The 18g epidural needle undergoes extensive durability testing that simulates thousands of insertion cycles, ensuring it can withstand the mechanical stresses encountered in real-world clinical environments. Quality assurance protocols verify that each needle maintains its sharpness and dimensional accuracy throughout multiple uses, preventing performance degradation that could compromise patient safety or procedural efficiency. Healthcare administrators recognize the cost-effectiveness of the 18g epidural needle when evaluating total cost of ownership, including factors such as replacement frequency, procedure success rates, and inventory management efficiency. The needle's durability reduces waste generation and disposal costs associated with frequent needle replacements, contributing to more sustainable healthcare practices. Medical facilities report improved budget predictability when using the 18g epidural needle due to its consistent lifespan and reliable performance metrics. The superior durability characteristics extend to the needle's packaging and storage requirements, with protective features that maintain needle integrity during transportation and warehouse storage. Clinical teams appreciate how the 18g epidural needle's durability translates into consistent performance throughout long procedures, eliminating concerns about needle failure at critical moments. The cost-effectiveness benefits become particularly apparent in high-volume clinical settings where needle replacement costs can significantly impact operational budgets. Long-term clinical studies demonstrate that the 18g epidural needle's superior durability contributes to improved patient outcomes through consistent performance and reduced procedure complications related to equipment failure.